The Essentials of Cylindrical Roller Bearings: A Technical Exploration

**Introduction**

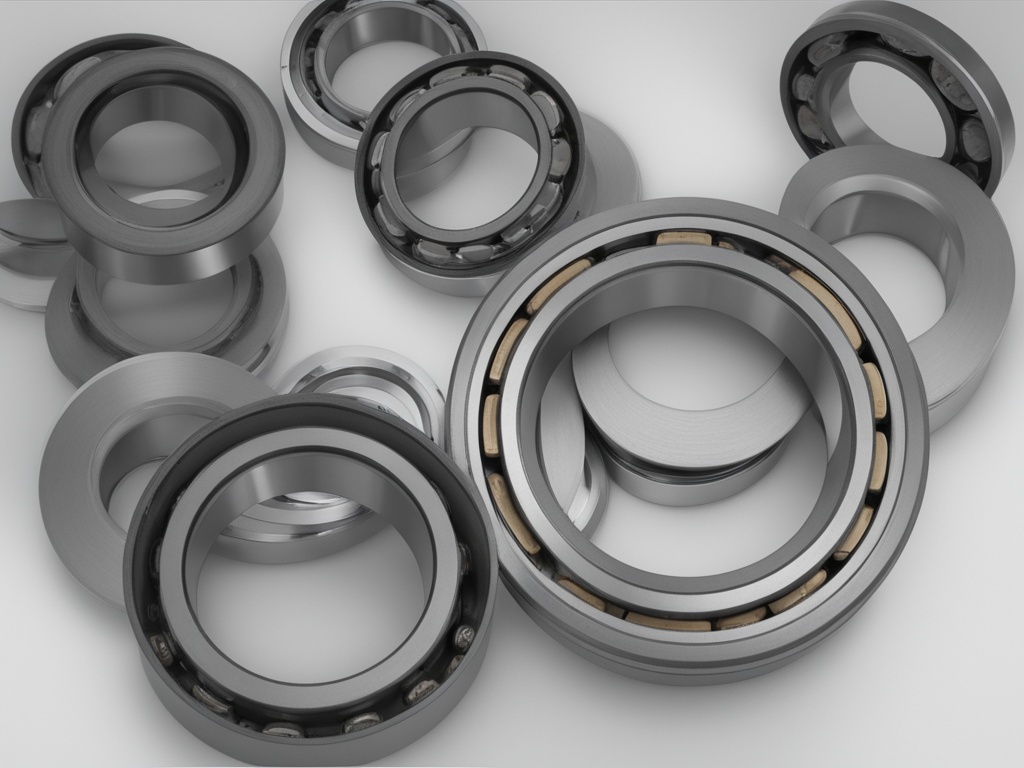

In the intricate world of mechanical engineering, bearings play a pivotal role in enabling smooth, efficient, and durable machine operations. Among various types of bearings, cylindrical roller bearings have emerged as a reliable and efficient choice for numerous applications, especially in heavy-duty and high-speed environments. These bearings are designed to support radial and axial loads, making them ideal for applications that demand both load-bearing capacity and rotational stability. In this article, we delve into the intricacies of cylindrical roller bearings, discussing their construction, working principles, applications, advantages, and challenges.

**Construction and Working Principles**

Cylindrical roller bearings consist of inner and outer rings, known as races, between which the rollers are arranged. These rollers are typically made of high-carbon chromium steel, ensuring excellent strength and wear resistance. The rollers are held in place by a cage or retainer, which ensures that they rotate with the shaft while maintaining their alignment.

The inner race is usually attached to the rotating shaft, while the outer race is fixed to the housing or frame. When the shaft rotates, the rollers roll along the inner and outer races, supporting the load and enabling smooth rotation. The rolling action distributes the load evenly over a larger contact area, reducing wear and tear. Additionally, the clearance between the rollers and the races allows for thermal expansion and contraction, maintaining bearing performance even under varying temperature conditions.

**Applications**

Cylindrical roller bearings find widespread applications in various industries, particularly in large and heavy-duty equipment. Some common applications include:

* Industrial Machinery: Cylindrical roller bearings are commonly used in pumps, motors, gearboxes, and other industrial equipment, supporting radial and axial loads while maintaining high-speed rotation.

* Construction Equipment: These bearings are essential in construction machinery such as bulldozers, excavators, and cranes, enabling smooth operation under heavy loads and variable conditions.

* Automotive Industry: Cylindrical roller bearings are integral to the powertrain components of vehicles, such as engines, transmissions, and differentials, ensuring reliable power delivery and efficient operation.

* Shipbuilding and Maritime Applications: These bearings are crucial in marine equipment, such as propellers, cranes, and pumps, supporting the heavy loads encountered in saltwater environments.

**Advantages**

Cylindrical roller bearings offer several advantages that make them a preferred choice for various applications:

* High Load-Bearing Capacity: Cylindrical roller bearings can withstand significant radial and axial loads, making them suitable for heavy-duty applications.

* Smooth Rotation: The rolling action of the rollers ensures smooth and uniform rotation, minimizing friction and wear.

* High Speed Capability: These bearings are designed to handle high rotational speeds without compromising stability or performance.

* Longevity: With proper maintenance and lubrication, cylindrical roller bearings can last for extended periods, reducing replacement costs and downtime.

* Versatility: Cylindrical roller bearings are available in a wide range of sizes and configurations, allowing them to be tailored to specific applications and requirements.

**Challenges and Considerations**

Despite their numerous advantages, cylindrical roller bearings do have some challenges and considerations that need to be addressed:

* Alignment and Installation: Correct alignment and installation are crucial for ensuring optimal bearing performance. Misalignment can lead to premature wear, increased friction, and decreased bearing lifespan.

* Lubrication and Maintenance: Adequate lubrication is essential for reducing friction and wear in cylindrical roller bearings. Regular maintenance and lubrication ensure smooth operation and extended bearing life.

* Contamination and Debris: Contamination by dust, dirt, or other debris can lead to premature wear and failure. Therefore, it is important to protect bearings from external contaminants and maintain a clean operating environment.

* Thermal Expansion: As cylindrical roller bearings operate under high loads and speeds, they can generate significant heat, leading to thermal expansion. This expansion can affect bearing performance and alignment, so it is important to consider thermal effects during bearing selection and design.

**Conclusion**

Cylindrical roller bearings play a fundamental role in supporting and enabling smooth, efficient machine operations across various industries. Their robust construction, high load-bearing capacity, and smooth rotation make them ideal for heavy-duty and high-speed applications. However, it is crucial to consider factors like alignment, lubrication, maintenance, and contamination control to ensure optimal bearing performance and longevity. By understanding these considerations and implementing best practices, engineers can ensure that cylindrical roller bearings continue to perform reliably, supporting critical operations in a wide range of industrial applications.

13869596835

13869596835