Lip seals - shaft lip seal

... 6203 N1 - Copyright: © 2015 Maurer et al. This is an open access article distributed under the terms of the Creative Commons Attribution License, which ...

NSK bearings are made of high-quality steel, which has been constantly improved by NSK researchers and engineers closely collaborating with steel manufacturers. As a result, the actual life of NSK bearings tends to be considerably longer than bearing life calculated in accordance with ISO standards.

There are a lot of different signs you may run into during day-to-day driving that can indicate a problem with one or more hub assembly on your car. Grinding, roaring, knocking, or popping sounds from your wheels can indicate a bad bearing. These can be constant or only noticeable when you turn; they’re usually not audible unless you’re moving faster than 30 MPH.

Highly accurate bearing life prediction using NSK's Micro-UT Method enables the long-life performance of NSK bearings to be calculated more accurately than before. This calculation method is applied to revise up the basic dynamic load rating of bearings, which is a vital parameter used in application life calculation. For example, for radial roller bearings, it is possible to revise up the basic dynamic load rating to double the equivalent rolling contact fatigue life.

In the longer term, you need to check your wheel hub assemblies if you notice uneven or abnormal wear on your tires or brake components (rotors, pads, and discs). If you let a professional mechanic handle your tire rotations and brake maintenance, they should perform routine hub assembly checks while they do these tasks. If you like to handle your own maintenance, though, it’s especially important to make sure your bearings are in good working condition.

RBC Bearings

Revised basic dynamic load ratings open up new possibilities for customers that want to capitalize on the long-life performance of NSK bearings in their machine design. This is expected to help customers reduce the frequency of component replacement and machine maintenance and potentially downsize machine and unit designs, thereby contributing to the realization of a carbon-neutral society.

Based on this we sucessfully developed the world's first*4 method for calculating rolling contact fatigue life based on the size of non-metallic inclusions in steel.

Thebearingstore

A wheel bearing hub is a pre-assembled unit that includes bearings, seals and sensors. Also called a wheel hub bearing, hub assembly, wheel hub unit or hub and ...

NSK will initially begin to propose solutions based on this technology to select customers, followed by a broad revision of the basic dynamic load rating of its standard bearing lineup.

NSK's unique Micro-UT Method*1 can inspect a volume of steel 3,000 times larger in one-fifth of the time compared to conventional methods*2. This enables efficient collection and analysis of highly reliable statistical data on non-metallic inclusions in bearing steel.

Damaged wheel hub assemblies may fail catastrophically, causing you to lose control of your vehicle. This is a worst case scenario and few people suffer through it. A damaged assembly still impedes the proper functioning of your car, though! It can increase the wear and tear on other vital components including your brakes and tires. By reducing those parts’ effectiveness, a damaged wheel bearing can compromise your safety while you’re on the road.

6203 bore dia is 17 mm. Its out dia is 40 mm. 6203 width is 12 mm. It can offer a highly adaptable and efficient solution for a multitude of mechanical ...

Inches an Inch. Metric of an Inch. Decimal. 1. 1/64 .01563. 2. 1/32 .03125 ... 15/16 .9375. 24.0 mm .94488. 61. 61/64 .95313. 62. 31/32 .96875. 25.0 mm .98425. 63.

BearingCompany near me

Share your videos with friends, family, and the world.

To check individual wheel hub assemblies, you need to look for “play”. “Play” is any looseness in the wheel’s connection to the axle when it’s fully bolted down. You can check for play by grasping the wheel at its top and bottom, and pushing one side while pulling the other. You shouldn’t be able to wiggle the wheel to any significant degree this way; if you can, then the wheel has a dangerous amount of play.

Some people said, a car is a collection of thousands of carefully-designed parts that are needed their attention to maintain with. When it comes to your wheel hub assemblies, you definitely need to muster your patience and go the extra mile to make sure they’re in good working condition; these components are vital in keeping your car safe and efficient.

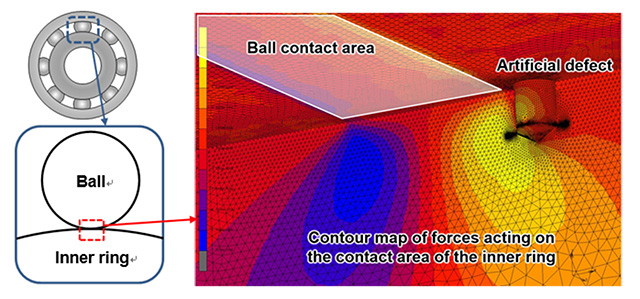

To derive a bearing life calculation method based on the analysis of non-metallic inclusions, NSK developed a unique rotational testing method that involves introducing artificial defects simulating non-metallic inclusions of various sizes into rolling bearing raceways.

Bearingmanufacturers

When you discover a damaged wheel hub assembly, make sure it’s replaced with either OEM parts from your manufacturer or quality aftermarket replacement parts like WJB’s that meet the same standards. Making sure your vehicle is running on healthy wheel hub assemblies is a vital part of keeping your vehicles – and you – safe on the road.

XHTML: You can use these tags:

Fortunately, a damaged hub assembly is easy to spot once you have your wheels jacked up off the ground. If at all possible, check your wheels two at a time – either both front wheels or both back ones. You can often spot a broken wheel bearing simply by comparing the behavior of two wheels after you spin them at the same time. If one of them shudders, slows down, or grinds to a stop before the other, it likely has a bad bearing.

LAW ENFORCEMENT SUBMISSION FORM ... 18000 W. Nine Mile Rd. Suite 500. Southfield, MI, 48075. . . Phone: ( ...

Accurate bearingreviews

Built under strict quality control standards; Tested for impact, wear and fatigue to ensure quality and durability; Manufactured in ISO9002 Certified facility.

AlpineBearing

This technology has enabled NSK to revise up the basic dynamic load rating of its bearings and further enables customers to design machines and vehicles that make full use of the long-life performance of high-quality NSK bearings.

NSK began its journey manufacturing the first bearings in Japan in 1916, and has since developed into a global organization researching, designing, and manufacturing Motion & Control™ solutions essential for mobility and industrial applications. NSK is the top supplier of bearings in Japan and is the third largest supplier in the world by market share.

We succeeded in reproducing specific modes of failure as intended and further created a simulation*3 capable of reproducing and analyzing the stresses around the artificial defects to futher clarify the mechanism of flaking fatigue.

The rolling contact fatigue life of bearings is closely related to the size and quantity of non-metallic inclusions in the steel. Depending on the steel, the amount and distribution of non-metallic inclusions can vary widely.

Bakerbearing

Although modern wheel hub assemblies (also known as wheel bearings) are designed to last as long as your car, they’re subjected to such tremendous strain that hub damage is fairly common. Most drivers will have to deal with a damaged hub assembly at some point in their vehicle’s lifetime.

NSK Ltd. has developed the world's first method to highly accurately predict the life of a rolling bearing based on statistical data (size and quantity) of non-metallic inclusions (impurities) in the steel.

Accurate bearingcatalog

Our responsive products and technologies enhance automotive performance and industrial productivity while reducing energy consumption to unprecedented low levels. In the early 1960s, we set our sights outside Japan and have established over 200 business locations in 30 countries alongside a vast network of joint ventures and partnerships in all corners of the world.

In order to better enable customers to make full use of the long-life performance of NSK bearings in their machine design and pursue carbon neutrality, we needed a technology that could calculate rolling fatigue life with a high degree of accuracy.

20241120 — Turning a Wheelbarrow Into a Car! · More videos you may like · Reels · Related Pages.

Identify the correct replacement seal. The seals are arranged by shaft size from smallest to largest. If you are unable to identify the seal, it will be ...

Though wheel bearings are low-maintenance parts, they are important safety components of a vehicle's braking, steering, and suspension systems. The one-piece ...

8613869596835

8613869596835