Lorf Hostel&Apartments, Krakow - lorf

Mobile mechanics- We dispatch sub contracted mechanics to customers home or work versus customer going to the shop to have their cars serviced.

Locating and non locatingbearing

Currently serving: Scarborough, North York, Downtown Toronto, Brampton, Mississauga, York, Etobicoke, East York, Oakville, See More…

It’s important to note that if you start to hear strange noises coming from your wheels, or if your vehicle starts to vibrate at certain speeds, it may be time to get your wheel bearings checked out. Catching a problem early can save you a lot of money and hassle down the road.

Bearingarrangement types

Various Bearing Seats Because a bearing can choose different bearing seats, and a bearing seat can choose different types of bearings at the same time, so there are many kinds of bearing seats. Bearing seats are fast, easy and excellent. Many large foreign bearing companies also have their own type of bearing seats. However, the same bearing type is marked differently in different company samples. For different application occasions of standard bearing seat, special bearing seat with different materials such as gray cast iron, nodular cast iron and cast steel, stainless steel and plastic can be selected. Today, let's learn about the bearing seat of the rotary table. Rotary disc bearing pedestal is a kind of large and super large bearing pedestal which can accept comprehensive load and has special structure. It has the characteristics of compact structure, sensitive rotation and convenient device maintenance. Where there is a bearing, there must be a support point. The internal support point of the bearing is the axis, and the external support is often referred to as the bearing seat. Compared with the common bearing seat, the rotary disk bearing seat has the following obvious characteristics: 1. Shape size The diameter is usually 0.4 cm to 10 m, and the maximum is 40 m. 2. High bearing capacity Usually it can accept axial load, radial load and overturning moment load together. 3. Low speed Task speed is less than 10r/min, and in a few cases do not turn one after another, only rotate in a certain angle, do swing motion. 4. Hole with bearing seat device It can be fastened to the upper and lower supports with screws. 5. No central axis The inner ring or outer ring is equipped with gears for rotary drive. 6. Installation with smooth oil hole and seal. The important construction modes of the rotary disc bearing seat can be distinguished as four-point contact ball bearing seat, double row angular contact thrust ball bearing seat, inserting cylindrical roller bearing seat, inserting tapered roller bearing seat, and three rows of cylindrical roller with rotary disc bearing seat. Rotary disc bearings are widely used in large-scale rotary installation of lifting and transportation machinery, mining machinery, construction machinery, port machinery, marine machinery and high-precision radar. If you want to know more about bearings, you can contact us. Our mailbox is yuki@ywsbearing.com .

Today, let's learn about the bearing seat of the rotary table. Rotary disc bearing pedestal is a kind of large and super large bearing pedestal which can accept comprehensive load and has special structure. It has the characteristics of compact structure, sensitive rotation and convenient device maintenance. Where there is a bearing, there must be a support point. The internal support point of the bearing is the axis, and the external support is often referred to as the bearing seat. Compared with the common bearing seat, the rotary disk bearing seat has the following obvious characteristics:

Bearingdesign calculations PDF

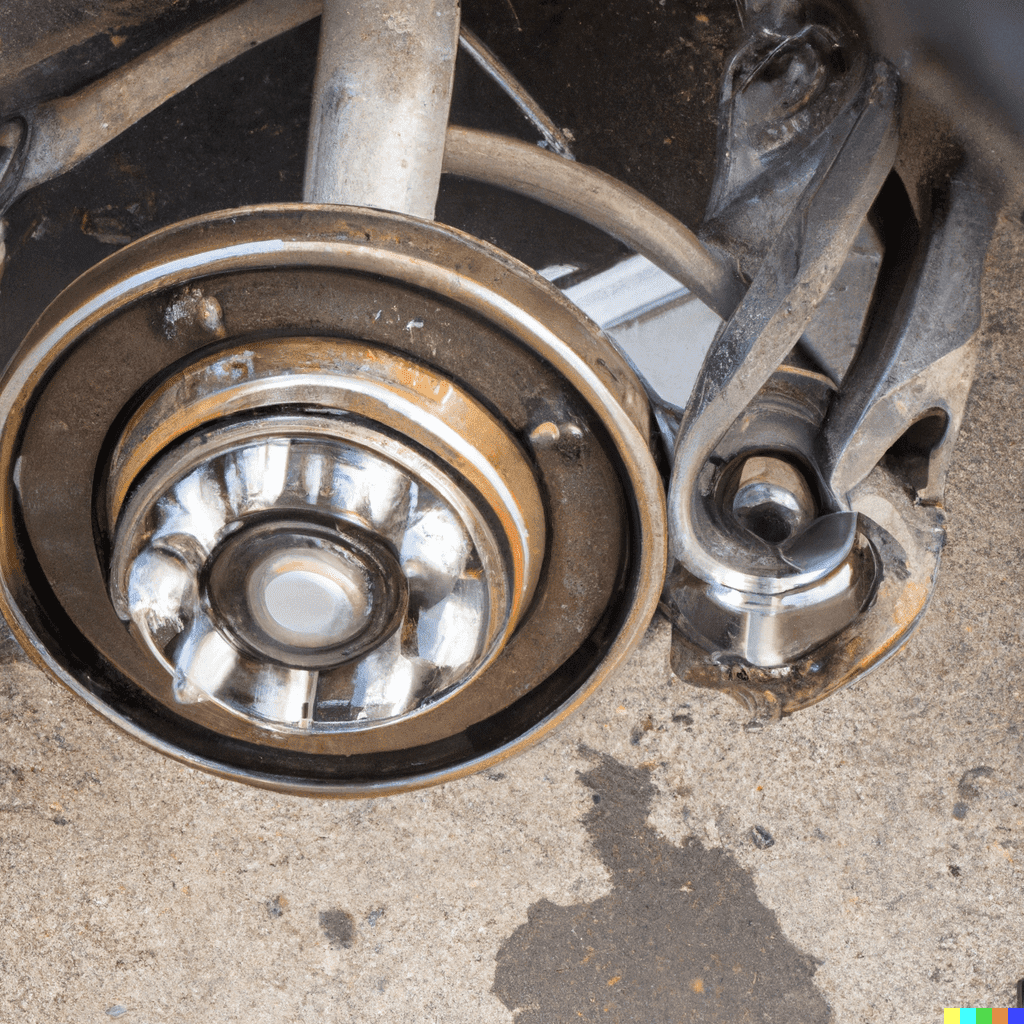

create a sub heading for: When it comes to replacing wheel bearings, there are a few other components that may need to be replaced as well. One of the most common parts that is replaced along with wheel bearings is the hub assembly. The hub assembly is the part of the wheel that holds the wheel bearings and connects to the suspension system. When the wheel bearings fail, it is often recommended to replace the hub assembly as well, as it can be difficult to remove the old bearings from the hub.

It is not safe to drive with bad wheel bearings. If a bearing fails while you are driving, it can cause the wheel to come off of the vehicle, leading to a serious accident. It’s important to have any issues with your wheel bearings addressed as soon as possible.

Rotary disc bearings are widely used in large-scale rotary installation of lifting and transportation machinery, mining machinery, construction machinery, port machinery, marine machinery and high-precision radar.

Bearingarrangements pdf

It is also worth noting that if the wheel bearings have failed due to issues with the suspension or steering system, those components may need to be inspected and repaired as well. In some cases, worn or damaged bearings can cause additional wear and tear on other parts of the vehicle, so it is important to have a mechanic inspect the entire system to ensure all necessary repairs are made.

Floatingbearing

Because a bearing can choose different bearing seats, and a bearing seat can choose different types of bearings at the same time, so there are many kinds of bearing seats. Bearing seats are fast, easy and excellent. Many large foreign bearing companies also have their own type of bearing seats. However, the same bearing type is marked differently in different company samples. For different application occasions of standard bearing seat, special bearing seat with different materials such as gray cast iron, nodular cast iron and cast steel, stainless steel and plastic can be selected.

In the most basic terms, a wheel bearing is a crucial component of your vehicle’s suspension system. It’s a small metal ball that helps your wheels spin smoothly as you drive. Without properly functioning wheel bearings, your ride will be anything but smooth.

The answer to that question depends on a few factors, including the make and model of your vehicle and how you drive. In general, however, most vehicles will need new wheel bearings every 130,000 km to 160,000 km

The important construction modes of the rotary disc bearing seat can be distinguished as four-point contact ball bearing seat, double row angular contact thrust ball bearing seat, inserting cylindrical roller bearing seat, inserting tapered roller bearing seat, and three rows of cylindrical roller with rotary disc bearing seat.

Task speed is less than 10r/min, and in a few cases do not turn one after another, only rotate in a certain angle, do swing motion.

Bearingarrangement for vertical shaft

The cost of replacing wheel bearings in Canada can vary depending on different factors such as the type of bearings, make and model of the car, and local labor costs. However, it’s important to prioritize the safety of your vehicle by having any issues with your wheel bearings addressed promptly. Regular inspections, following the recommended maintenance schedule, and upgrading to high-quality bearings can help prolong the lifespan of your vehicle’s bearings. If you’re in need of a reliable mechanic to inspect or replace your wheel bearings, consider getting a free quote with Uchanics, who offer mobile wheel bearing replacement conveniently at the comfort of your home.. Don’t wait until it’s too late – ensure the safety and smooth operation of your vehicle by taking care of your wheel bearings today.

Wheel bearings are a critical part of keeping your vehicle running smoothly, but they can wear out over time, causing various issues like vibrations, noises, and other problems. If you’re a Canadian driver wondering about the cost of replacing your wheel bearings, the answer varies. The cost depends on factors such as the type of bearings, your car’s make and model, and the local labor costs.

• Follow the recommended maintenance schedule for your vehicle and have your wheel bearings inspected regularly• Avoid overloading your vehicle, as this can put extra strain on the bearings• Keep your tires properly inflated, as driving on underinflated tires can cause increased wear on the bearings• Avoid driving through deep water or in extreme weather conditions, as this can cause damage to the bearings• If you notice any strange noises or vibrations coming from your wheels, have them checked out as soon as possible• If you frequently drive on rough roads or in mountainous terrain, consider upgrading to higher quality wheel bearings to increase their lifespan.

If you need to replace all the wheel bearings on your vehicle, expect to spend anywhere from $800 to $1400. Unless you have a warranty plan that covers this cost, it may be more expensive than you anticipate.

• Grinding or growling noise coming from the wheel area• Vibration or shaking while driving, especially at high speeds• Difficulty turning the vehicle• Uneven tire wear

Overall, the cost of replacing wheel bearings varies based on different factors. It’s crucial to obtain an accurate estimate from a trusted mechanic before proceeding with the repair. Investing in high-quality wheel bearings and professional installation can save you money over time by reducing the need for frequent repairs.

In addition to the hub assembly, other parts that may need to be replaced when changing wheel bearings include the dust cap, cotter pin, and axle nut. These components can wear down over time or become damaged during the removal and installation of the wheel bearings. It is important to replace them to ensure the new bearings are installed correctly and securely.

Replacing front wheel bearings is typically more expensive and the total cost can range from $385 to $700. The average labor costs range from $225 to $350, and the average parts cost is between $160 and $350.

On average, the total cost can range from $350 to $650. Parts needed to replace rear wheel bearings can cost between $150 and $300. Labor costs usually range between $200 and $350.

8613869596835

8613869596835