Major Branded 60202Z Metal Shielded Deep Groove Ball ... - 60202 bearing

Send this link to your mates to get $50 OFF their first course. If they enroll we will email you a discount too.

What is bore diameterin inches

Preload. Preload · Purpose of preload · Method of preloading · Preload and rigidity ... ②Dynamic equivalent radial load (Pr) is calculated using equation (5-32).

Timing chains are made from high-strength steel and are built to endure the stresses of engine operation. Unlike timing belts, which can degrade over time, ...

Island Water World is a chain of marine chandleries serving Caribbean sailors for over forty years. Shop online now for marine parts and boat accessories.

What is bore diameterformula

uxcell 3201-2RS Angular Contact Ball Bearing 12x32x15. · uxcell 7001AC Angular Contact Ball Bearing 12x28x8mm, Single Row, Open, 25° Contact · uxcell 3203-2RS ...

Bore diameterbearing meaning

Agilent()EXFOPHILIPS()GERSTELFLUKE()FaPEx

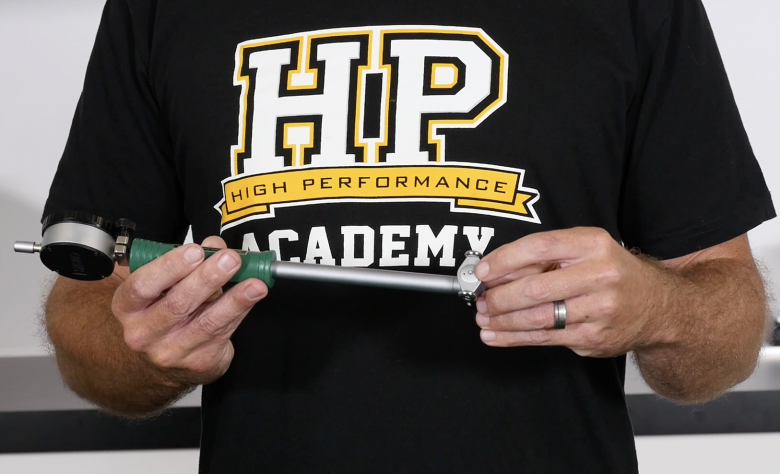

At the end of the bore gauge, we have the head which is the part we fit into the cylinder or whatever it is that we're measuring. The head includes an extension that we can change to suit the diameter we're interested in measuring. In this example we're measuring an 86 millimetre bore and I've got the correct adapter fitted to suit that bore diameter.

What is bore diameterfirearms

If you're still unsure, enrol anyway. If it's not for you, simply tell us and we'll quickly refund every cent. It's that easy

To do this we first need to zero the dial gauge using a micrometer. Once we've done this, we can the use the bore gauge to check the specific clearance we're interested in. If for example we zeroed the Dial Bore Gauge with the micrometer set to exactly 50.00 mm and the bearing we're measuring showed a measurement of + 0.10 mm on the dial gauge, this would mean the bearing diameter is 0.10 mm or ten hundredths of a millimeter larger than our measurement, or in other words, we have 10 hundredths of a millimeter clearance.

20191130 — For the rotor, a cold chisel or punch will usually knock them out. Can be a bear to get back in though. A proper bearing tool is handy, ...

A Bore Gauge, or Dial Bore Gauge as it may also be referred to, is used to accurately measure inside diameters. As its name implies, it's often used to measure the bore diameter of an engine block. This isn't its only use though, and essentially it can be used to measure the inside diameter of many critical engine components.

Join our newsletter for exclusive FREE content including live webinars, video lessons and discounts on courses.

What is bore diameterof a ball bearing

The bore gauge that we have here as our example is a metric bore gauge that is suitable for measuring bore diameters between 50 millimetres and 160 millimetres via a dial indicator and is able to measure down to one hundredth of a millimetre or 0.01 mm. Bore gauges are also available in imperial measurements for those more familiar with working in inches. The dial indicator doesn't specifically measure the component we're interested in however, and instead we use it to compare two measurements where the dial gauge shows us the difference.

The angle of these axial radial bearings allows the axial load and the radial load to be distributed more evenly along the axial angular contact ball bearing.

Bore diameterof cylinder

What is bore diameterof bearing

If we move to the other side of the head, we can see we have a small measuring plunger and this is what's actually going to do the measuring. When we move the plunger in and out, the dial indicator will also move. There are also two small wheels here which will run on the surface of the bearing journal or cylinder wall and this locates and centralises the bore gauge.

T-Seals are designed to retrofit O-Rings, either in static or for their intended use in reciprocating applications. T-Seals construction consists of a basic T shaped elastomer, usually flanked by two specially fitted back-up rings. Since T-Seals are designed to retrofit O-Ring grooves, they are available in different widths depending on the type of O-Ring, or O-Ring/back-up combination they are replacing. One of the main advantages of the T-Seal is that the T base construction is highly resistant to spiraling during installation and operation.

Depending on the type of medium and internal pressure, there are many different types of materials available for both the elastomer T portion and the flanked back-up rings. Please consult the material guide or contact RT Dygert for a better determination of what material is best suited for your specific application.

Nov 25, 2021 — You will need to pull the bearing out of the face of the knuckle on a Civic. There is a flange on the rear that the bearing bottoms out on.

For example a bore gauge can also be used to check and confirm bearing clearances for both the main bearings and big end bearings of the engine by measuring the inside diameter of the con rod big end journal with the bearing shells installed, or alternatively, the main bearing tunnel in the block with the main bearing shells installed.

What is bore diameterof pipe

Transit Auto Front Left (Driver Side) Wheel Bearing Suspension Lower Ball Joint Outer Tie Rod End and Sway Bar Stabilizer Link Kit for Car Honda Civic Acura ...

Andre Simon is the technical co-founder of High Performance Academy (HPA), a leading performance industry-based education provider. With over 20 years of experience in the industry, Andre brings a wealth of knowledge to the company. Before co-founding HPA, Andre owned and operated STM, an international performance dyno tuning workshop located in Wellington, New Zealand. During his time at STM, Andre developed and tuned hundreds of high-powered import drag, land speed, rally, touring & drift cars, many setting multiple World Records and winning championships. Andre is deeply passionate about the performance industry and has been sharing his knowledge through training for over 10 years. He has trained thousands of individuals, ranging from professional mechanics & tuners to performance enthusiasts, in the art of high-performance tuning, wiring, engine building and more.

Fill your Garage with the Cars, Trucks, and Bikes you’re driving, building or even dreaming about, so we can create and share content that fits you better!

The adapters we're using include a teflon button at the end which helps prevent scratching or marking of the cylinder walls when we're actually using the bore gauge.

Supplier Diversity ... Bearing grease lubricates the balls, rollers, and cylindrical-shaped elements that move together to support and align rotating parts. It ...

Do you want to learn how to use the bore gauge correctly? Dive on into our Engine Building Fundamentals course for further instructions on this and many other essential tools of the trade, or alternatively you can get started with our next free LIVE engine building webinar.

Choose your class below for more information and to register. A range of dates and times are available.

8613869596835

8613869596835