MB-10 Tablets | Cbond - mb10

MBmarble Resurfacing

Never reuse any wheel bearing (sealed or tapered) that’s loose, worn, noisy or shows any signs of wear. Trying to fix a loose or damaged wheel bearing can result in an accident and severe injury. Even if a pro suggests repairing a bearing, don’t let them.

MBZero

3. FLOORS: Target an area of approximately 10 sq. ft. In the middle of the target area, sprinkle approximately 2 oz. of product in a circular pattern slightly smaller than the diameter of the floor machine. Using a hog’s hair pad, position the floor machine with water on top of the powder. The machine cannot exceed 175 RPM for best results and needs at least 1.5 HP. Release 5 seconds of water and swiftly swing the machine back and forth over the targeted area to evenly spread the slurry. (Note: keep the slurry thick; not too wet) Polish slowly with a spiral motion moving from one end of the targeted area to the other and back. Continue polishing for 3-4 minutes. Then check the surface with a squeegee. You should have a high polish at this point. Next release just enough fresh water onto your target area to make vacuuming the used slurry easy. Then clean with a neutral cleaner such as MB-1 Floor Cleaner or MB-15 Stoneglow. Now repeat this process on next section.

In my 50 years in the auto repair industry, I can’t recall one good story about wheel bearings. Most involve some sort of brake system failure, tires exploding, or fire from a seized red-hot bearing igniting axle grease. Bad wheel bearings should not be ignored.

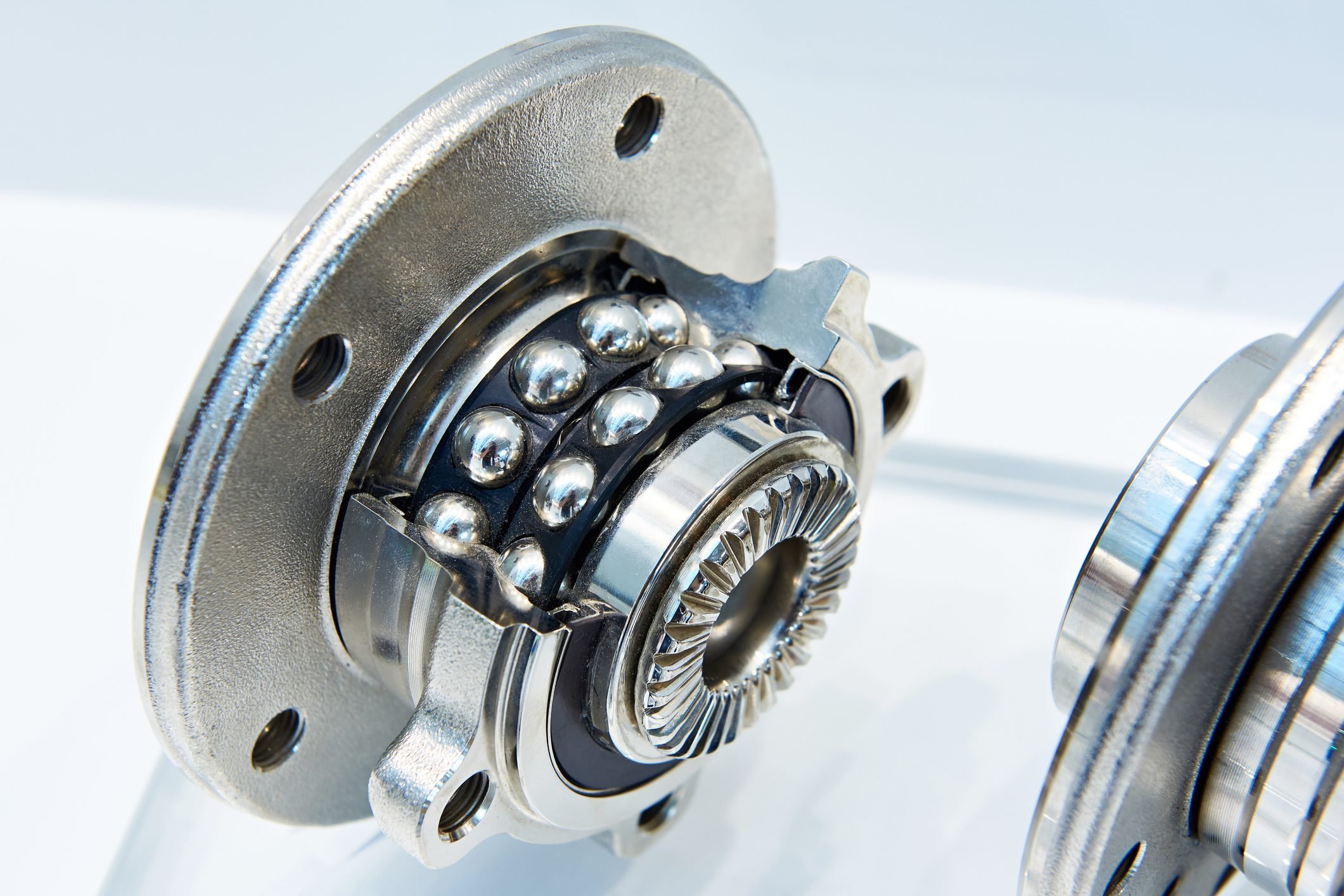

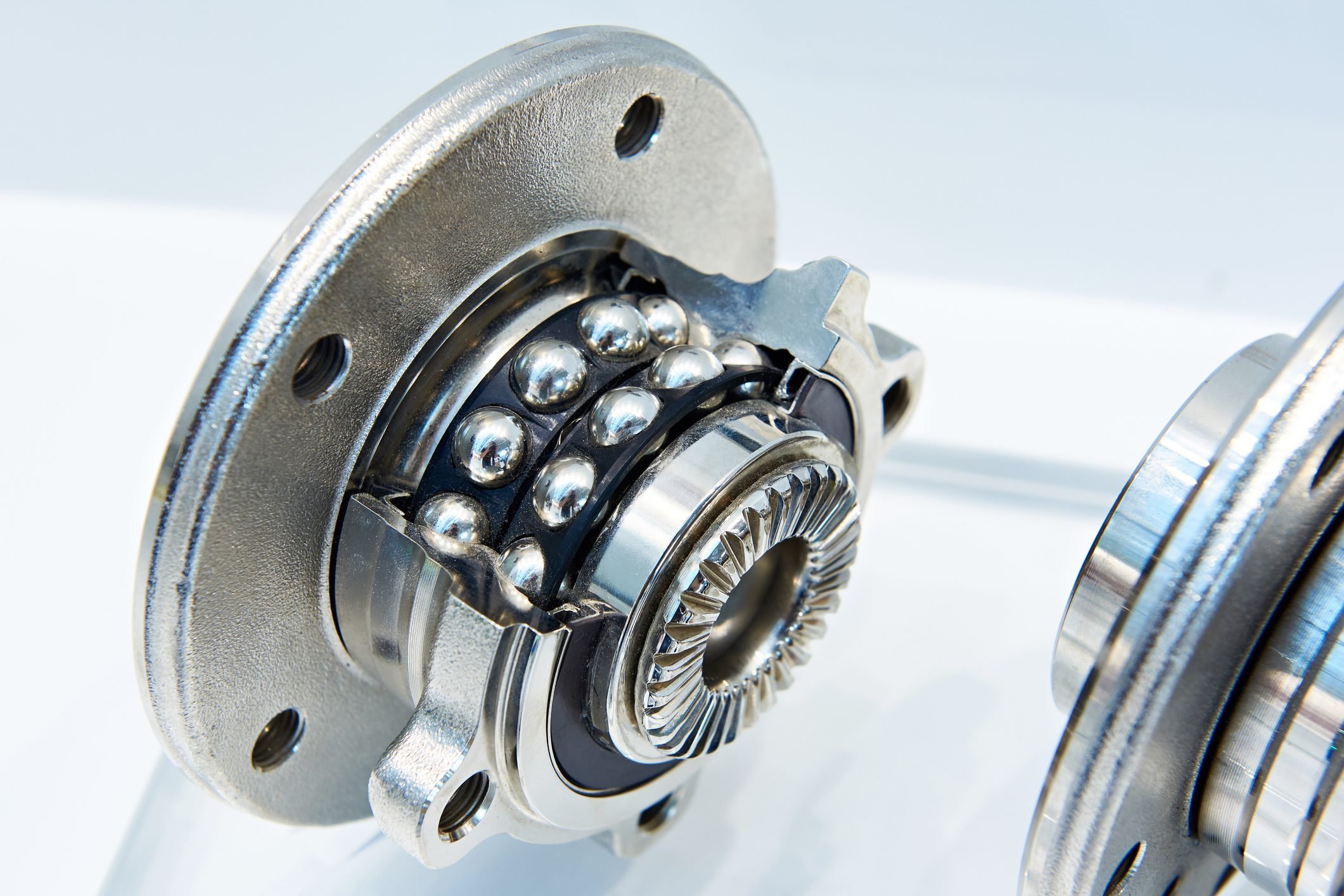

On modern front- and four-wheel-drive cars, wheel bearings are a set of permanently sealed, precisely machined steel ball or straight roller bearings. The balls or rollers are encased in a “cage” that supports the bearings, allowing them to rotate freely.

MBStone sealer

MB-20 Granite Polishing Kit

Wheel bearings allow cars and trucks to run smoother and more efficiently by reducing friction and supporting vehicle weight.

The average cost to replace a sealed wheel hub bearing is around $350 per wheel. However, depending on the make and model, the shop labor rate ($47 to $215 per hour, according to AAA) and any additional damage could push the cost beyond $1,000 per wheel.

My opinion? If your vehicle has more than 50,000 miles or has been driven in harsh conditions, then it’s logical to replacing wheel bearings on both axles. However, if your vehicle has low mileage and the other bearing is in good condition, replacing only the damaged bearing should not be a problem.

MBstone Care

Under normal driving conditions, wheel bearings should last 85,000 to 100,000 miles. They can fail for several reasons, including:

The following are AVERAGE directions. Different stones may require different techniques. If you are in doubt, don’t hesitate to call

An awesome wet polishing powder that will not etch surfaces with splatter. Formulated for calcite-based stones and terrazzo.

Mbstone pro

Driving on a bad or failing wheel bearing is dangerous. If ignored, it can quickly turn into a safety issue and an expensive repair.

mb-11 marble polishing powder

4. COUNTER TOPS: Target an area approximately 4 sq. ft. On the targeted surface, sprinkle 1 tablespoon of productin a circular pattern slightly smaller than the polishing pad you are using. Spray some water on the powder and overthe rest of the targeted area. Set the speed of the right-angle grinder/polisher (variable speed is a MUST) to the slowestspeed. Using a hog’s hair pad, move the machine over the targeted area slowly, applying steady pressure. Check thesurface for results after approximately 2 minutes. If you have a high polish, semi-flush the section and pull the slurrydown to next section and repeat.

Older rear-wheel-drive cars or trailers use a set of two tapered roller bearings that face each other. These should be routinely serviced every 20,000 miles, or once a year.

However, on some vehicles, it can be less than $100 per wheel. And you can save hundreds in labor if you DIY. If you don’t have the tools, most auto parts stores will lend you the specialty tools and equipment needed.

The cage and rollers are held together inside a hardened metal ring called a “race.” The seal keeps grease in and damaging water and debris out. Wheel bearings are installed inside, and secured to, the suspension, either by press-fit, bolts or a snap-ring. Once mounted, the wheel bearing rides on the axle shaft, allowing the tire/wheel to spin effortlessly.

All orders are processed within 3-5 business days (excluding weekends and holidays) after receiving your order confirmation email. You will receive an email notification when your order has shipped. Shipping times will vary depending on your location; if you need your prodcut ASAP there are expedited shipping options.

I’ve replaced hundreds, if not thousands, of wheel bearings. One thing I’ve learned: A bad wheel bearing always gives an indication it’s failing. These include:

mb-22® e-z polishing powder

NOTE: Whether you DIY or your mechanic replaces the bearing, always install a new axle hub nut. Most hub nuts are prevailing torque fasteners. They’re used on critical components, like securing axle shafts to hub bearings, where a loose nut could lead to disastrous consequences.

We are no longer supporting IE (Internet Explorer) as we strive to provide site experiences for browsers that support new web standards and security practices.

8613869596835

8613869596835