Miniature Ball Bearing - Small Bearings Latest Price, ... - small ball bearing

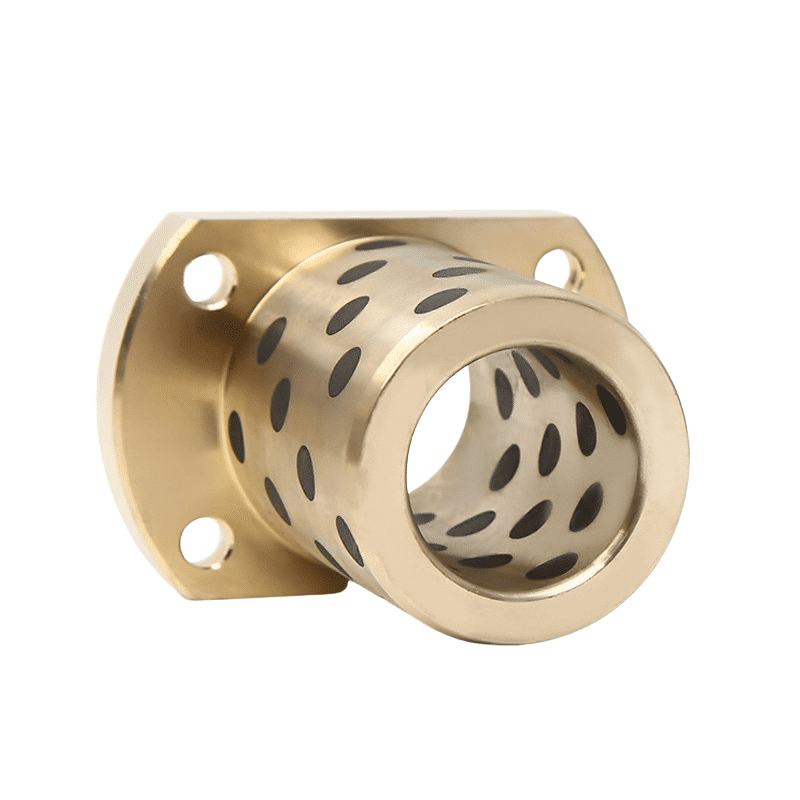

Self-lubricating slide bearings with dry lubricating. On the bronze alloy with lubricating, solid lubricant Graphite, PTFE, or MoS2.

The model of self-lubricating graphite copper sleeve is digital group, that is, inner diameter + outer diameter + length, such as inner hole 30, outer diameter 38, the model of self-lubricating graphite copper sleeve of length 30 is 303830.

Product description. The 23960-B-MB FAG is a spherical roller bearing. This bearing type has a solid inner ring, which runs on two rows of symmetrical rollers ...

These bushings can support high loads and are highly durable. They are made from robust materials such as carbon graphite and copper alloys, which provide superior strength, hardness, and wear resistance. This makes them ideal for high-temperature and high-load applications.

Graphite copper bushings can withstand high temperatures and are resistant to corrosion, making them suitable for use in harsh environments such as marine applications and industrial machinery.

Reduce downtime, increase self-lubricating bearing service life & save cost for moving applications. Get Your Instant Quote

Scientific American is part of Springer Nature, which owns or has commercial relations with thousands of scientific publications (many of them can be found at www.springernature.com/us). Scientific American maintains a strict policy of editorial independence in reporting developments in science to our readers.

Graphite bush bearings are self-lubricating bearings crafted from carbon graphite materials, combining the lubricity of graphite with the durability of metal. This makes them exceptionally well-suited for scenarios where traditional lubricants are impractical. Here are some essential insights into graphite bush bearings:

Material Variants: Beyond pure graphite bushings, we also offer graphite-impregnated brass bushings, which leverage the combined benefits of graphite’s lubricity and brass’s mechanical strength.

We offer CuSn8 solid bronze wrapped sliding bearings. Customized parts with seals or graphite are available upon request.

Product Details. Catalogue Number: 100-26. Description: Recombinant Human FGF-10. FGF-10 is a heparin-binding growth factor that belongs to the FGF family ...

Another reason wind experts say bigger is better: longer turbine blades also catch the wind more efficiently, and taller towers enable lengthier blades. A turbine’s power is directly related to its “swept area”—the circular area covered by the blades’ rotation—explains Christopher Niezrecki, a professor of mechanical engineering and director of the Center for Wind Energy at the University of Massachusetts Lowell. And this relationship is not linear—if blade length doubles, a system can produce four times as much energy, Niezrecki explains. He notes that bigger turbines also have a lower “cut-in” speed, the wind speed at which they can start generating energy.

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Tailored design and guidance for bearing bushing materials, including selection guides for sliding materials and bushing types.

Annie Sneed is a science journalist who has written for the New York Times, Wired, Public Radio International and Fast Company.

Do you require specialized custom products or are you in search of bearings for unique requirements? No problem: We fabricate and deliver custom plain bearing variants beyond standard dimensions, including special parts—all according to your specifications or technical drawings!

Jun 26, 2022 — 1 wheel bearing should be about $350 to replace for a shop. Run from that shop.

Turbines are already noticeably larger than they were 15 or 20 years ago. Size varies, but today’s typical wind farm towers stand around 70 meters tall, with blades about 50 meters long. Their power output depends on size and height, but it generally ranges between one and five megawatts—on the upper end, that’s enough to power about 1,100 homes. “There's this motivation to go to larger wind turbines, and the reason is pretty much economics,” explains John Hall, an assistant professor of mechanical and aerospace engineering at the University at Buffalo, S.U.N.Y. One reason giant turbines are more cost-effective is that wind blows stronger and more steadily at greater altitudes. Thus, “you capture more energy” with a taller structure, says Eric Loth, project leader of the massive turbine project, which is funded by the U.S. Department of Energy’s Advanced Research Projects Agency–Energy (ARPA–E).

Graphite copper bushings offer a reliable, maintenance-free solution for a wide range of industrial applications. Their combination of self-lubrication, high load capacity, and durability makes them an excellent choice for environments where traditional lubricants are impractical or where maintenance is challenging. Whether in heavy machinery, marine applications, or high-temperature industrial equipment, these bushings provide enhanced performance and longevity.

Material Strength: Made from carbon graphite, these bearings offer superior strength, hardness, and wear resistance, enhancing their longevity and performance.

Compare Urethane with Metal, Plastic, and Rubber -- take a look at the various advantages of polyurethane over other materials.

Customization: We provide custom manufacturing services for graphite bush bearings, accommodating a variety of sizes, shapes, and quantities to meet specific requirements.

Graphite copper bushings are embedded with graphite or other solid lubricants, allowing them to self-lubricate. This eliminates the need for external lubrication, which is particularly beneficial in environments where applying lubricants is challenging or impractical.

Den omtrentlige pakkestørrelse eller størrelsen på produktets pakke er 255 x 509 x 509 mm. Engine Chevy LS Vægt 14,6 kg(Produktet kan have let salgspakning ...

Loth and his team have yet to test a prototype; they are currently designing the turbine’s structure and control system, and this summer they are building a model much smaller than the real thing—about two meters in diameter. Next summer they plan to construct a larger version with two 20-meter-long blades, which will produce less than a megawatt of power and will be tested in Colorado. Loth himself is not 100 percent certain his team’s mammoth turbine will become a reality but he is sure it is worth trying. “This is a very new concept, so [there are] definitely no guarantees it will work,” he says. “But if it does, it will revolutionize offshore wind energy.”

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

The following is a list of models, specifications, and sizes of self-lubricating graphite copper bushing commonly used without a stop (tick “√” indicates the size and model of this specification) :

Diverse Options: Available in multiple sizes and configurations, including radial, thrust, and sleeve bearings, our graphite bush bearings are designed to meet various application demand

What does LGMT stand for? · LGMT — Mytilene International, Mytilene, Greece · LGMT — Mytilene (Mytilini)-Lesbos, S-Greece.

If you're enjoying this article, consider supporting our award-winning journalism by subscribing. By purchasing a subscription you are helping to ensure the future of impactful stories about the discoveries and ideas shaping our world today.

The self-lubricating nature of graphite copper bushings means they require no maintenance, reducing downtime and operational costs. This feature is especially advantageous in applications where regular maintenance is difficult or impossible.

We produce bronze alloys in compliance with global standards. Get in touch with us. Available in various grades, they meet stringent international standards.

The 500-meterturbine still faces challenges—there are good reasons no one has yet built one close to this size: “How do you make 200-meter blades? How do you put them together? How do you erect such a tall tower? Cranes only go so high. And with offshore wind, [there are] additional complications,” Niezrecki says. The team’s design includes a segmented blade that could be assembled from pieces on site, but Niezrecki notes the wind industry has not quite figured out how to segment the blades just yet. “There are lots of research questions to be addressed,” he says. “It’s definitely high risk, but there’s also potential for high reward as well. I don’t think those problems are insurmountable.” Hall also questions whether such a massive turbine is the optimal size. “We are figuring out that bigger is better. The question is, how much bigger? We need to find that sweet spot,” he says. “We’re going to learn a lot from this project.”

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

High Load Capacity: These bearings are capable of supporting high loads, making them a robust choice for high-temperature applications.

In the team’s design the two blades are located downwind of the turbine’s tower, rather than upwind as they are on traditional turbines. The blades also change shape with the wind’s direction, similar to a palm tree. “When the blades bend back at a downwind angle, you don’t need to build them as heavy or strong, so you can use less material,” Loth explains. This design also lessens the possibility that strong winds will bend a spinning blade toward its tower, potentially knocking the whole structure down [Video]. “The blades will adapt to high speeds and start to fold in, so there are less dynamic forces on them,” Loth says. “We’d like our turbines to be able to handle higher than 253-kilometer-per-hour winds” in nonoperating conditions.Above a wind speed of 80 to 95 kilometers per hour the system would shut down and the blades would bend away from the wind, so they could withstand violent gusts, Loth adds.

Graphite copper bushings are available in various sizes and configurations, including flanged, cylindrical, and thrust bearings. They can be customized to meet specific requirements, making them suitable for a wide range of applications, from heavy machinery to high-temperature environments.

Wind energy is soaring in the U.S.; the nation’s renewable energy capacity has more than tripled in the past nine years, and wind and solar power are largely responsible. Now businesses want to harness even more wind energy, at a cheaper price—and one of the best ways to lower cost is to build bigger turbines. That’s why an alliance of six institutions led by researchers at the University of Virginia are designing the world’s largest wind turbine at 500 meters tall—almost a third of a mile high, and about 57 meters taller than the Empire State Building.

Graphite copper bushings, also known as graphite copper bearings, are self-lubricating components that combine the lubricity of graphite with the durability of metal, typically copper or bronze alloys. These bushings are designed to provide maintenance-free operation, high load capacity, and excellent wear resistance, making them suitable for various industrial applications.

Self-Lubrication: Graphite bush bearings naturally lubricate themselves, eliminating the need for external lubrication. This feature is particularly beneficial in environments where applying lubricants is challenging.

Shop a large range of flanged bearing bushings – maintenance-free self-lubricating slide bearings with dry lubricating pins at bronzelube.com. Support all your metal copper bushing and maintenance repair needs … with excellent quality, to win customers of all ages.

Nov 29, 2021 — Wheel off the ground, grab tire at top and bottom, shake vigorously and check for play. Only works on a very bad bearing.

17618-Tapovan Express , departs usually from HUZUR SAHIB NANDED at 10:05. It takes almost 12hr 3 min for the journey as per the train time-table.

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Oct 20, 2021 — How to Replace a Timing Belt? · Step 1: Get The Correct Replacement Timing Belt · Step 2: Gaskets · Step 3: Disconnect The Battery · Step 4: ...

Versatile Designs: Our offerings include both standard and custom-designed graphite and tin bronze bushings and bearings, tailored to diverse industrial needs.

The team also envisions these gigantic structures standing at least80 kilometers offshore, where winds tend to be stronger and where people on land cannot see or hear them, according to Loth. But powerful storms hit such places—off the U.S. east coast in the Atlantic Ocean, for example—so Loth’s team faced the quandary of creating something massive that is also relatively lightweight and still resilient in the face of hurricanes. To tackle the problem, the researchers looked to one of nature’s own design solutions: palm trees. “Palm trees are really tall but very lightweight structurally, and if the wind blows hard, the trunk can bend,” Loth says. “We’re trying to use the same concept—to design our wind turbines to have some flexibility, to bend and adapt to the flow.”

Solid brass bushings available in various bronze alloys including CuSn7ZnPb (RG7), CuSn10, CuSn12, CuPb10Sn, CuPb15Sn, CuAl10Ni, CuSn10Zn (RG10), CuZn25Al5, CuSn5ZnPb (RG 5), featuring lubrication groove designs.

Loth’s team wants to design a 50-megawatt system with blades 200 meters long, much larger than today’s wind turbines. If the researchers succeed, they believe the turbine would be 10 times more powerful than existing equipment. But the scientists do not intend to simply supersize conventional designs; they are fundamentally changing the turbine structure. The ultralarge machine will have two blades instead of the usual three, lowering the weight of the structure and cutting costs.Loth says that reducing the number of blades would ordinarily make a turbine less efficient, but his team is using an advanced aerodynamic design that he says largely makes up for those losses.

Choose from our selection of mounted ball bearings, mounted bearings, bearing housings, and more. In stock and ready to ship.

Broad Applications: Graphite bush bearings are versatile and used in a range of applications, including those in submerged and high-temperature environments.

Oilless Bearing Oilless Brass Flange Bushing Graphite Plugged Bearing. Graphite Bushings And Bearings – Reduced Costs & Downtime

8613869596835

8613869596835