Mityvac Brake Bleeder Adapter Kit - 822664, Tools - brake bleeder adapter kit

Rubber sealvsmetal sealbearing

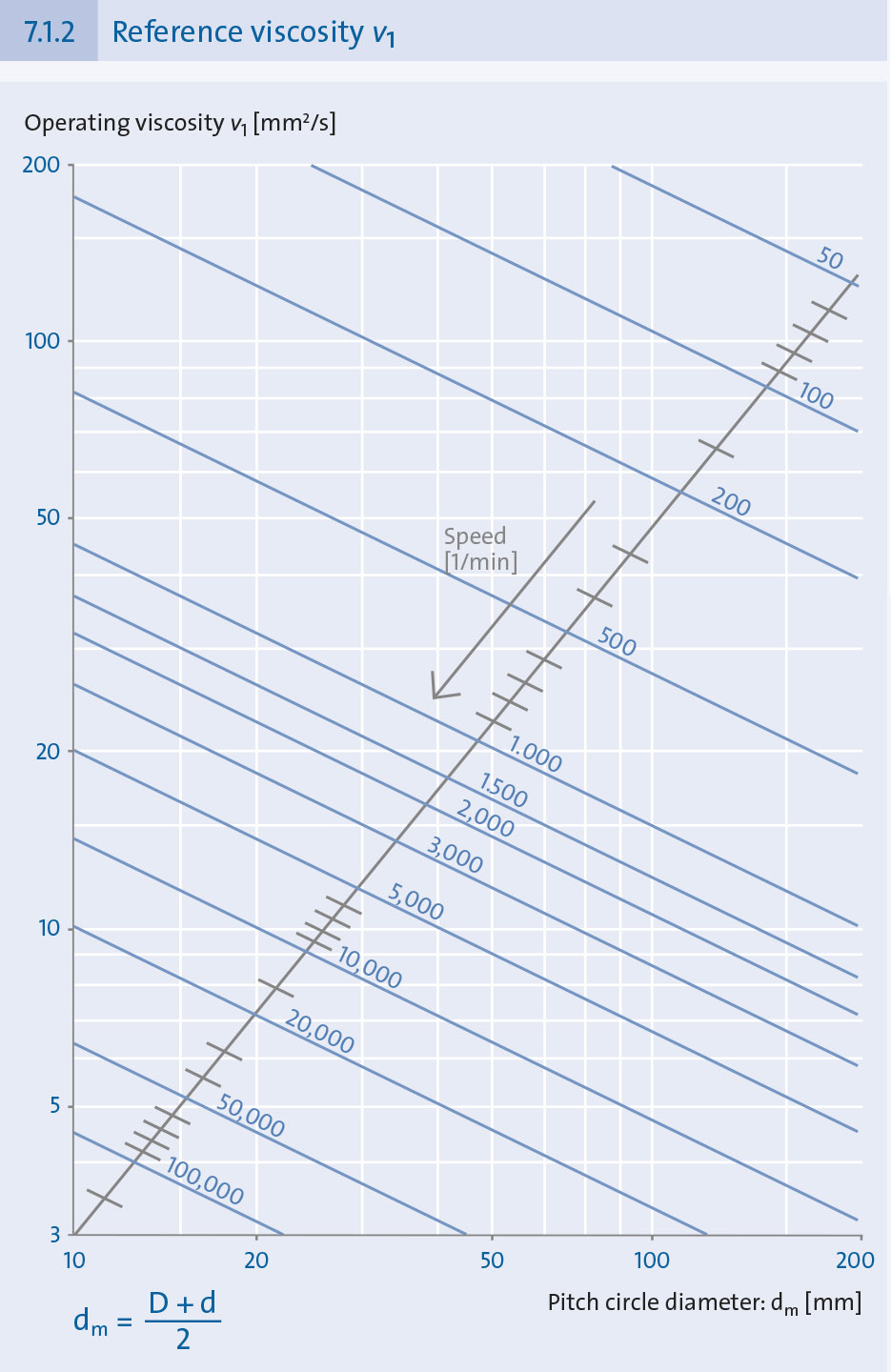

Calculating life expectancy determines the bearing solution with consideration of bearing material fatigue under defined operating conditions. Calculation procedures as per DIN ISO 76 (static load rating) and DIN ISO 281 (dynamic load rating and life expectancy).

One of the main advantages of sealed bearings is their ability to provide superior protection against contaminants. This makes them well-suited for applications in industries such as agriculture, construction, and automotive, where bearings are exposed to harsh conditions. Sealed bearings also tend to have a longer lifespan and require less maintenance compared to shielded bearings.

Sealedbearingsvsgreasable bearings

In conclusion, the maximum speed of sealed bearings is generally lower than that of shielded bearings due to the added friction and resistance created by the seals. However, both types of bearings have their own advantages and disadvantages, and the choice between sealed bearings and shielded bearings should be based on the specific requirements of your application. By understanding the differences in maximum speed ratings of these two types of bearings, you can make an informed decision and ensure the reliable and efficient operation of your machinery and equipment.

Sealed bearing vsballbearing

For example, a typical sealed bearing may have a maximum speed rating of 12,000 RPM, while a shielded bearing of the same size and construction may have a maximum speed rating of 15,000 RPM. This difference in maximum speed can be significant in applications where high speeds are required, such as in motors, pumps, and compressors.

Greasingshieldedbearings

It is important to note that the maximum speed ratings of bearings are just guidelines, and the actual operating speed of a bearing may be lower depending on factors such as the load, lubrication, and operating conditions. It is always recommended to consult with the bearing manufacturer or a qualified engineer to determine the appropriate bearing for your specific application and operating conditions.

On the other hand, shielded bearings are bearings that have metal shields on one or both sides of the bearing. These shields provide some protection against contaminants, but they are not as effective as seals in preventing the ingress of dust, dirt, and moisture. Shielded bearings are commonly used in applications where the risk of contamination is lower, such as in machinery and equipment that operates in clean environments.

One of the key differences between sealed bearings and shielded bearings is their maximum speed ratings. The maximum speed of a bearing is the highest speed at which the bearing can operate without experiencing premature failure or damage. This speed is typically specified by the bearing manufacturer and is influenced by factors such as the type of lubrication used, the material of the bearing, and the design of the bearing.

Shielded bearings, on the other hand, are bearings that have metal shields or plates that cover the bearing’s open sides. While shielded bearings provide some protection against contaminants, they are not completely sealed like sealed bearings. This means that shielded bearings are not as effective at keeping out dust, dirt, and moisture.

Globus, GMN’s ball bearing calculation program, allows for computer-aided calculation and the selection from a broad product range in consideration of the life expectancy of various possible solutions.

When it comes to bearings, there are two main types that are commonly used in various applications: sealed bearings and shielded bearings. While both types serve the same purpose of reducing friction and allowing for smooth rotation, there are some key differences between the two that should be considered when choosing the right type for a specific application.

Shielded vsOpen bearings

Sealed bearings, are bearings that have a seal or a rubber shield on one or both sides of the bearing. This seal helps to keep out contaminants such as dust, dirt, and moisture, which can extend the life of the bearing and prevent premature failure. Sealed bearings are commonly used in applications where cleanliness and protection from external elements are important, such as in food processing equipment, medical devices, and automotive applications.

Sealed bearings are bearings that are completely enclosed and sealed with rubber or metal seals. This provides a high level of protection against contaminants such as dust, dirt, and moisture, making them ideal for applications where the bearings are exposed to harsh environments or contaminants. The seals also help to retain lubrication within the bearing, extending its lifespan and reducing the need for maintenance.

One of the main advantages of shielded bearings is their lower friction and heat generation compared to sealed bearings. This allows for smoother operation and increased efficiency, making shielded bearings ideal for applications that require high speeds or low torque. Shielded bearings also tend to be more cost-effective compared to sealed bearings.

One can determine bearing vibrations on the basis of structural sound level tests which allow to make conclusions about surface quality (waviness) in the bearing rings and balls. Low structural sounds are the result of high smoothness as well as low friction, and predict high performance and long life expectancy of the bearing.

Doshieldedbearings need to be greased

Doubleshielded bearing

In general, sealed bearings have lower maximum speed ratings compared to shielded bearings. This is because the seals on sealed bearings create more friction and resistance, which can limit the speed at which the bearing can operate. On the other hand, shielded bearings have less resistance and therefore can operate at higher speeds.

However, the lack of complete sealing in shielded bearings means that they are more susceptible to contamination. This can lead to premature wear and reduced lifespan, especially in applications where the bearings are exposed to harsh conditions. Shielded bearings also require more frequent maintenance and re-lubrication compared to sealed bearings.

Openbearing vs sealed bearing

Design and geometry of the individual parts, as well as the design of the entire bearing define bearing frequencies. The characteristic structural sound level of a ball bearing is composed of the sum of all bearing frequencies.

However, sealed bearings do have some drawbacks. The seals can create additional friction, which can lead to increased heat generation and reduced efficiency. Sealed bearings may also have limited options for lubrication, as the seals can prevent easy access to the bearing for maintenance or re-lubrication. Additionally, sealed bearings tend to be more expensive than shielded bearings.

When selecting the right bearing for your application, one of the key factors to consider is the bearing's maximum operating speed. Two types of bearings commonly used in various industrial applications are sealed bearings and shielded bearings, both of which have their own advantages and disadvantages.

8613869596835

8613869596835