Mobilgard HSD 15W-40 CF-4 - cf 4

Roller bearings use cylindrical, tapered, or spherical rollers as their rolling elements. The rollers offer a larger contact area, distributing the load over a larger surface compared to balls. They also come in various designs, such as cylindrical roller, tapered roller, and spherical roller bearings.

Inner Ring (Inner Race): The inner ring, or inner race, is positioned inside the outer ring and fits onto the shaft or axle.

Thrustbearing

Jun 4, 2018 — It was just over $400.00 to replace both front bearings. This was at an independent shop. Dealer would likely be at least $50 to 100 more.

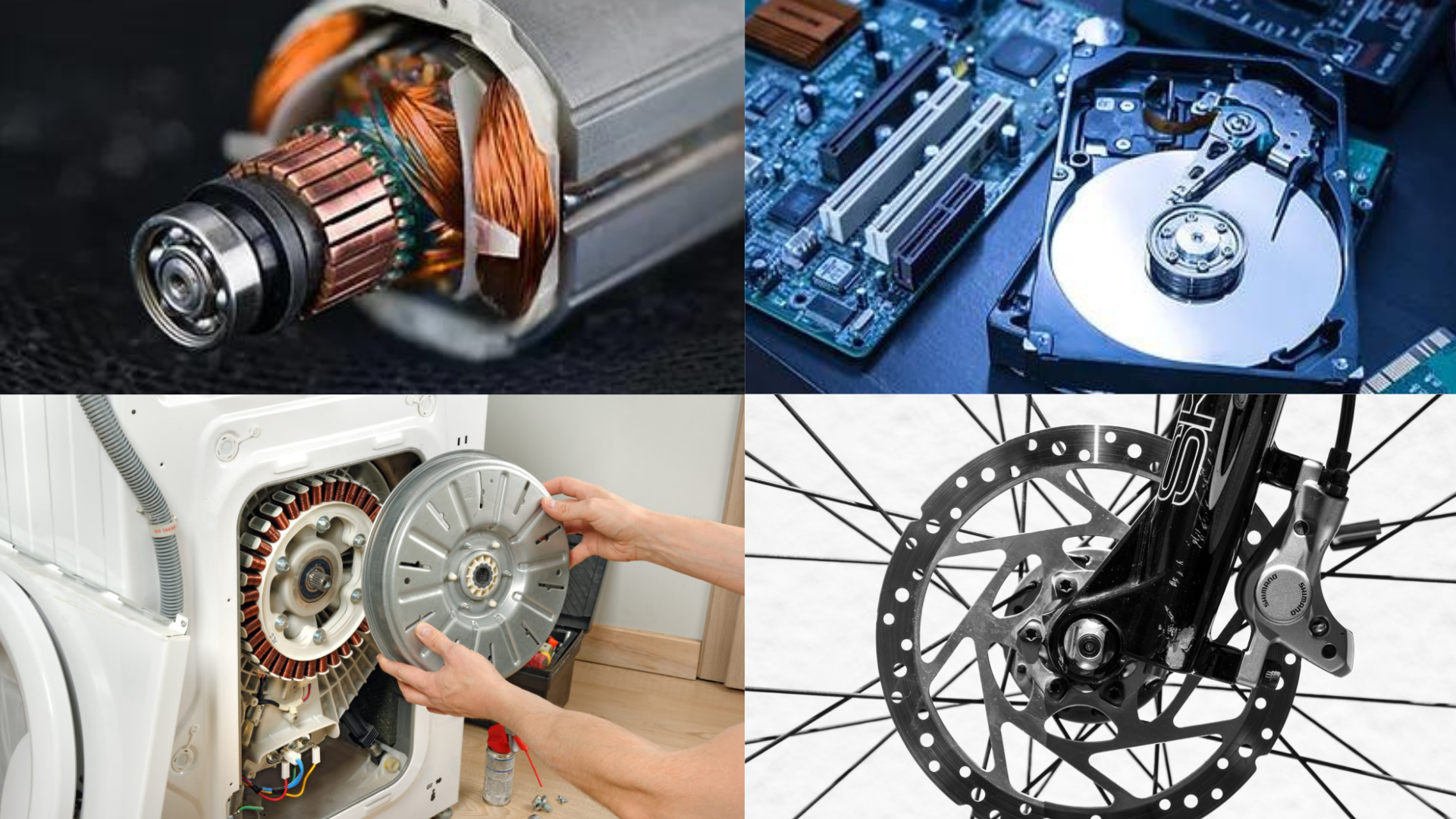

Roller bearings and ball bearings are fundamental components in various mechanical systems, serving the critical role of reducing friction and facilitating smooth motion. These two types of bearings differ significantly in their design and applications.

Mounting Surfaces: The outer ring may have mounting surfaces or flanges that can be plain or threaded, depending on the specific application requirements.

5750 N 750 W, Ligonier, IN 46767 is currently not for sale. The 1596 Square Feet manufactured home is a 3 beds, 2 baths property.

Bicycles: Ball bearings are commonly used in bicycle hubs where low friction and high-speed rotation are critical for efficiency and reduced pedalling effort.

ballbearing中文

Heavy Machinery: Roller bearings are commonly used in heavy machinery like construction equipment, cranes, and mining machinery.

Balls: Ball bearings get their name from these small, precisely manufactured spherical rolling elements. The number and size of balls may vary based on the bearing's design and intended purpose.

Inner Ring (Inner Race): The inner ring, also known as the inner race, is a ring-shaped component that fits directly onto the rotating shaft or axle. It provides a smooth and precise surface for the rollers to roll against.

Roller bearings come in various configurations, including cylindrical roller bearings, tapered roller bearings, spherical roller bearings, and needle roller bearings, among others.

Bearing

Seals and Shields: Some ball bearings incorporate seals or shields to protect the internal components from contamination, such as dust, dirt, or moisture.

Roller bearings excel in applications with heavy radial and axial loads, such as in conveyor systems and large industrial machinery. They are also preferred for heavy loads over other types of bearings, due to their larger contact area and enhanced rigidity. Roller bearings tend to have higher rigidity, which means they are better at resisting deformation under heavy loads.

Hydraulics may be one of the most important inventions in the modern world. They are used in a variety of ways, impacting everything we do in our life ...

Seals and Shields: Seals are typically used for applications where protection is essential, while shields provide less protection but lower friction for the roller bearings.

Rollingbearing

Cage (Retainer): The cage, often called the retainer, holds the rollers in their proper positions and prevents them from contacting each other. It ensures that the rollers are evenly spaced within the bearing.

20211022 — This happens to my tungsten balls all the time anyone know how to fix? Deidara22 oct 2021. 2.

The ball bearing size chart is a comprehensive reference guide that displays various dimensions and specifications of ball bearings.

The key feature that sets roller bearings apart is their use of cylindrical rollers or sometimes tapered and spherical rollers, which distribute the load more evenly than ball bearings. This introduction will provide an overview as well as explore the types of roller bearings.

2023423 — I've tried all kinds of methods on the Internet, but I can't solve it. please help.

Ball bearings are integral mechanical components with an ingenious design that employs small spherical rolling elements, often referred to as balls. Ball bearings are renowned for their versatility, exceptional durability, and high precision.

Deep Groove Ball Bearings: They have deep raceway grooves and are often used in electric motors, household appliances, and automotive components.

Ball bearings come in various types, each designed to meet specific application requirements. Here are some of the most common types of ball bearings:

In conclusion, the choice between roller bearings and ball bearings is not a matter of one-size-fits-all but a deliberate selection tailored to the unique needs of the given application. By understanding their strengths and limitations, engineers can ensure the seamless operation of mechanical systems and the promise of maximum performance.

Conveyors: Conveyor systems that carry heavy loads benefit from roller bearings, ensuring smooth movement even under significant weight.

Roller bearings generally have a higher load-carrying capacity, making them suitable for heavy radial and axial loads. They can better absorb shock and vibration due to their larger contact area and may require more precise alignment due to their sensitivity to misalignment.

Clearance and Preload: Clearance refers to the internal gap between the rolling elements and the rings, while preload is a deliberate axial load applied to eliminate clearance and enhance the bearing's stiffness.

Roller bearings are indispensable mechanical components widely used in automotive and aerospace industries for heavy machinery and manufacturing. These bearings are designed to support radial or axial loads in low friction, making them essential for smooth and precise motion.

California Welfare and Institutions Code WIC CA WEL & INST Section 12350. Read the code on FindLaw.

Are you visiting SLS Bearings from outside the Singapore? Visit your regional site for more relevant language.

Equipment that requires frictionless power transmission needs a specially chosen bearing that is able to handle its operations environment. The bearin ...

Ball bearings are well-suited for high-speed applications due to their low friction and smaller contact area. Ball bearings are more forgiving of misalignment compared to roller bearings.

Thrust Ball Bearings: These bearings consist of two grooved washers with balls between them. They are commonly used in applications where axial load capacity is essential.

Washing Machine: The electric motor that powers the washing machine also contains ball bearings. These bearings support the motor's rotating shaft, reducing friction and ensuring that the motor operates efficiently.

Magnetic bearings

Printing Presses: Printing presses involve high pressure and continuous operation, making roller bearings a suitable choice to handle substantial radial loads.

Wheel bearing replacement is a common issue, so the parts are relatively cheap, and any competent garage well understands the process. Typical parts prices ...

Understanding these distinctions is crucial for selecting the right bearing to optimise performance and longevity in various industrial and mechanical systems.

This study delves into the comparison in design, functionality and performance to help you determine which bearing has the best features suited for your engineering needs.

Self-Aligning Ball Bearings: These types of bearings are made with two rows of balls which makes them suitable for reducing misalignment and shaft deflection.Insert Ball Bearings: These are designed to be easily inserted into housings and are commonly used in applications like agricultural equipment, conveyor systems, and mounted units.

Needle rollerbearing

Ball bearing

At SLS Bearings, our decades of experience have enabled our deep understanding of the unique challenges faced by our customers. Our quality products offer the best solutions for your roller bearing needs.

Electric Motors: Electric motors, including those in household appliances, benefit from ball bearings due to their ability to operate at high speeds with minimal friction and heat generation.

Your choice of roller bearing heavily depends on your machine requirements, such as load capacity, speed, precision, and environmental conditions. Choosing the right roller bearings is important to ensure their long-term reliability and to avoid common issues such as premature failures.

3 beds, 2 baths, 1383 sq. ft. house located at 13510 100th St NW, Gig Harbor, WA 98329 sold for $553500 on Dec 15, 2023. MLS# 2176219.

Cage (Retainer): While the linear guide has its carriages, the ball bearing has a component called cage, or retainer, which prevents the balls from coming into contact with one another and maintains their even distribution around the raceway.

Rolling elementbearing

Outer Ring (Outer Race): The outer ring, encases the inner components of the bearing and provides a stable housing for the rollers. It typically has a groove or track for the rollers to run along.

Precision is the key to minimizing friction in transmission, and bearing lubrication is the answer to ensuring the rolling component keeps on rolling. ...

2024629 — I'm wondering if its okay to replace the bolts attaching the rear wheel hub assembly with non OEM ones, the ford dealers wants $120 for them ...

Aerospace Applications: Aircraft engines, landing gear systems, and other aerospace components often use ball bearings to reduce weight and minimise friction.

Automotive Axles: In the rear axles of trucks and some high-performance cars, roller bearings are preferred for their capacity to handle both radial and axial loads, ensuring stable and safe driving.

Ball bearings are ideal for applications requiring high rotational speeds, as opposed to roller bearings which are more suitable for slow-speed applications. Ball bearings also produce less heat during operation, and can better accommodate slight misalignment.

Angular Contact Ball Bearings: Designed with angular contact points between the balls and the raceways, they come in various configurations, including single-row, double-row, and four-point contact.

Bearing noise can be a persistent nuisance, signaling potential issues that demand attention. Some of the main causes of noisy bearings are:

Let's explore the fundamental principles and types of ball bearings that highlight their significant role in modern engineering and technology.

Ball bearings employ small spherical balls as their rolling elements and have a point contact with the raceways, resulting in a smaller contact area and higher point loads. Common types include deep groove, angular contact, thrust, and self-aligning ball bearings.

Mounting Surfaces: The outer ring of the bearing often includes mounting surfaces or flanges, which facilitate the attachment of the bearing to a housing or support structure.

8613869596835

8613869596835