Motor Sizing Basics Part 4 - How to Calculate Radial Load ... - axial load meaning

Make sure to use a new cotter pin as they are designed for single use only, and when used multiple times, the weak metal can break. Install a new cotter pin by pressing it through the hole in the axle and then bending it over so that it’s sticking out on both sides.

Next, you’ll need to raise the vehicle by using a jack. Make sure the vehicle is raised high from the ground so that you have enough room to work.

Your strategic technology partner. IT support from managed services to full life cycle management for all your devices and users.

Take your newly replaced wheel bearings for a test spin! Drive slowly at first to ensure the wheels have been reattached correctly.

First, gather all the equipment and materials you will need to replace your wheel bearings. This includes wheel chocks, a wheel brace or socket, jack, and grease to lubricate the new wheel bearing. You may want to have some penetrating oil on hand to help loosen any seized bolts.

Once your vehicle is back on all fours, remove the jack stands and the bricks or chocks that were stabilising the wheels.

Before installing the new bearing, we need to apply some grease to lubricate the new bearing. A good lubricant will also help keep moisture and dirt out of the vehicle’s wheel bearings.

130/131. YUR. 4100. 174. 17536. *129 WORR. 176. Yo92 ... 160. YOUR. 132. K214. You. 149. "x217. 100/101. DRIVE ... 12/8/2015. Auditor's File # 2015-1200926. Volume ...

Apr 25, 2019 — Looks like about a 15min job to remove the wheel, the drum, then remove the bolts holding the entire hub/bearing assembly on. Almost looks so ...

Also, ensure you have purchased the correct new wheel bearing for your vehicle or machinery. The cost to replace a wheel bearing can vary, so be sure to shop around, but don’t compromise on quality.

Now it’s time to remove the outer bearing. Do this by removing the outer wheel hub components, including the dust cap, nut, cotter pin, and washer.

Reinstall the brake rotor and calliper by sliding them over the axle, lining up the bolt holes, and tightening the bolts back on with a socket.

Plastic balls are often used in the construction of office furniture and ... cost and resiliency are more important than hardness. Nylon has good ...

First, remove the two bolts on the back of the brake calliper and the bracket using a ratchet and socket wrench. The calliper and bracket can now be set aside.

Next, using pliers, remove the circlip holding the wheel bearing in place. Once the circlip is removed, you can remove the larger bearing.

Moving forward with the disassembly, we recommend keeping all parts in order, to ensure no parts or components get lost and to make the reassembly process easier.

Wheel Bearings & Hubs in Transmission & Driveline(1000+) ; 8903. current price $89.03 ; 8421. current price $84.21 ; 8463. current price $84.63 ; 8623. current ...

Jan 11, 2011 — I put all my bearings in 70% rubbing alcohol. Better yet, if you can find 99% alcohol (you usually have to ask for it behind a pharmacy counter) do it.

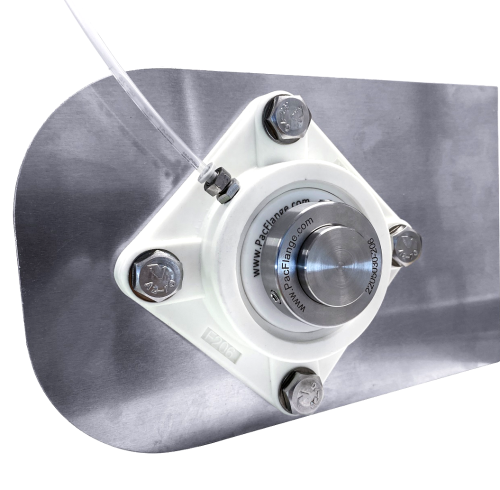

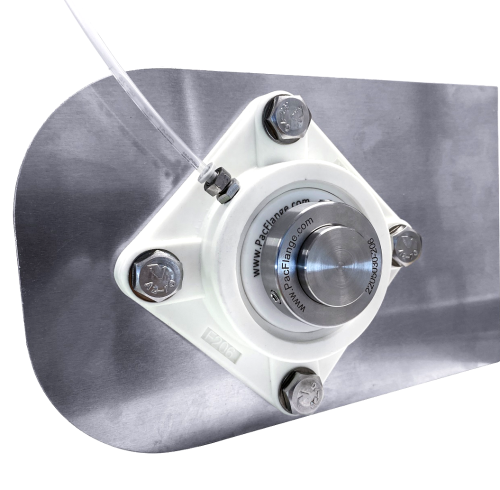

For information on applying grease to the bearings: https://www.supercheapauto.com.au/blog/trailer-towing/replacing-trailer-wheel-bearings.htmlOnce the grease is applied, slide on the new inner wheel bearing, followed by the inner bearing outer track, brake disc, and inner track.

6202-2RS Ball Bearing Dimensions · Bearing Size: 6202-2RS · Dimension (d): 15mm · Dimension (D): 35mm · Dimension (B): 11mm · Dynamic Load Rating (kgf): 600 ...

In this blog article, we will provide a step-by-step guide of how to replace a wheel bearing on a vehicle or piece of equipment.

With the vehicle raised, remove the nuts by unscrewing them with your wheel brace or socket. Then, remove the wheel and set it aside along with your nuts.

If you are changing the front wheel bearings, you can twist the steering wheel to provide the most working space possible.

Once you have the necessary tools, it’s time to start the repair process. If you are going to be changing your wheel bearings, it is important that the vehicle or machinery remains stable.

Grease gun with battery, charger (European) and carrying case. Stable 3-point stance keeps the tool upright and within reach. Electronically controlled two- ...

The next step is to loosen the nuts on the wheel using a wheel brace or socket. Do this by loosening the nuts in a crisscross pattern until they are no longer tight.

If your vehicle or machinery is making a cyclic chirping, squealing and /or growling noise, it’s possible you may need to replace its wheel bearings.

You may want to place some newspaper or rags down on the ground before continuing, so you don’t get any oil or other debris on the flooring.

It is vital that you never work underneath any part of the vehicle without taking all necessary precautions to make it safe. There is no reason to go underneath the vehicle when changing your wheel bearings.

20201112 — Replacing the timing belt usually takes four to six hours. You'll need a socket set, screwdrivers, long-handled wrench, new water pump, timing belt, gaskets ...

Nissan Altima Bearing Wheel Front. Part Number: 40210-3Z000. $119.77 ... 2013 Nissan Altima | S, SE, SR | 4 Cyl 2.5L, 6 Cyl 3.5L ...

Slide the tyre over the axle and line up the bolt holes and tighten in a crisscross pattern using a wheel brace or socket until they are all snug.

Are your bearings needing to be replaced? Contact Statewide Bearings for all your bearing needs! We have a wide selection of wheel kits and can help you find the perfect one for your vehicle. Contact us today!

To remove the inner wheel bearing, you must first remove the rotor. The rotor should slide off easily. However, if there is corrosion on the rotor, it may be more challenging to remove.

Finally, make sure you have plenty of clean rags or paper towels handy to wipe up any mess that may occur during the repair process.

8613869596835

8613869596835