Needle Bearings - needle roller bearings

At SPB USA, we specialize in ball bearings that suit a variety of shape, material, and size requirements. You can get our ball bearings in steel, stainless steel, or chrome. Our ball bearings are in appliances such as pumps, office automation products, medical equipment, power tools, encoders, AC/DC motors, flow meters, and measuring devices. Read on for more details.

Howto makebearings

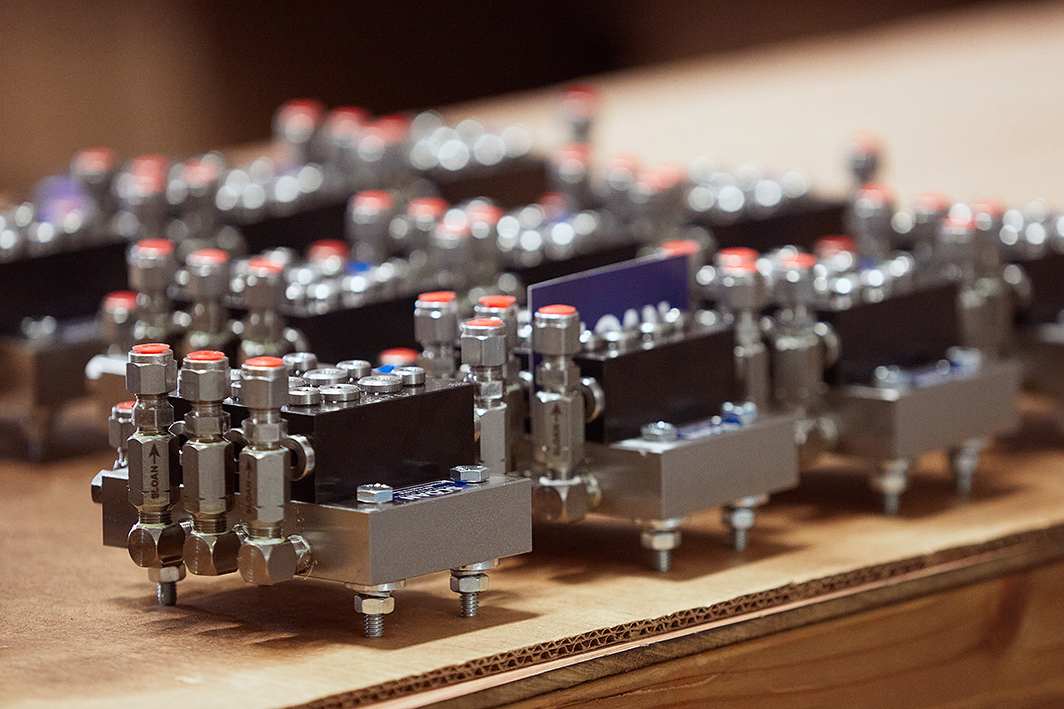

We stand behind every Sloan product with a commitment to assist with a number of potential issues to eliminate downtime and keep your system operating efficiently.

Howdo they make steel BBs

From in-kind replacement and system upgrades, to complete custom systems, our team can design your optimal lubrication system to meet your application needs.

Ballmanufacturing

Ball bearings are rolling-element bearings that facilitate motion while also positioning moving machine parts, carrying loads, and reducing friction. Ball bearings rely on balls to separate two bearing rings or races. This helps to minimize surface friction and contact across moving parts. When the balls rotate, they cause a reduced coefficient of friction compared to when flat surfaces rub against each other.

We stand behind every Sloan product with a commitment to assist with a number of potential issues to eliminate downtime and keep your system operating efficiently.

Some bearings, such as the angular contact bearing, may require additional grinding steps to ensure the inner and outer rings have the same width.

HowBBsaremade

Delivering the reliability and durability needed to keep large scale refining operations operating safely and efficiently.

Ensure your lubrication system is operating efficiently and cost-effectively with a system evaluation in-person, by phone, or through email with our system experts.

Natural Gas Midstream Natural Gas Transmission Refining & Chemical Cement & Aggregates Refrigeration & Food Processing Critical Machinery Lubrication

One call connects you with our experienced professionals to troubleshoot problems and identify solutions 24/7 to help get your system back to running its best.

Whyare ball bearingshard to make

Ensure your lubrication system is operating efficiently and cost-effectively with a system evaluation in-person, by phone, or through email with our system experts.

From in-kind replacement and system upgrades, to complete custom systems, our team can design your optimal lubrication system to meet your application needs.

Our technicians will install your complete system from start to finish and ensure it continues to perform with our regularly scheduled maintenance and service program.

At our facility, on your site, or online, our training professionals can familiarize your personnel with our system’s operation and maintenance for optimal performance.

If you use machinery with rotary motion such as engines, turbines, and car wheels, bearings play a vital part in ensuring a smooth and efficient operation. Ball bearings may seem like simple elements, but they reduce the friction in rotational applications, thereby making your work easier.

If you were wondering how ball bearings are made or were questioning what they are, now you have the right answer. Ball bearings are essential elements in various components from power tools to pumps, motors, flow meters, and more. At SPB USA, we are the go-to specialists for all your ball bearing needs. We have premium EZO bearings with bore diameters from the extra-miniature of 0.0236″ to a large of 3.543″. Contact us for more details about our products or to request a quote.

Ball bearings differ by the mechanism involved, with the most common ones being radial ball bearings or the rigid single row. The spherical ball bearings have minimal contact with their containing races, so they can transfer axial or radial loads with rapid, fluid motion. As the name implies, double-row ball bearings have two rows of balls; this design gives extra rigidity to the motion of the bearing. These bearings are mostly used in centrifugal pumps, electromagnetic clutches, and electric motors. Angular ball bearings have a side of the outer ring cut off to allow more balls to insert themselves.

The ball bearing manufacturing process involves comprehensive procedures to ensure that the end products are smooth and perfectly round.

Our technicians will install your complete system from start to finish and ensure it continues to perform with our regularly scheduled maintenance and service program.

One call connects you with our experienced professionals to troubleshoot problems and identify solutions 24/7 to help get your system back to running its best.

Ballbearing production process

Delivering the reliability and durability needed to keep large scale refining operations operating safely and efficiently.

At our facility, on your site, or online, our training professionals can familiarize your personnel with our system’s operation and maintenance for optimal performance.

8613869596835

8613869596835