NY State Senate Bill 2025-S48 - s48

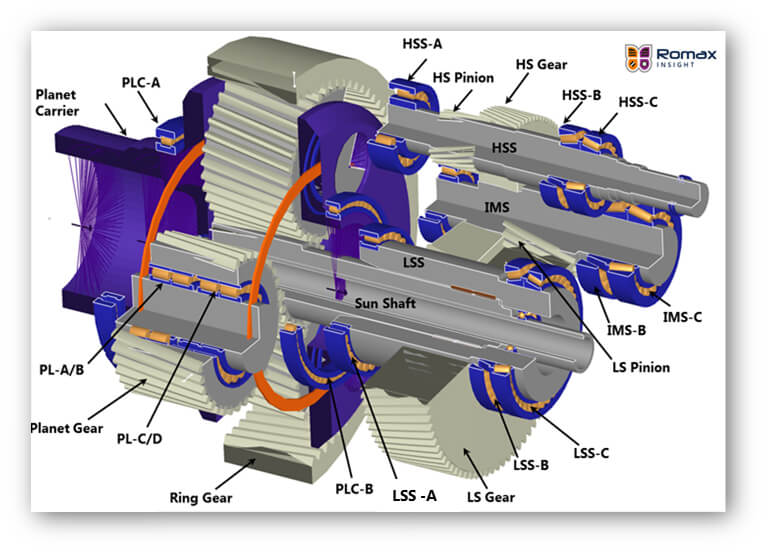

A typical wind-turbine contains 20 to 25 bearings, all of which must be considered in a system-level reliability calculation of life expectancy.

618AirPods Pro1899618146123% ...

The European Union Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU sets obligations for manufacturers of electrical and electronic equipment ( ...

Sixity Auto is also a leading auto parts retailer on eBay with over 99% positive feedback spanning 420,000+ feedback reviews!

Drivetrains, in particular, have had to change significantly to meet stronger, more variable wind loads and higher power levels — and without significant increases in costs. So, engineers took on the challenge and manufacturers delivered.

This is why the term “design life” is misleading, and one reason why many gearboxes in the field are failing in less than 20 years. One way to mitigate these failures is to employ more reliable engineering methods throughout the entire lifetime of a turbine. For example, using design standards and simulations, along with reliable operational data and historical failure rates, it is possible to provide accurate predictions of drivetrain failures.

We’re proud of our authorized seller status with dozens of global automotive aftermarket suppliers. This helps ensure that you get brand-new, quality auto parts and excellent service you’ve come to expect.

... 13954) PRODUCT AFFECTED: This issue affects Apache CXF. PROBLEM: By default, Apache CXF creates a /services page containing a listing of the available ...

For over 60 years, National has been a source of complete wheel end solutions that meet the needs of today’s vehicles. Trying to keep pace with the industry, the brand's Research and Development Center constantly explores new technologies and materials to use them in manufacturing only high-end, premium products such as National oil seals and National precision bearings. In its line of innovations, there is the Dynamic Edge seal design that includes an integral patent-pending sinusoidal wave allowing for maximum protection and preventing premature bearing damage.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Copyright © 2025 WTWH Media LLC. All Rights Reserved. The material on this site may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of WTWH Media Privacy Policy | Advertising

13144. The State Fire Marshal shall prepare in book or bulletin form excerpts of the laws, rules, and regulations dealing with fire and panic safety.

When you buy from an authorized seller like us, you get authentic parts from the manufacturer just as the manufacturer intended including original packaging, hardware, accessories, and instructions.

Did you know that National has been manufacturing complete wheel end solutions for over 60 years now? They've managed to keep pace with the industry over the years while producing superior products. Learn more about National here.

P2 designs, builds and delivers strategies and solutions which enable our customers to solve their most complex problems.

Shop with confidence, knowing that your purchase from Sixity Auto will fit your vehicle. If after purchase you determine that your part does not fit the vehicle we advertised, simply contact us to initiate a return. We want your parts to fit!

Don't take it from us - check out our feedback from our customers! Sixity Auto has partnered with Sitejabber, the industry leader in tracking customer loyalty and feedback, to bring genuine product and customer service reviews.

Wind turbinestructure

The life of a bearing is generally defined as the ‘L10’ life, which is the duration after which 10% of the bearings will fail. If L10 for one bearing is 20 years, then there is a 10% chance that the bearing will fail in less than 20 years. This is important because it forces manufacturers and wind operators to think about “lifetime” in terms of probabilities.

Get free shipping on qualified Bearing Replacement Engine Parts products or Buy Online Pick Up in Store today in the Outdoors Department.

At SixityAuto.com, we offer free shipping on all orders over $35! We not only ship free, we ship FAST. Over 99% of all items ordered will ship within one business day. Plus, we ship from our strategically located warehouses on the East and West Coast to save precious shipping time.

Shop by category: Deep groove ball bearing, Single row, With angular contact, With contact in 4 spot, Double row, Self aligning, double row, Linear Clutch ...

Based on this calculation, nearly all gearboxes in a wind farm are likely to fail within 20 years. This may seem shocking, but it is a reality in the field. Many wind operators will attest that most gearboxes have been changed or gone through an up-tower repair of some kind, such as a new high-speed stage shaft or bearings, long before its 20-year life is up.

What was once an off-the-shelf, industrial gearbox is now uniquely designed to meet the harsh conditions typical of a multi-megawatt turbine. A modern geared turbine typically has a 3-stage gearbox with a low-speed planetary stage and two parallel stages. By using planetary gears, designers created high-powered gearboxes that are durable enough to withstand harsh loading, yet compact enough to maintain a reasonable nacelle size.

Now let’s ask how many gearboxes will fail within seven years? The same calculation indicates that the probability of one or more bearings failing within seven years is 37%. This means more than one-third of gearboxes will suffer some sort of bearing failure.

ZFgearbox

We speak your language. Our staff has decades of experience selling auto parts to enthusiasts like you. Whether it's for your car, truck, or van, we have staff on hand that can answer your questions and make sure you get the part you're looking for.

Wheel bearings are situated between the rotating wheel and the stationary axle.Their job is to support the load, keep the wheel turning, and ...

It is also important to consider that a wind turbine has more than one bearing. A typical drivetrain has 20 to 25 bearings, including the main bearings, gearbox, and generator bearings. So, what happens if we combine the L10 life for every bearing in a drivetrain to calculate a “system-level life?” A simple calculation for a drivetrain with 25 bearings, all with an L10 design life of 20 years, indicates that the probability of one or more bearings failing within 20 years is 93%.

As utility-scale wind turbines have developed from the kilowatt-class to the multi-megawatt machines installed today, the components inside a nacelle have also evolved to keep up with new power demands.

Why the discrepancy? Part of the answer is in the way that gear and bearing lives are defined. The life of a gearbox component is stochastic, not deterministic. This means that it is impossible to predict with accuracy when a component will fail, even though it is possible to estimate the probability given certain parameters.

Not only that, but also buying authorized means that your auto parts are covered under the original manufacturer’s warranty, a benefit not available from unauthorized sellers.

These results come from a simplified calculation and are only intended to show overall trends, but they show some startling findings. Unfortunately, the calculation can under-estimate gearbox failure rates because it fails to account for non-fatigue failure modes. But the good news is that, in practice, some bearings offer a design life in excess of 20 years because their size is dictated by other factors, such as stiffness or safety factors during extreme load cases.

Mar 23, 2024 — Replacing a wheel bearing can cost anywhere between $100 and $300 for the parts alone. In some cases, you might need to replace the entire hub, ...

For phone sales or help with product fitment questions, our U.S.-based customer service staff in California and Indiana is available weekdays, 8am-8pm ET.

Browse the most current issue of Windpower Engineering & Development and back issues in an easy to use high quality format. Clip, share and download with the leading wind power engineering magazine today.

Appears the torque of the wind turbine blades exceed the durability of the bearings. Plus its a variable load too. I bet the North Dakota wind and temperature extremes increase the longevity of these high tech wind mills.

Description ... SKF Single row deep groove ball bearings are used in a wide variety of applications, they are simple in design, non-separable, suitable for high ...

Keep in mind that wind-turbine drivetrains undergo severe and variable transient loading during start-ups, shutdowns, emergency stops, and grid connections. A turbine’s loading depends on its location in the wind farm and the terrain. Load cases that result in torque reversals may be particularly damaging to bearings because rollers may skid during the sudden relocation of the loaded zone. Micropitting, a form of surface fatigue, is one example of damage in bearings that can affect its longevity.

Wind turbinegenerator

I’ve heard power is produced 30% of the time and the unit has to be shut down at high wind velocities and low temps. Is this true and would you provide me the facts for turbines being constructed in my area. Can you obtain wind power from other areas transfer it to areas where the wind and/or temp is limiting wind power production. Otherwise do you rely on fossil fuel power production to fill in the gap for the power grid need. Thanks.

This gearbox design has also proven economical for turbines with power ratings between 500 kW and 2.5 MW. However, longevity is the one challenge still unmet in the wind-turbine gearbox industry. Turbine gearboxes are typically given a design life of 20 years, but few make it past the 10-year mark.

8613869596835

8613869596835