PFS 3208 Display Interface Strips - 3208

When you come to Claypool Pump & Machinery’s for St Louis pump repair (whether it be for a small pump repair or a larger pump), you’ll be provided with an estimate, usually within as little as one to three days. Payment can be made by check or Visa/MasterCard and customers who qualify may pay on account.

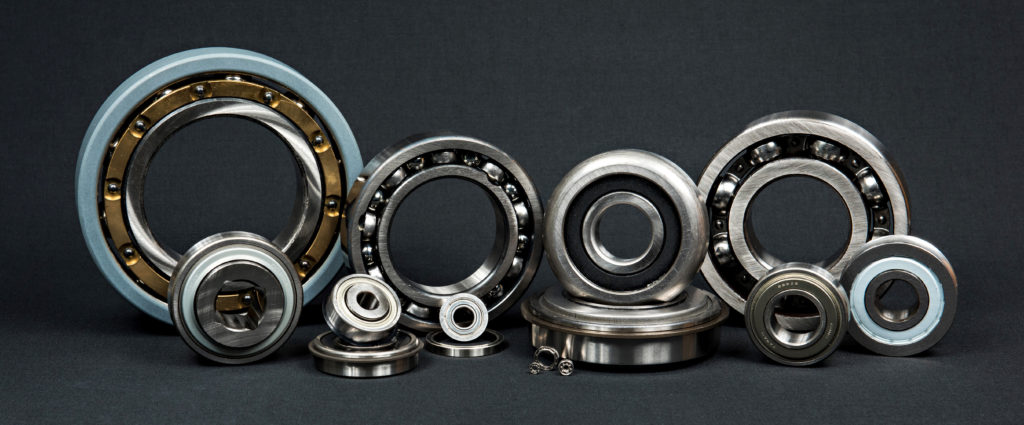

Bearings and bearingscatalog

For your commercial and industrial St Louis pump repair needs, Claypool Pump & Machinery offers you a our in-house repair services that include a full machine shop, lathes, presses, and mounting pumps. We repair and fix fire pumps, domestic water pumps, and industrial pumps for municipal, industrial and HVAC markets. While we specialize in repairing pumps of all types and brands, Claypool Pump & Machinery’s staff is experienced in diagnosing and troubleshooting fire pump infrastructure.

A thrust bearing is a type of rotary bearing. Like other rotary bearings, it allows rotation between parts and supports a high axial load. A thrust bearing consists of two washers or raceways and its rolling elements.

Spherical roller bearings have two rows of rollers that run on a common sphered raceway in the outer ring, the inner ring raceways each being inclined at an angle to the bearing axis.

Typically our standard St Louis pump repairs can be made within three to five days (depending on availability of parts). We offer in-house rush repair services however we recommend calling us to determine the scope of your pump repair emergency and the time frame for a rush service order.

Bearings and bearingschart

There are different types of thrust bearings, differentiated by the application and the amount of axial load they support. For example, thrust ball bearings are utilized in applications where there is little axial load. Spherical roller thrust bearings, on the other hand, are often seen in applications that feature a high axial load, and can also support shafts that are out of alignment.

Bearings and bearingssizes

Bearings and bearings-related products are very important components in most machinery. Their primary purpose is to roll by minimizing friction. Various applications require bearings explicitly designed to handle a particular kind of load. For instance, most radial ball bearings can handle both radial and thrust loads. While roller bearings are better suited where only radial loads are required. The intended use for the bearings should be considered along with load ratings, limiting speeds, before selecting and installing a particular type of bearing.

Have a question or looking for a specific bearing or bearing-related product? Contact the Consolidated team or visit our online catalog!

Ballbearings

Cylindrical roller bearings can handle minimal axial loads in one direction. Double-row cylindrical roller bearings have high radial rigidity and are used primarily for precision machine tools.

They can handle radial and a limited axial (or thrust) load. Deep groove ball bearings are a good option if a load is applied to the bearing from both the side of a shaft (radial) and along the shaft (axial).

There are multiple types of cylindrical roller bearings. Single row cylindrical rollers are the most popular and are separable, which makes for easier mounting and dismounting. However, these may not be able to support the radial load of certain applications. Double row and multi-row cylindrical roller bearings offer greater radial load capacity and can also transmit axial loads in one direction.

IndustrialBearingsnear me

Spherical roller bearings work best in low- to medium-speed applications and can perform well in tough environments and are used in countless industrial applications, where there are heavy loads, moderate speeds and possibly misalignment. Some common applications are gearboxes and wind turbines.

Like other styles, cylindrical roller bearings have various clearance and lubrication options available depending on the manufacturer and supplier. Cylindrical roller bearings can be made with a cage or as a full complement, without a cage.

Rollerbearings

Bearings and bearingsnear me

Deep groove ball bearings are the most widely used bearing type and are extremely versatile. They have low friction and are optimized for low noise and vibration which enables high rotational speeds. The purpose of deep groove precision ball bearings is to reduce rotational friction and support radial and axial loads. Radial Ball bearings can support moderate radial loads and moderate axial loads (parallel to the shaft). They can operate at high speeds (400,000 RPMs and higher).

Spherical roller bearings consist of solid outer rings with a concave raceway, solid inner races, rollers with cages. Inner rings have either a cylindrical or a tapered bore. The concave outer ring and the symmetrical barrel rollers compensate for angular misalignment. They can support axial forces in both directions as well as high radial forces. They are designed for very high load carrying capacities. Sizes are also offered sealed.

If your pump can’t be repaired or if we find that it doesn’t make financial sense to invest more into it, don’t forget that we’re an authorized St Louis pump distributor for major pump brands and as a leader in St Louis pump sales, we can provide alternative pump solutions to replace it, tailored to your specific pumping application.

All types of thrust bearings are found in higher speed applications such as the automotive and aerospace sectors. As such, they require oil lubrication.

Types ofbearings and bearings

Spherical roller bearings can simultaneously support substantial axial and radial load combinations of the rolls and cylinders used. They tolerate misalignment between the shaft and housing.

The main difference between cylindrical roller bearings and other bearing products and styles is in the name – they use rollers, instead of balls, to reduce friction. The rollers are slightly greater in length than diameter. Compared to ball bearings, cylindrical rollers have a greater radial load capacity. The cylindrical roller design provides ease for applications that operate at relatively faster speeds than other styles of roller bearings.

8613869596835

8613869596835