Pinewood Derby Graphite Lube Fastest Car - graphite powder pinewood derby

Home Engineering Book Store Engineering Forum Applications and Design Beam Deflections and Stress Bearing Apps, Specs & Data Belt Design Data Calcs Civil Engineering Design & Manufacturability Electric Motor Alternators Engineering Calculators Excel App. Downloads Flat Plate Stress Calcs Fluids Flow Engineering Friction Engineering Gears Design Engineering General Design Engineering Hardware, Imperial, Inch Hardware, Metric, ISO Heat Transfer Hydraulics Pneumatics HVAC Systems Calcs Economics Engineering Electronics Instrumentation Engineering Mathematics Engineering Standards Finishing and Plating Friction Formulas Apps Lubrication Data Apps Machine Design Apps Manufacturing Processes Materials and Specifications Mechanical Tolerances Specs Plastics Synthetics Power Transmission Tech. Pressure Vessel Pumps Applications Re-Bar Shapes Apps Section Properties Apps Strength of Materials Spring Design Apps Structural Shapes Threads & Torque Calcs Thermodynamics Physics Vibration Engineering Videos Design Manufacture Volume of Solids Calculators Welding Stress Calculations Training Online Engineering

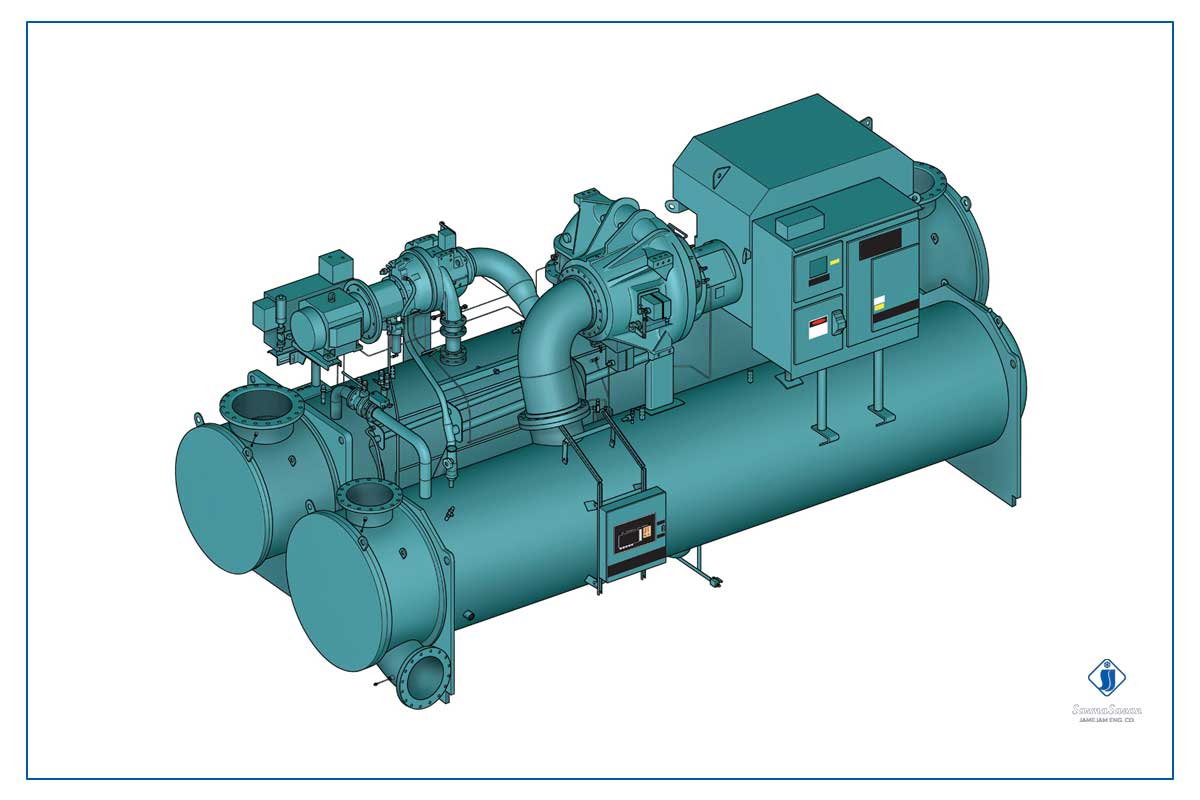

RotaryCompressor HVAC

There are three types of open, closed and semi-closed systems for centrifugal chillers. The opening and closing of these chillers depend on how the mechanical and electrical parts of the chiller are connected. In fact, different parts of a chiller are formed, each of which was used in a special way. In a centrifugal chiller, mechanical equipment such as impellers are considered mechanical parts, and the chiller motor is powered by electricity to provide propulsion to the mechanical parts.

Centrifugal compressor hvacdiagram

Sarma Sazan Jamejam is one of the active and leading groups in the installation industry in Iran. It started its career from the early days with a special structure and coherent and relying on a unique unit in order to meet some needs of builders of luxury construction units, including commercial, residential, as well as hospital and hotel projects. The SSJ eng. Company with years of experience and significant presence in various construction projects from the beginning of its establishment has tried to always improve the quality of all its activities by applying correct and innovative management methods in product selection, sales and especially after-sales services to be customers choice.

Since the gas refrigerant pressure is not high enough when it enters the compressor, the rotation of a propeller is used to generate its driving force to increase the gas refrigerant pressure. In a centrifugal chiller, the structure of a centrifugal compressor is such that it uses a propeller or impeller to flow the gas refrigerant and create a centrifugal force. Thus, in this compressor by the centrifugal force, the kinetic energy of the gas refrigerant increases the refrigerant pressure and in the continuation of this event, the gas refrigerant also increases the temperature.

Centrifugal compressor hvacprice

If the centrifugal chiller is cold water, it means that the condenser is using it for cooling and it needs a chiller cooling tower. Thus another device called a cooling tower; Excess components in the chiller cycle are added to it. In this way, the water in the cooling tower, by transferring heat and exchanging temperature, dissipates the heat in the condenser and lowers the refrigerant temperature. The use of a cooling tower in a centrifugal chiller has its issues. The need for more maintenance and care, increasing the weight and volume of the chiller and high water consumption are some of the negative aspects of having a cooling tower in a cold water centrifugal chiller.

Centrifugalchiller diagram

© Copyright 2000 - 2025, by Engineers Edge, LLC www.engineersedge.com All rights reservedDisclaimer | Feedback Advertising | Contact

The placement of these parts can be done in a single and connected form with the name of closed circuit, which provides few facilities for chiller repair. Also, there is another method called open circuit to connect these two parts, which puts them completely apart. The disadvantage of this system is the risk of leakage of chiller refrigerant.

Centrifugal compressorchiller

Regarding the applications of this chiller, it can be said that since centrifugal chillers have high capacity and efficiency, the application and use of centrifugal chillers includes heavy and large projects.

In general, in any compression chiller, there is a main cycle between its components, which includes the evaporator, compressor, condenser and expansion valve. Meanwhile, the compressor in a chiller is responsible for compressing the refrigerant. This device is located in the chiller cycle, between the evaporator and the condenser. The chiller compressor works by taking the gas refrigerant from the evaporator, increasing the temperature and pressure, and finally transferring it to the condenser to dissipate heat to continue the cycle.

It can be said that there are different categories for chillers. The variety of components inside the building of a chiller and the type of those components can determine the overall type of chiller. For example, the presence of a compressor in a chiller itself determines the type of chiller. Since two general types are defined for chillers and absorption chillers do not use the compressor inside their building, wherever the name of the compressor is mentioned in the chiller, it means that the named chiller is of the compression type. As here, the type of chiller compressor determines the general type of a compression chiller. So when it comes to the word centrifuge in this chiller, it means that the compressor is centrifugal or centrifugal.

The third type of centrifugal chiller, which has a semi-closed circuit, is an open circuit-like system in which the two parts are separated but placed inside a chamber.

Centrifugal compressor hvaccost

Bearing Specification and Design Guide Typical Bearing Life in hours for Various Design Applications Related: Ball Bearings Life Calculations and Load Ratings Bearing Life Formula Based on Speed, Load and Hardness Thrust Bearings Life Ratings Bearing Materials, Ceramic, Chrome Steels, Stainless Steels, and Plastics Critical Speeds of Rotating Shafts Equation and Calculators Application Design life hours Agricultural equipment 3000 – 6000 Aircraft equipment 500 – 2000 Automotive Race car 500 – 800 Light motor cycle 600 – 1200 Heavy motor cycle 1000 – 2000 Light cars 1000 – 2000 Heavy cars 1500 – 2500 Light trucks 1500 – 2500 Heavy trucks 2000 – 2500 Buses 2000 – 5000 Electrical Household appliances 1000 – 2000 Motors ≤ 1⁄2 hp 1000 – 2000 Motors ≤ 3 hp 8000 – 10000 Motors, medium 10000 – 15000 Motors, large 20000 – 30000 Elevator cables sheaves 40000 – 60000 Mine ventilation fans 40000 – 50000 Propeller thrust bearings 15000 – 25000 Propeller shaft bearings > 80000 Gear drives Boat gearing units 3000 – 5000 Gear drives > 50000 Ship gear drives 20000 – 30000 Machinery for 8 hour service which are not always fully utilized 14000 – 20000 Machinery for 8 hour service which are fully utilized 20000 – 30000 Machinery for continuous 24 hour service 50000 – 60000 Application Design life hours Gearing units Automotive 600 – 5000 Multipurpose 8000 – 15000 Machine tools 20000 Rail Vehicles 15000 – 25000 Heavy rolling mill > 50000 Machines Beater mills 20000 – 30000 Briquette presses 20000 – 30000 Grinding spindles 1000 – 2000 Machine tools 10000 – 30000 Mining machinery 4000 – 15000 Paper machines 50000 – 80000 Rolling mills Small cold mills 5000 – 6000 Large multipurpose mills 8000 – 10000 Rail vehicle axle Mining cars 5000 Motor rail cars 16000 – 20000 Open–pit mining cars 20000 – 25000 Streetcars 20000 – 25000 Passenger cars 26000 Freight cars 35000 Locomotive outer bearings 20000 – 25000 Locomotive inner bearings 30000 – 40000 Machinery for short or intermittent operation where service interruption is of minor importance 4000 – 8000 Machinery for intermittent service where reliable operation is of great importance 8000 – 14000 Instruments and apparatus in frequent use 0 – 500

Centrifugal compressorworking principle

For centrifugal chillers, like any other compression chiller, two types of cold water and cool air are defined. Speaking of these two types, it goes back to the type of operation of the chiller condenser. It basically means what the driving force of a condenser is and whether a condenser uses water or the surrounding air to cool itself.

Turbocharger centrifugal chiller or turbocharger chiller is a centrifugal chiller that works without oil, without mechanical contact and without friction. This means that the chiller of the turbocharged centrifuge chiller is based on a magnet. In a turbocharged centrifugal chiller, the impeller creates a magnetic field during operation and rotation, so that no contact is made with the magnetic bearings.

Air-cooled centrifugal chiller but no additional attachment required. This means that the condenser discharges the heat in the surrounding air and in fact the outside air.

As a result of this type of operation, the turbocharger compressor has a long service life. Other advantages of the turbocharger compressor include noise pollution and low vibration. Also, the weight and volume of these compressors are significantly less than similar models. However, this mode of operation requires precise and digital control of the device. This compressor also has a refrigerant suction duct to enter and a refrigerant discharge duct to move to the condenser, and for better performance and repetition of the impellers, two impellers are used inside a turbocharger compressor.

For this compressor, there are two inlet and outlet ducts in the form of a suction duct and discharge duct to take the gas refrigerant from the evaporator and after the process, direct it to the condenser. This is what a compressor should do because the main task of the compressor in chillers is to compress the refrigerant. In general, the efficiency of a centrifugal chiller or centrifuge is directly related to the speed of its impeller.

A centrifugal chiller, like any other chiller that is part of an air conditioning system, is a device that uses thermodynamic laws to dissipate heat and balance temperature. But what is this chiller? It should be said that the word centrifuge in this chiller refers to its compressor section.

8613869596835

8613869596835