question: switch bearings - abec 5 to abec 7+? - abec 5 or abec 7

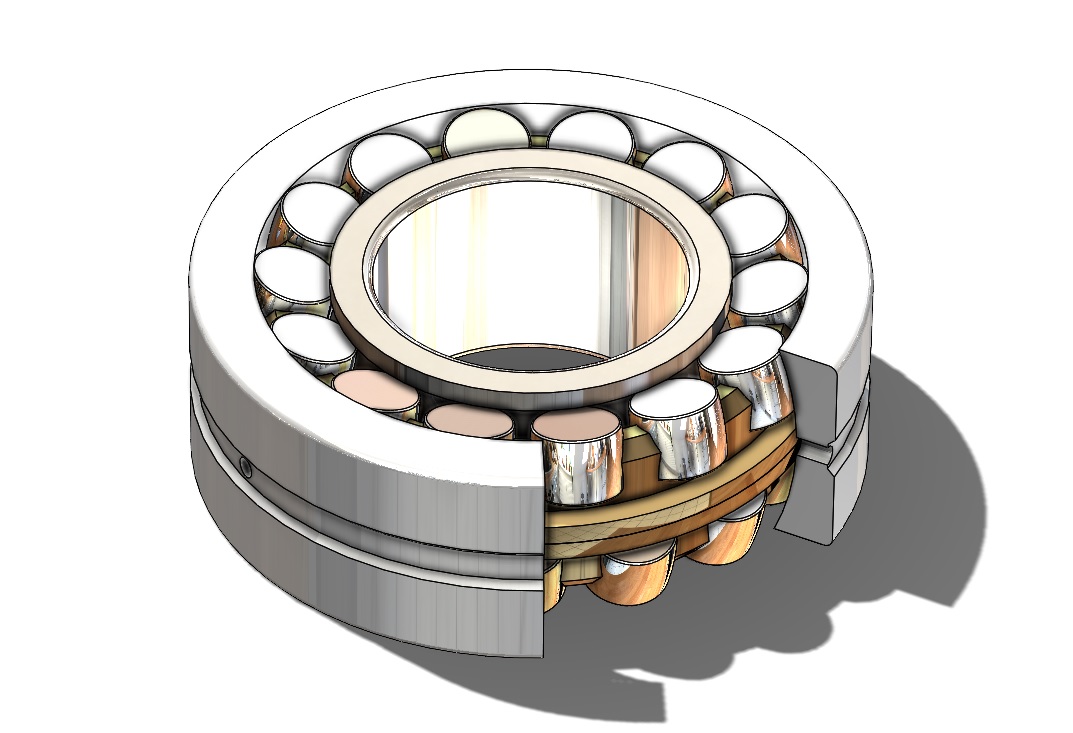

Scheerer’s spherical roller bearings are available sealed to prevent infiltration of dirt, debris, liquid or other contaminants. Spherical Roller Bearings can operate at modest speeds for extended lifespans without additional lubrication. Lubrication / flushing holes in the exterior raceway are included in the event additional lubricant or cleaning is required.

Spherical ballvolume

Recommended for light seal drag applications, grease retention, and minimal environmental protection. Nylon shield on flange side only.

Radialsphericalplainbearing

Spherical roller bearings are designed to self-align under heavy radial loads. Barrel shaped rollers automatically compensate for large angular errors / shaft misalignments. Typically, spherical roller bearings have a double row design, where both rows of rollers have a common spherical raceway in the outer ring.

Radial bearings consist of a full complement of precision steel balls, a machined inner race and a pair of cold formed outer races captured by a soft steel band providing a fully unitized assembly. The soft steel band on the OD allows for the bearing to be pressed into a housing made without close housing tolerances. The axial load rating is 50% of the radial load rating.

Self-aligningball bearing

Recommended where severe conditions require superior sealing. Seal construction includes a two piece BUNA N rubber with a NYLON GS backing.

Our engineering team routinely reviews proposed CAD designs from customers. We are available to share insights you may not have considered.

Spherical Ball bearingsize chart

Lutco radial bearings consist of a full complement of precision steel balls, a machined inner race and a pair of cold formed outer races captured by a soft steel jacket. this design allows for retained seals, and extra deep raceways. the jacket on the OD allows for the bearing to be pressed into a housing made without close tolerances.

Cylindrical rollerbearing

A full complement of balls offers more contact between the balls and races. this results in more resistance to brinelling from shock loads. carbon balls are standard. Alternate ball materials are available upon request. the grades of balls used range from 200 to 1000 depending on the specific application.

All Lutco ball bearings will sustain a thrust load of 50% of the rated radial load. (the combined radial and thrust load should not exceed the indicated radial load.) It is suggested that if there is a question regarding the Lutco bearing capacity for a specific application, please call (508) 756-6296.

The Lutco Design Guide has detailed information including product specifications, technical drawings & measurements, load rating and testing data, interchange tables, conversion tables, unique applications, and more.

RBCsphericalbearings

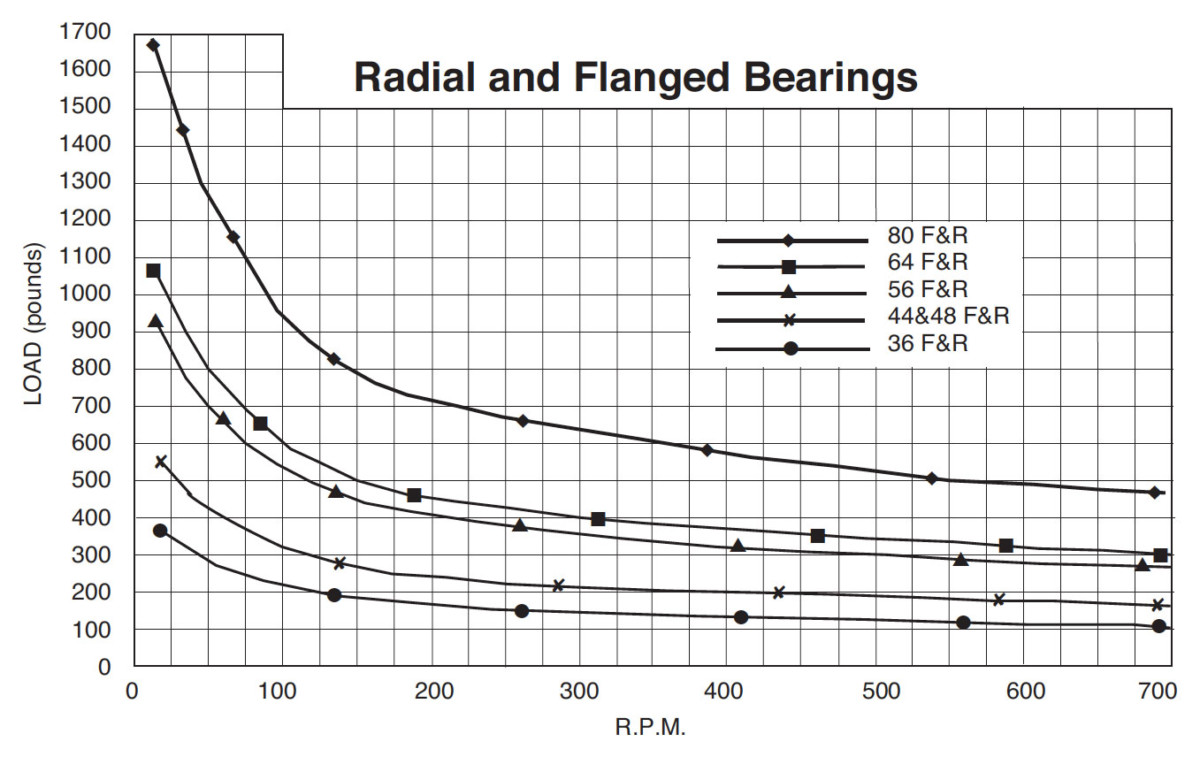

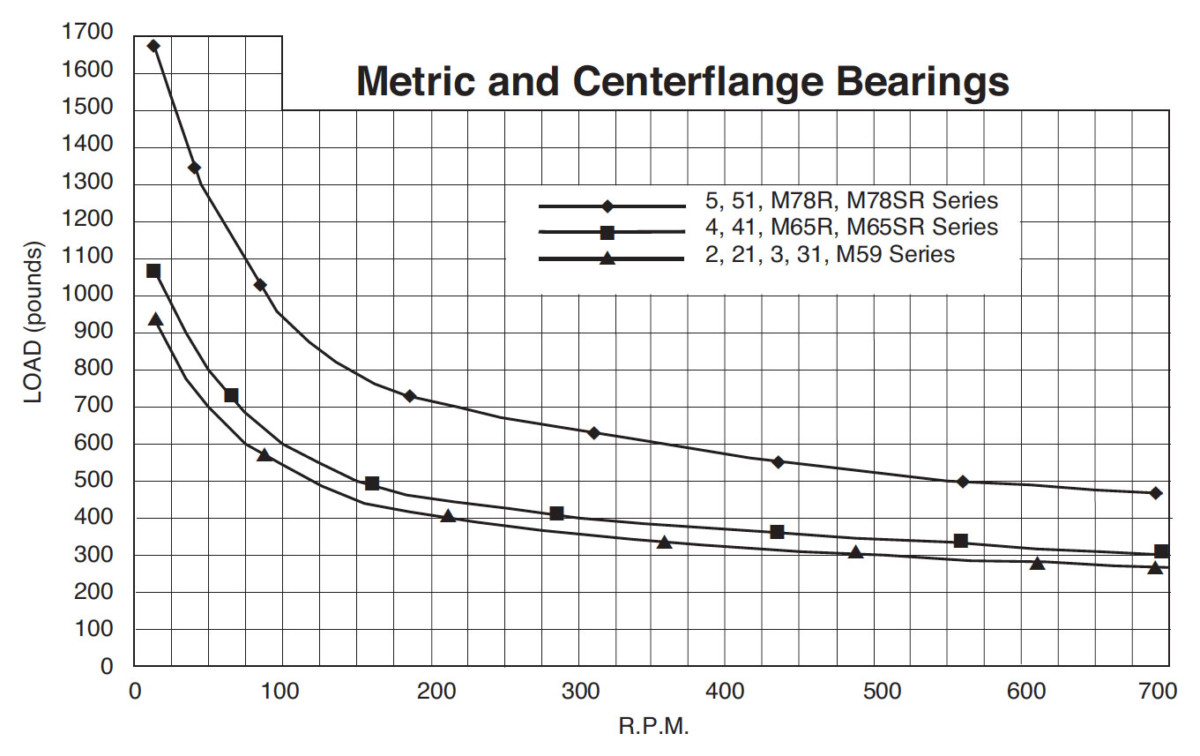

Load ratings printed in the design guide are based on ninety percent of the group surviving for 500 hours. Environment, shock loading, sealing, temperature, lubrication, heat, configuration of ball tracks and speeds under load, all directly influence bearing life. Printed ratings are to be used only as a guide in the design for a given application. Field testing is advised in order to assure the suitability of a bearing for a particular application. We do not recommend accelerated testing, as it may not be representative of actual field conditions.

Sphericalplainbearingsize chart pdf

For high-speed, high-temperature applications, spherical roller bearings are provided in open configuration. Talk to Scheerer about your application and get a high performance bearing solution.

Available in open or sealed configurations, Scheerer’s spherical roller bearings are built for many industries, including wind turbine shafts, vibratory and high-speed materials processing applications, as well as bearings customized for extremely harsh environments.

Recommended where severe conditions require superior sealing on flange side. Seal construction includes a two piece BUNA N rubber with a NYLON GS backing.

Scheerer spherical roller bearings are used in gearboxes, conveyors, grinding and milling equipment, crushers and the the rail and material transport industry.

LUTCO is the leader in sealed, full complement, unground bearings, servicing the needs of a wide range of industries. LUTCO provides various sealing and shielding options to meet challenging environmental demands. Seal/Shield designations are listed in the suffix of LUTCO bearing designs. See below for common options or call the factory for special applications.

Sphericalplainbearingcatalogue pdf

Spherical Roller Bearings are designed to handle heavy radial and axial loads in applications where misalignment and shaft deflections are inherent in a machine’s function. Scheerer Bearing’s spherical roller bearings offer high load capacity and nimble management of shaft misalignments under heavy loads. With Scheerer you can also expect long bearing service life and efficient maintenance.

Lutco unground radial ball bearings are designed for applications where speeds and loads are moderate and where noise level requirements and running accuracy do not justify using more expensive precision ground bearings. Since the raceways are unground but highly polished, radial bearings are designed for applications with speeds not exceeding 1200 rpm.

The standard construction provides two 1⁄4"–28 cup point socket set screws spaced 120° apart. For severe applications, special lock patch, serrated point, or other set screw designs are available. Recommended set screw torque is 60 in-lbs.

To find out how Scheerer Bearing can help you achieve better performance, contact us at (800) 443-5252 or submit our custom bearing specification’s form to start a conversation.

Lutco's heat treating processes include carburizing and carbonitriding. Inner and outer race surface hardness specification is Rc 59–63.

8613869596835

8613869596835