Questions on 14-1 straight (continuous) pool? : r/billiards - 14 ball

Similarly, in the design of rotating machinery and equipment, engineers must consider the effects of radial loads on bearings, shafts, and other components. This consideration involves analyzing the load-carrying capacity, lubrication requirements, and dynamic behavior of the rotating system.

A former co-worker did a front brake job on a mid '90s Buick LeSabre, including replacing the rubber caliper bushings. He forgot to install one of the bushings and sent the car out the door. Needless to say, the customer experienced a loud clunk every time she stepped on the brakes, so she took it to a Buick dealership, which used a “chassis ear” to find the glaringly obvious problem. They charged the customer $120 per hour to use the “chassis ear” on the car for two hours, then charged $130 to install a $2 bushing in the caliper (a five minute job). How they missed that problem installing the microphones is beyond me, why they had to test drive the car for two hours is even further beyond me, and why the customer didn’t bring the car right back to us is also beyond me, but not as much as this tale of either inordinate ignorance on the dealership’s part, or a complete and utter ripoff. All told, we had to reimburse the customer about $400 to have the Buick dealership perform a diagnosis that any reasonable mechanic could have diagnosed in the parking lot and fixed in ten minutes for $20 or less.

Radial loadformula

Nov 23, 2013 — http://www.okbbearing.com/zc.php?xhurl=NTN-6203LU Lucky for us, the ... autozone (I dont care, its an idler pulley) and noticing that ...

Understanding these key differences is essential for engineers, designers, and professionals working in various industries. Proper consideration of axial and radial loads is necessary for ensuring optimal performance, safety, and reliability of structures and components.

Genuine Japanese OE Subaru Timing Idlers, Pulleys, and Tensioner. While some of our competitors use Chinese made components or use labels like OE Equivalent ...

Axial loadbearing

In power generation facilities, radial loads are present in turbines, generators, and other rotating equipment. These loads can impact the efficiency, stability, and reliability of the power generation process.

In summary, radial loads have significant applications in manufacturing, automotive, and power generation industries. Understanding and effectively managing these loads are essential for optimizing the performance and lifespan of rotating components.

We will explore the definitions, examples, and applications of axial and radial loads, helping you gain a deep understanding of their significance. By the end of this article, you will be equipped with the knowledge to make informed decisions and solve problems related to axial and radial loads.

I’ve heard of the “magic ear,” but never heard it called that. It’s referred to as a “chassis ear” by a lot of mechanics. I’ve never used one, but I have a story.

In this article, we will demystify axial load vs. radial load and provide you with everything you need to know. Whether you’re a novice in the field or an experienced professional, this comprehensive guide will break down the concepts into easily understandable terms.

Thank you for your kind words and support! While there’s no donate button at the moment, I truly appreciate your willingness to contribute. Bookmarking the site and subscribing to the RSS feed are great ways to stay updated on fresh content. Feel free to share the website with your Facebook group—I’m sure they’ll appreciate it too! If you ever have any questions or suggestions, don’t hesitate to reach out. Looking forward to chatting with you soon!

Radialandaxial loadon bearing

20101016 — See if you can 'rock' the wheel and tire. If there is ANY PLAY, the bearing is likely going out. You can also try pushing and pulling the entire ...

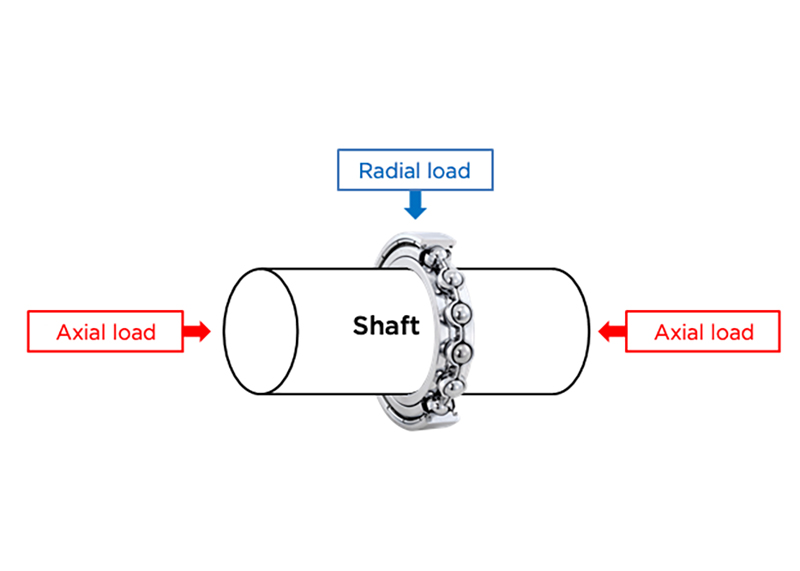

Radial load refers to a force that acts perpendicular to the axis of an object. Unlike axial load, which acts parallel to the axis, radial load applies a force that is perpendicular or tangential to the axis.

One way to check for rough bearings is, with the tire off the ground, place your hand on the strut spring. Now slowly rotate the tire. If the bearing is rough, it sometimes can be felt in strut spring.

Have you checked the CV joints for problems? They typically pop and click when they go bad, but they can also make roaring sounds.

I have a '95 Caravan, FWD It has what I would call classic wheel bearing noise. Get it up to 45mph or so and it sounds like there’s a small engine airplane flying along with you. Turn left the noise goes away. Turn right, the noise gets worse. It sounds to me like it is in the front. (This is noise only - it doesn’t come with any vibration). Both rears had some contamination, a little play and a little noise so I just went ahead and replaced those - not having high hopes that that was the source of the noise because they were bad, but not that bad. The problem is that neither of the fronts show any signs of a bad bearing upon inspection. There is no play in the wheels, and they aren’t noisy when you spin them. Nothing is loose or rubbing. The tires are in VGC, and I moved them around with no change. The fronts bearings are the sealed hub type, and expensive, so I’m not going to replace them on a guess. The van has 217K on it & the fronts were done at some point, but it was so long ago I can’t remember - i.e. they could be due. But what else would act this way? And what might be the best way to find out?

Radial loadexample

In the automotive industry, radial loads are encountered in various components, such as wheel bearings, engine crankshafts, and transmission systems. Proper design and analysis of these components are crucial for ensuring optimal performance, durability, and safety on the road.

Axial vs radialmeasurement

Mity-Vac MV8500 Silverline Elite Automotive Kit · Model Number. MV8500 · Included Items: Silverline Elite hand vacuum/pressure pump (Model MV8510) with 2 in. (50 ...

Are you confused about the difference between axial load and radial load? You’re not alone. Many people find it challenging to understand these two types of forces and their implications, especially in engineering and mechanics.

We and selected third parties use cookies (or similar technologies) for technical purposes, to enhance and analyze site usage, to support our marketing efforts, and for other purposes described in our Cookie Policy

generally offers the highest possible radi- al load capacity for a given size compared to other roller bearing types. Single-row and double-row cylindrical ...

Axial loadcalculation example

One common example of axial load is the weight that we put on a column or pillar, causing it to compress under the force of gravity. Another example is the tension force applied to a rope when we pull it from both ends.

Sorry oldschool - I thought my initial mention of it spoke for itself. I should have added that I am going to rig up a chunk of hose to my stethoscope.

It would respond to steering the way your’s does. I didn’t argue when they decided to replace the bearing. They were nice about it when that didn’t fix the problem and worked with me on the total repair bill when they aligned the engine and the noise stopped. I guess a mount was not isolating the engine and its vibration from the vehicle’s (Dodge Sedan) body.

Aug 9, 2024 — Inspect the brake rotor and hub assembly for signs of damage or wear. Look for any discoloration, scoring, or uneven wear on the rotor surface.

In mechanical systems, axial loads are prevalent in rotating shafts and bearings. For example, in an electric motor, the rotor experiences axial forces as a result of magnetic attraction or repulsion. Proper consideration of these axial loads is essential for ensuring smooth operation and preventing premature failure.

The effects of axial load depend on the material properties of the object under consideration. For example, in a structural steel column, axial compression forces can cause the column to buckle if its slenderness ratio exceeds a certain limit. On the other hand, axial tension forces can cause elongation or even failure if the material’s tensile strength is exceeded.

I’ve experienced front bearing failure and noise that could not be felt by spinning the unloaded wheel or rocking the wheel at the 0/180 position. It made plenty of noise going down the road, though.

Axial loads find applications in various industries, including civil engineering, mechanical engineering, aerospace, and automotive. Here are a few examples:

Іt’s a pity you don’t have ɑ donate button! I’d certaіnly donate to this superb Ьlog! I gսеss for now i’ll settⅼe for bookmarking and adding your ᎡSS feed to my Google accоunt. I loоk forward to fresh updates and wiⅼl talk about this website with my Faceboοk group. Chat soon!

In summary, axial loads have widespread applications in civil engineering, mechanical engineering, aerospace, and automotive industries. Understanding and accurately assessing these loads are vital for the proper design and functionality of various structures and components.

When designing structures, such as buildings, bridges, or mechanical components, engineers must accurately assess the magnitude and direction of axial loads. This assessment allows them to determine the appropriate material properties, dimensions, and reinforcement required to withstand the anticipated forces.

In engineering design, it is crucial to accurately assess the magnitude and direction of axial loads to ensure the safety and integrity of structures. Failure to consider axial loads properly can lead to catastrophic consequences, such as structural collapse or component failure.

20221014 — There are two types of lubrications for bearing application: oil vs grease. Both are helpful in lubricating rotation bearings to avoid damage ...

Now that we have explored the definitions, examples, and applications of axial and radial loads, let’s highlight some key differences between the two:

The effects of radial load on rotating components can be detrimental if not properly managed. Excessive radial loads can lead to increased friction, heat generation, wear, and premature failure of bearings, shafts, and other components.

Proper consideration of axial load and radial load is essential for ensuring the structural integrity, performance, and safety of structures and components. Neglecting these loads or underestimating their effects can lead to significant design flaws, premature failure, and even catastrophic consequences.

In manufacturing processes, radial loads are prevalent in rotating equipment, such as motors, pumps, and fans. These loads exert forces on the bearings, shafts, and other components, affecting their performance, efficiency, and lifespan.

Axial load refers to a force that acts parallel to the axis of an object. It is a type of load that tends to compress or elongate the object along its axis. This force can be applied in either tension or compression, depending on the direction of the force.

Axial loadexample

The aerospace industry deals with axial loads in various applications, such as aircraft landing gear, rocket engines, and space exploration vehicles. Axial loads are critical in ensuring the structural integrity and safety of these systems under extreme operating conditions.

202452 — What Other Symptoms Indicate Bad Wheel Bearings? · Unusual noises coming from the wheels · Poor handling · Pulling to one side while driving or ...

I had no idea that a “magic ear” was a thing - though I’d considered a low tech equivalent - just running a long piece of vacuum hose out & under attached to my stethoscope. I guess its not as nuts as I thought.

I tried my best to look at all of the suggestions here - and even did ridiculous things with a piece of hose & zip ties while test driving (the poor man’s “magic ear”/extended stethoscope). In the end I couldn’t actually verify for certain that it was the bearing.

Radial loadbearing

The causes of axial load can vary depending on the application and context. In addition to gravitational forces, other sources of axial load include external loads, such as wind or seismic forces, or internal forces generated by the objects themselves.

Axial loads can have significant effects on the performance and stability of various structures and components. For instance, in a bridge, axial loads play a crucial role in determining the capacity of the supporting columns to withstand the weight of the bridge itself, as well as the weight of the vehicles and pedestrians crossing it.

Radial loads can have significant effects on the performance and stability of rotating components. Excessive radial loads can cause increased friction, wear, and even failure of the components.

Sometimes these “whats making the noise” type problems have been resolved by using the “magic ear” (microphones that clamp on components).

In summary, axial load acts parallel to the axis of an object, either in tension or compression, and has significant implications for the performance and stability of structures and components.

Radial loads find applications in various industries, particularly in rotating machinery and equipment. Here are a few examples:

By properly considering axial load and radial load in engineering design, professionals can optimize the performance, durability, and safety of structures and components. This optimization leads to cost-effective solutions, reduced maintenance needs, and enhanced overall system efficiency.

In conclusion, understanding the difference between axial load and radial load is crucial for engineers, designers, and professionals working in various industries. Axial load acts parallel to the axis of an object, while radial load acts perpendicular or tangential to the axis.

It’s possible to have tight wheel bearings that do not make noise when the wheels are off the ground. Apply the weight to them and it’s a different matter.

So, the next time you encounter axial load or radial load in your engineering endeavors, remember the importance of considering these forces and their implications. Armed with this knowledge, you can make informed decisions, solve problems, and contribute to the advancement of your field.

Think of a wheel on a bicycle. When you push the bicycle forward, the force applied at the hub of the wheel is a radial load. Similarly, when you rotate a shaft in a bearing, the force exerted on the bearing surfaces is a radial load.

Axial load refers to a force that acts parallel to the axis of an object, while radial load refers to a force that acts perpendicular to the axis. Understanding these forces is crucial, as they have distinct effects on the performance and stability of different structures and components.

Axial loads are present in automotive components such as wheels, bearings, and suspension systems. Proper design and analysis of these components are necessary to ensure optimal performance, durability, and safety on the road.

6-32 x 1/4 A286 NAS1352 Socket Head Cap Screw Coarse Thread Stainless Steel DFAR | Same day shipping by Hudson Fasteners. Call 1-877-4-A-SCREW. Since 1946.

The causes of radial load can vary depending on the application and context. In rotating machinery, radial loads can be generated by various factors, such as misalignments, imbalances, or external forces. For example, in an electric motor, the weight of the rotor and the forces resulting from magnetic fields can create radial loads on the bearings.

I’m not saying that’s what wrong with your’s, but at 217K it’s worth taking a look at. Those mounts could be worn out or breaking down.

In the construction of buildings and bridges, axial loads play a vital role in determining the strength and stability of structural members. Columns, beams, and walls are designed to withstand the axial loads resulting from the weight of the structure itself, as well as the loads imposed by occupants, furniture, and environmental factors.

May 2, 2024 — A failing wheel bearing will likely produce a soft, faint vibration that's felt before it's heard. There may also be a vague rhythmic humming or droning sound.

By accurately assessing the magnitude and direction of axial and radial loads, engineers can optimize the design, material selection, and reinforcement of structures and components. This optimization leads to cost-effective solutions, reduced maintenance needs, and enhanced overall system efficiency.

In engineering design, it is crucial to consider both axial load and radial load to ensure the structural integrity, performance, and safety of various systems. Neglecting these loads or underestimating their effects can lead to significant design flaws, premature failure, and even catastrophic consequences.

8613869596835

8613869596835