R&M Bearings : Skateboard Bearings - skateboard bearings measurements

The bearing clearance refers to an uninstalled rolling bearing and can be described as the internal mobility of the rolling elements and the rings in both axial and radial directions. The operating clearance can also be described as the internal mobility of the rolling elements and the rings in both directions, but it refers to an installed bearing in operation.

Only extreme values are taken into account, which cover the range when the “largest” bearing is mounted on the “smallest” shaft or the “smallest” bearing is mounted on the “largest” shaft. In this example, this would be the following cases:

Buy this 2010 Nissan Altima Rear Wheel Bearing car part. Availability: In Stock. Search our entire inventory of recycled auto parts direct from salvage ...

Formula 13 can be used to calculate the reduction in bearing clearance. For the sake of simplicity, factors such as the shape of the bearing, shaft and housing as well as the materials used are taken into account by a numerical value of 70%-90%. In general, the larger the interference, the more the bearing clearance is reduced.

The most practical way to explain internal clearance is to imagine a bearing (for example, a deep groove ball bearing) that you are holding in your hand. If you try to move the inner ring of this bearing up and down or to the left and right while holding the outer ring, you will notice a small displacement in the radial (black arrow) or axial direction (purple arrow). This displacement is called bearing clearance. Conversely, the inner ring can also be held and the outer ring moved up and down or to the left and right. This is also referred to as bearing clearance.

Even though the operating clearance should (theoretically) ideally be slightly negative in order to achieve maximum bearing life, in practical everyday life under normal operating conditions, operating clearance is usually targeted at just above zero. The reason for this is that this negative operating clearance (preload) could increase if a rolling bearing is exposed to changing operating conditions. This would in turn lead to the reduction in service life already described.

So far, this article has been about bearing clearance classes and how they change during operation. But depending on the application, it may be necessary to preload bearings axially.

Damn, bearing damage! If you consider that rolling bearings are exposed to continuous pressure and shear stress, this is nothing unusual to begin with. What

A bad wheel bearing can lead to uneven tire wear and it could be dangerous when driving. Here the signs that you need to change your wheel bearing.

According to the American Heart Association (AHA), a reading of 180/120 mm Hg or higher is termed a hypertensive crisis and requires immediate medical attention. If this reading is consistent two times in a row, five minutes apart, then you must head to the nearest emergency room immediately.

If you have already read the articles on angular contact ball bearings or tapered roller bearings, you may already have come into contact with different

Bearing clearance and operating clearance, isn’t that the same thing? And preload, I’ve heard that before, but what is that supposed to be?! How do I calculate all these values and what criteria are important when choosing the right operating clearance? Perhaps you are confronted with such questions – you will find the answers and more detailed information in this article.

Some force is needed to mount the 6008C4 on the shaft to overcome the interference. Due to this interference, the bearing clearance is reduced so that after mounting on the shaft it becomes +3µm -> +44µm. Now the shaft is mounted with the 6008C4 inside a steel housing. In this example, the housing has a H6 (0µm/+19µm) tolerance and the outer ring of the bearing has a tolerance of 0/-13µm.

As you can see, the resulting fit between the outer ring and the housing is a clearance of 0µm – 32µm. This does not change the clearance in the bearing: +3 -> +44µm.

Dialogue · Willy: Why the hell you need ball bearings for? · Fletch: Awww, come on guys, it's so simple maybe you need a refresher course. [leans arm on hot ...

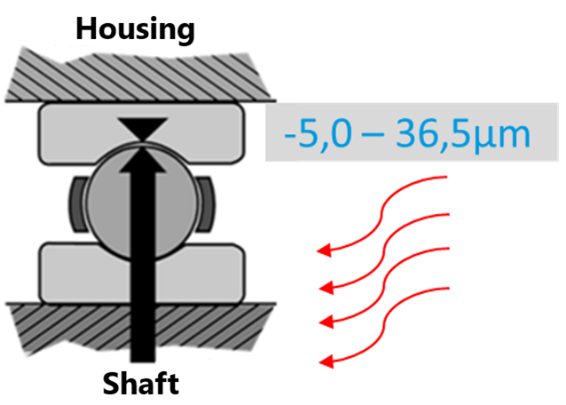

We can now say that the bearing clearance in the operating state is -5.0µm to 36.5µm. This bearing clearance during operation is also called operating clearance. The corresponding changes to the bearing clearance depending on the assembly condition can be seen in the table.

The bearing clearance is reduced due to interference δf between the inner ring and shaft or outer ring and housing. Due to the interference δf between the inner ring and the shaft, the inner ring expands or the outer ring contracts (interference between the outer ring and the housing) during mounting.

Blood pressure readings above 180/120 mmHg are considered stroke-level, dangerously high, and require immediate medical attention.

According to guidelines by the American College of Cardiology/American Heart Association, hypertension is a term to describe high BP that measures consistently above 130/80 mm Hg or higher.

Treating high blood pressure may include a combined approach of dietary changes, medication, and exercise. The goal is to lower your blood pressure and thus lower your risk of developing health problems caused by high blood pressure, such as heart disease.

The most effective method to detect which bearing is going bad is by play in the wheel when jacked up, like others have said, or by heat depending on how bad ...

A severe increase in blood pressure (BP) that can lead to a stroke is called a hypertensive crisis. Extremely high blood pressure can damage blood vessels and weaken arteries in the brain, increasing the risk of stroke.

Find O'Reilly Auto Parts stores nearby as well as information on which in-store services are available at the nearest O'Reilly locations.

©1996-2024 MedicineNet, Inc. An Internet Brands company. All rights reserved. Terms of Use. MedicineNet does not provide medical advice, diagnosis or treatment. See additional information.

20241120 — Watch out for the following symptoms that may indicate a faulty bearing. worn out wheel bearing closeup look Driving with bad wheel bearings can ...

But enough theory. What about the bearing clearance in a practical example? For a bearing 6008C4, for example, the radial internal clearance is 28-46µm (= C4). In the first step, bearing 6008C4 is mounted once on a steel shaft that has, for example, a k6 tolerance (+2 -> +18µm). Since bearing 6008C4 has a tolerance on the inner ring of 0/-12µm the resulting fit between the inner ring and the shaft gives 2 to 30 microns of interference. This value is obtained by looking at the tolerances on the bearing inner ring and the shaft.

There are different groups of radial internal clearance for rolling bearings. These can be seen in the table. (Note: The axial internal clearance can be calculated from the radial clearance using formulae, for example for deep groove ball bearings).

The shaft is then rotated at 8,000 rpm, for example. The bearing 6008C4 now has a temperature of 100°C on the inner ring and 90°C on the outer ring. But what is actually happening now? Well, the inner ring and the outer ring expand due to the heat, but the inner ring expands more than the outer ring due to the temperature difference. Because of this, the clearance in the bearing is reduced from +3 -> +44µm to -5.0 -> +36.5µm. This reduction of about 7.5µm is calculated with a computer programme or alternatively with the help of catalogue formulas.

The internal mobility of the rolling elements and the rings in the axial and radial direction is referred to as bearing clearance Bearing clearance refers to an unmounted rolling bearing Operating clearance refers to a mounted rolling bearing in operation Typical bearing clearance classes (values for a deep groove ball bearing 6008): C2 (1->11µm) -> CN -> C3 -> C4 (28->46µm) Preload is defined as either a negative radial operating clearance or the axial preloading of a rolling bearing by means of a spring or a clamping system

To calculate the operating clearance, factors such as fits as well as temperature differences that occur between the inner and outer ring must be taken into account.

You will certainly not come across CN, C3 and C4 for the last time. The other bearing clearance classes are only used under special operating conditions.

While hypertension is sometimes called the silent killer because most people show no symptoms, a few common signs of the condition include:

SNR Wälzlager GmbH creates the information for this website with great care and endeavors to ensure that it is up-to-date, correct and complete. SNR Wälzlager GmbH assumes no liability and is not liable for any material or immaterial damage caused by the use of the service, unless it can be proven that it was caused by intent or gross negligence.

The angular contact ball bearing is virtually the brother of the deep groove ball bearing. Characteristics of angular contact ball bearings Perhaps you already know

While they can be tricky to remove and replace, with a little elbow grease and know-how, you can repair your worn out wheel bearings.

In order to determine the raceway diameter of the outer ring again Do (approximately), one must use formula 15 or formula 16, depending on the type of rolling bearing.

Characteristics of tapered roller bearings Here you see an NTN tapered roller bearing. As the name suggests, tapered roller bearings are roller bearings, whereby the

PVC insulating tubes - PCV 16X1,5 VL (60 M) ; Material, PVC, plasticized (unleaded) ; Operating temperature [°C], -40 ÷ +70 ; Colour, violet ; Wall thickness [mm] B ...

Another application is the bearings in a machine tool spindle (hence the name spindle bearing). Here, the spindle bearings are axially preloaded either by means of a spring, as with the electric motor, or alternatively via a fixed–position clamping system.

One possibility, which is often used in electric motors, for example, is axial preloading of the rolling bearings by means of a spring (preloading by means of a constant sprung preload force). This is shown symbolically in the illustration. The spring force acts around the entire circumference.

Why is this done? The spring preload force causes all the balls to fit snugly against the raceways of the deep groove ball bearing (axial bearing clearance = 0µm). The preload thus causes a tension at the contact points of rolling elements and raceways. This reduces the operating noise and improves the vibration behaviour.

Oct 21, 2017 — $100 for each bearing and $100 for each bearing installation. $400 total plus the cost of an alignment which ranges from $60 to $100. So figure $500.

Blood pressure (BP) is the force applied against the walls of the arteries by the blood that the heart pumps through the four chambers into major arteries that transport blood throughout the body through the circulatory system.

Interference fit, transition fit, clearance fit. You should know and be able to define these three types of fit after reading this article. But before

Preload is most likely to occur in angular contact ball bearings and tapered roller bearings, and a slight preload also has a positive effect on the overall service life. In the context of preload, one should always consider the purpose and the goal, because preload also carries risks, especially if preload is excessive. Therefore, it shouldn’t be overlooked that this can lead to increased surface pressure, extremely high heat generation and a shortening of the bearing service life.

Formula 12δeff = δo – ( δf + δt )δeff = Effective interference (due to fits), mmδo = Bearing clearance, mmδf = Decrease in bearing clearance due to interference caused by fits, mmδt = Decrease in bearing clearance due to temperature differences between inner and outer rings, mm

If the table for the bearing clearance classes mentioned above is extended by a further column, the balls which “bear” the radial force (for example the weight of the shaft) are shown in the fourth column (load bearing).

6-32 x 1/4 A286 NAS1352 Socket Head Cap Screw Coarse Thread Stainless Steel DFAR | Same day shipping by Hudson Fasteners. Call 1-877-4-A-SCREW. Since 1946.

Materials and manufacturing Have you already had a look at our chapter on structure and function? Maybe you asked yourself what rolling bearings are actually

By clicking "Submit," I agree to the MedicineNet Terms and Conditions and Privacy Policy. I also agree to receive emails from MedicineNet and I understand that I may opt out of MedicineNet subscriptions at any time.

A targeted and careful selection of the bearing clearance is elementary, as the subsequent operating clearance has an effect on the service life (not the L10h service life), the temperature curve, the bearing performance as well as the running noise. The effects of the operating clearance on the service life are shown in the graph.

When calculating the reduction in operating clearance due to a temperature difference, you must take several factors into account.

According to the AHA, normal BP in adults is 120/80 mm Hg. However, according to the new guidelines issued by the AHA, the goal BP for all adults is now less than 130/80 mm Hg.

Formula 14δt= ∝×∆T×Do∝= Temperature coefficient of expansion of the bearing material, 12,5× ((10)*6/℃)∆T= Temperature difference (inner/outer ring) in °CDo= Outer ring raceway diameter, mm

As you can see in the figure, the life span drops rapidly in areas 3 and 1. But why does the service life decrease so much? Let’s assume that the bearing 6008C4 mentioned in the example above has 12 balls (rolling elements). However, if the temperature difference between the inner ring and the outer ring now always increases, the operating clearance will continue to decrease (range 3). As a result, all 12 rolling elements are now in contact, increasing resistance to rotation until eventually sliding occurs (rolling no longer takes place). This reduces the service life to the point of total failure!

The calculation of the value δf is not the whole picture. The next step is to calculate the variable δt which takes into account the reduction of the operating clearance due to a temperature difference in the bearing. An important piece of information: When the bearing is in operation, the outer ring is typically 5 to 10°C cooler than the inner ring, for example. Under certain conditions, such as above-average heat dissipation of the housing, this difference can be even greater.

If a radial force is now added, this increases the radial internal clearance again. The reason for this is that some of the rolling elements absorb the radial load while the other rolling elements are relieved. The rolling elements under load will deform slightly (elastic deformation). In the illustration of radial load, this is shown for a deep groove ball bearing. The length of the yellow arrows indicate the magnitude of the force acting on the rolling elements where the elastic deformation is proportional to the force.

The internal mobility of the rolling elements and the rings in the axial and radial direction is referred to as bearing clearance Bearing clearance refers to an unmounted rolling bearing Operating clearance refers to a mounted rolling bearing in operation Typical bearing clearance classes (values for a deep groove ball bearing 6008): C2 (1->11µm) -> CN -> C3 -> C4 (28->46µm) Preload is defined as either a negative radial operating clearance or the axial preloading of a rolling bearing by means of a spring or a clamping system

Hypertension affects one-third of Americans and is a considerable risk factor for cardiovascular diseases such as heart attack and heart failure, stroke, renal diseases, organ damage, and death.

High blood pressure, or hypertension, is the leading cause of strokes in the U.S. However, understanding risk factors and blood pressure readings can help people seek appropriate treatment:

8613869596835

8613869596835