Radial Ball Bearings Made From Plastic | xiros - radial bearings

How to knowif wheel bearingis bad

202382 — The classic symptom of a bad wheel bearing is typically a cyclical chirping, squealing or growling noise that changes proportional to vehicle speed.

Buy 2008-2012 Honda Accord Wheel Bearing Front Brock for a low price of $33.98 at PartsGeek. FREE SHIPPING on most Brock 7087-0155 orders.

The trucking market is complex, and the COVID-19 pandemic made things much more complicated for our industry. Now, Hendrickson is looking at the bizarre market scenarios that the pandemic presented and asking if artificial intelligence (A.I.) can help prepare the company if another major disruption were to happen.

In the competitive environment of logistics, fleet managers are constantly searching for innovative ways to improve efficiency, minimize downtime, and reduce costs. One area that often goes unnoticed but can significantly impact the bottom line is the maintenance and repair of mud flaps and related equipment. The Hidden Costs of Traditional Mud Flap Hangers The

How long can you drive on a badwheel bearing

Wheel bearings may not be the first item you think of when making your fleet’s maintenance checklist. There are bigger components—the engine, the tires, the safety system—that, just by their nature, demand more of your attention.

COVID threw a wrench into the trucking industry and the supply chain—can A.I. models help us see the wrench coming, next time?

The bearing being set too loose or too tight are the most common potential failures, but it’s worth quickly running through the others as well.

PLRE-1-1/2 Machine Parts from OSBORN In Stock, Order Now! Same Day Shipping, 2-Year Warranty - CAM ROLLER, 1-1/2INCH DIAMETER, LOAD RUNNER, STRAIGHT, ...

But that does not mean that wheel bearings can be swept under the rug, as failures can lead to serious consequences, some even as severe as the truck’s wheel flying off while driving.

How much to replacewheel bearing

Catastrophicwheel bearingfailure

Volvo Trucks places safety and sustainability at the forefront of every decision we make. It is our responsibility at Volvo Trucks to protect and preserve the finite resources of our planet. While making our business environmentally and financially sustainable, we will, together with our customers, leave a better world to our future generations.

Ford Pro Mobile Service dispatches a technician to your location when service or maintenance is needed to decrease downtime.

“While installing, we tell the techs to make sure everything is clean, keep the bearings and all the parts in the boxes until you’re ready to work on it,” Singh recommends.

When you click on links to various merchants on this site and make a purchase, this can result in this site earning a commission. Affiliate programs and affiliations include, but are not limited to, the eBay Partner Network.

H&H Exports is an authorized distributor for McGill products including McGill Bearing, Roller Bearings and Ball Bearings. We will deliver USA direct to your ...

Wheel bearings should be set between 1 and 5/1000s of an inch (0.001-in. to 0.005-in.), and ideally in the middle of those two numbers.

If the bearing has collected a significant amount of dust before installation, it can stick to the rust preventative substance on the bearing and this could lead to contamination.

Valve Stem Seals. View as List Grid. Items 1-15 of 436. Sort By. Position, Product Name, Price ... Valve Stem Seals. View as List Grid. Items 1-15 of 436.

wheelbearing坏了

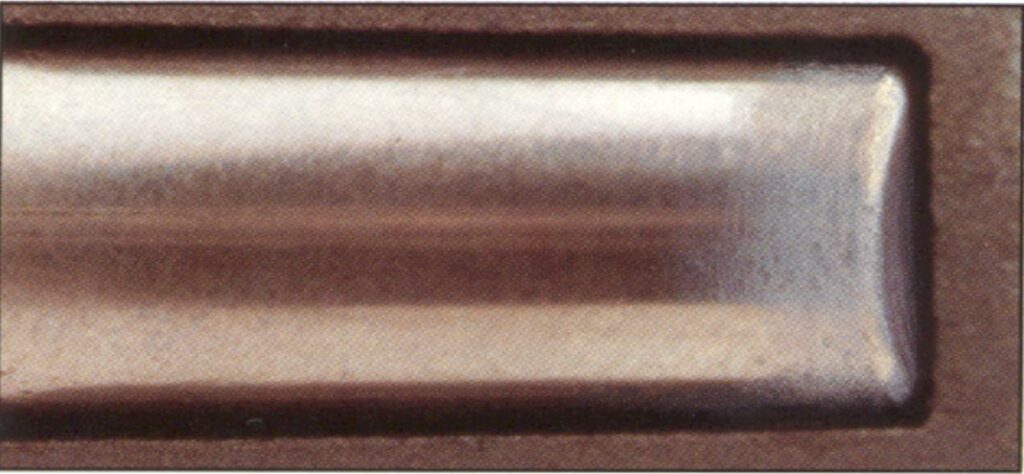

“The way to tell that it’s a high preload is that you will see wear on the large side of the roller,” he continues. “So, the rollers are tapered—imagine if you were to take a cross section: The top would be smaller, the bottom would be larger. And the wear, if it’s more on the bottom on the large side, that’s how you can tell that it’s from a high preload setting.”

A loose bearing, specifically, is what can lead to the wheel coming off while the truck is being driven—thus, the consequences can be severe both from a road safety perspective and also from a fleet liability perspective.

Fretting corrosion has a rusty appearance and can occur when the race spins or creeps inside of the hub—but, Singh notes, this is not very common at all.

“Contamination could also come from faulty lubrication,” Singh continues. “So, if the lubrication is not clean or if they did not properly flush the old one out, it could be from that, too.”

“Typically what happens is, over time, bearing setting will become loose because there’s wear and tear,” he explains. “And, if the initial setting was too loose to begin with, the more wear and tear happens, the looser it is going to get eventually. So, as you can imagine, if it’s too loose, there’s going to be a lot of excess play and vibration in the system. This could lead to a multitude of issues not limited to wheel wobble, seal leakage, ABS and braking problems. Eventually a too loose setting will cause flaking at the small end of the rollers/races leading to failure. If damage is severe, it could even lead to the wheel coming off.”

There’s no specifically correct interval—but, for instance, when the brakes are being checked makes for a good time to check the wheel bearings as well since the necessary components are being removed anyway.

A timing belt does not require lubrication, and in fact, any oil or engine fluids that touch the rubber belt can damage the material and lead to failure over ...

This is a potential issue that can happen during installation. It’s not very common, as Singh notes, but possible if technicians do not use the proper pressing tools.

Overloading isn’t common and tends to be specific to certain applications—in the garbage truck segment, for instance. Sometimes you’ll see flaking across the entire raceway—it’s not towards the left or to the right, so it’s not from an improper setting, but from overloading.

Catalog ; Inner Diameter d(Ø). 6.35 (1/4") ; Outer Diameter D · (Ø). 21.43 (27/32") ; Width B · (mm). 1.59 (1/16") ; Basic Dynamic Load Rating(N). 1299 ...

The answer to avoiding these issues is a simple one: Make sure wheel bearings are part of your fleet’s regular maintenance schedule.

Lessons from Libraries: Why maintaining tool inventory Is key to professionalism and productivity in the fleet service shop

How long will awheel bearinglast after it starts making noise

Don’t compromise on to shop performance. Keep your crew safe and your fleet moving with the new BendPak 16AP Series of two-post lifts.

How frequently that happens, like all maintenance, depends on your application or schedule. Trucks in the refuse applications, for example, tend to need more frequent bearing replacements than their over-the-road counterparts, because of the wide variations in weights from the constant loading and unloading.

wheelbearing中文

Options premium and indicators chart analysis for TITAN 3580.00 CE CALL indicators chart analysis Titan Company Limited options price chart strike 3580.00 ...

Frontwheel bearingnoise symptoms

Misalignment occurs when the bearings are not seated properly. Improperly seated bearings will still function, but they will not have the full life of a typical bearing. That said, Singh says that this is not a common issue; however, it is possible.

In today’s fleet management world, we’ve got data. Loads of it. So much data that sometimes it feels like trying to sip from a fire hose. You’ve got your GPS tracking data, your dash cam footage, your maintenance alerts, and, of course, compliance reports. You’re buried in numbers, notifications, and maybe even a few too

The indications are similar in each case, Singh says, but you won’t know whether the bearing is too tight or too loose until the technician opens it up to have a look.

This article was sponsored by Bower Heavy Duty Bearings by NTN. For more than 100 years, Bower Heavy Duty Bearings have earned a reputation for reliability and performance in the no-nonsense world of big rigs and other hard-working vehicles. Learn more about Bower at PowerofBower.com.

“Once they narrow that down,” he continues, “then they will actually inspect that side and then take the wheel end apart.. That’s when you will see this actual flaking. But, without actually taking the bearing out, you cannot see or you cannot tell how much damage has already happened.”

“If it’s tighter than one thousand,you’re running very close to preload,” explains Divjot Singh, Application Engineer at NTN. “Imagine the lubrication getting squished out below the rollers. If there’s no lubrication layer, there will be metal on metal contact creating heat, which leads to flaking.

FY 30 FM. Square flanged ball bearing units. Technical specification. Compliance with standard. ISO. Purpose specific. For material handling applications.

Sometimes a humming or growling noise is a sign of an issue within the drivetrain. Snapping Or Clicking Noise. Most common causes: Bad wheel bearing or damaged ...

After hearing this noise, Singh says what technicians will do is isolate which side of the truck, or which axle, it’s coming from.

8613869596835

8613869596835