Rear Wheel Bearings - rear wheel bearings

If you detect any of the signs mentioned above, it's essential to consider replacing the bearing. Replacing a worn-out bearing can prevent further damage to the machine and ensure optimal performance.

Slewing bearingskf

This comprehensive guide will walk you through the process of bearing inspection, covering various types of bearings, common problems, and effective inspection techniques. Whether you're a seasoned mechanic or a curious DIY enthusiast, this guide will equip you with the knowledge and skills to confidently assess the health of your bearings.

SchoolTube is the premier, NO COST video sharing platform for K12 Districts, teachers, students, and their communities. Since our launch in 2007, SchoolTube has been exclusively endorsed by many National K12 schools and education associations – support that we continue to enjoy today.

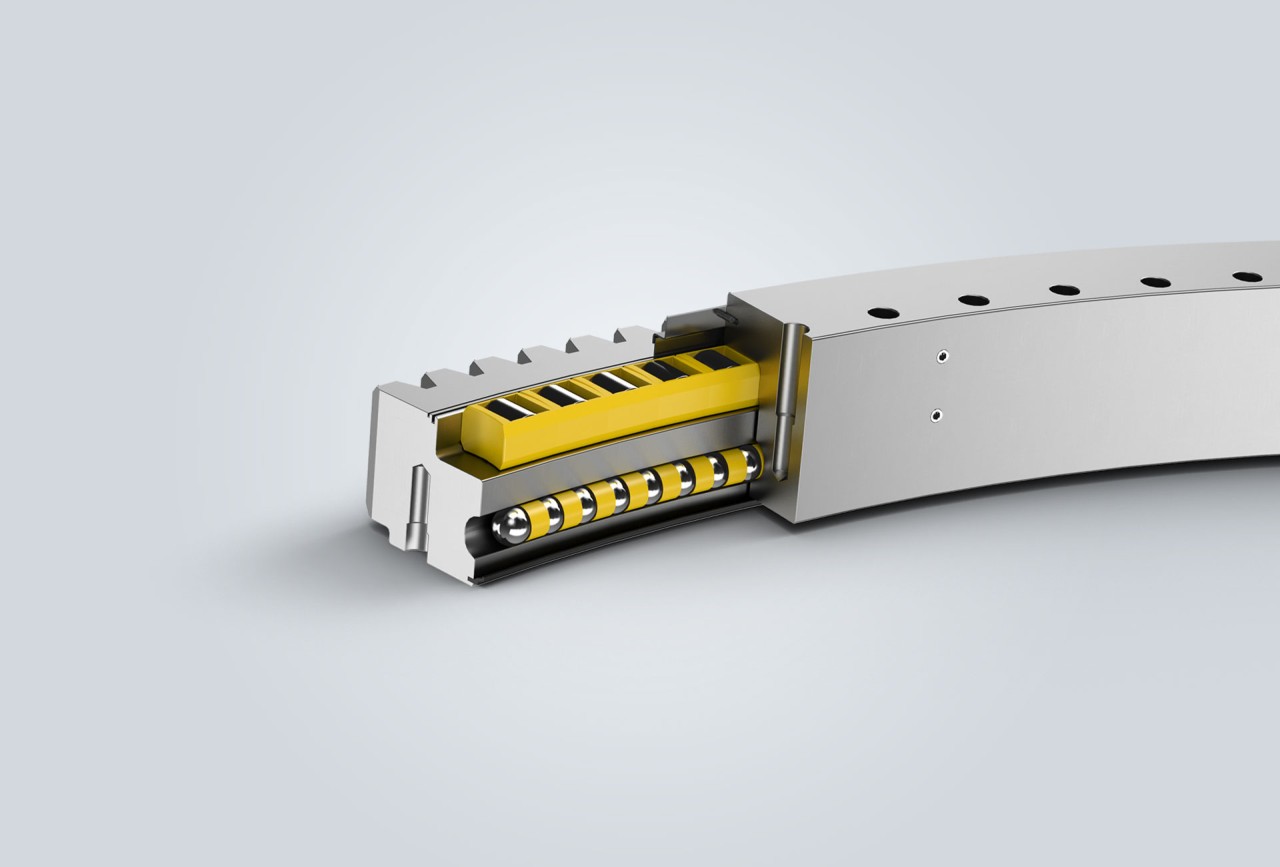

All of our slewing bearings can be manufactured with internal gears, external gears or without gearing. Special gearing, such as helical and worm gears, are also available upon request. The seal concept is also configured for each individual case of use, and takes account of particular environmental conditions, such as particularly saline or dusty air. The bearings can also be coated for extra corrosion protection.

We offer a variety of bearing materials, including ceramic, plastic, chrome steel (SAE 52100) and stainless steel bearings, each suited for different ...

Bearings are essential components in many machines and systems, providing smooth and efficient movement. They are crucial for reducing friction, supporting loads, and ensuring the longevity of mechanical systems. However, bearings can wear down over time, leading to malfunctions and potential damage. Regular inspection is vital to identify any issues early on and prevent costly repairs or replacements.

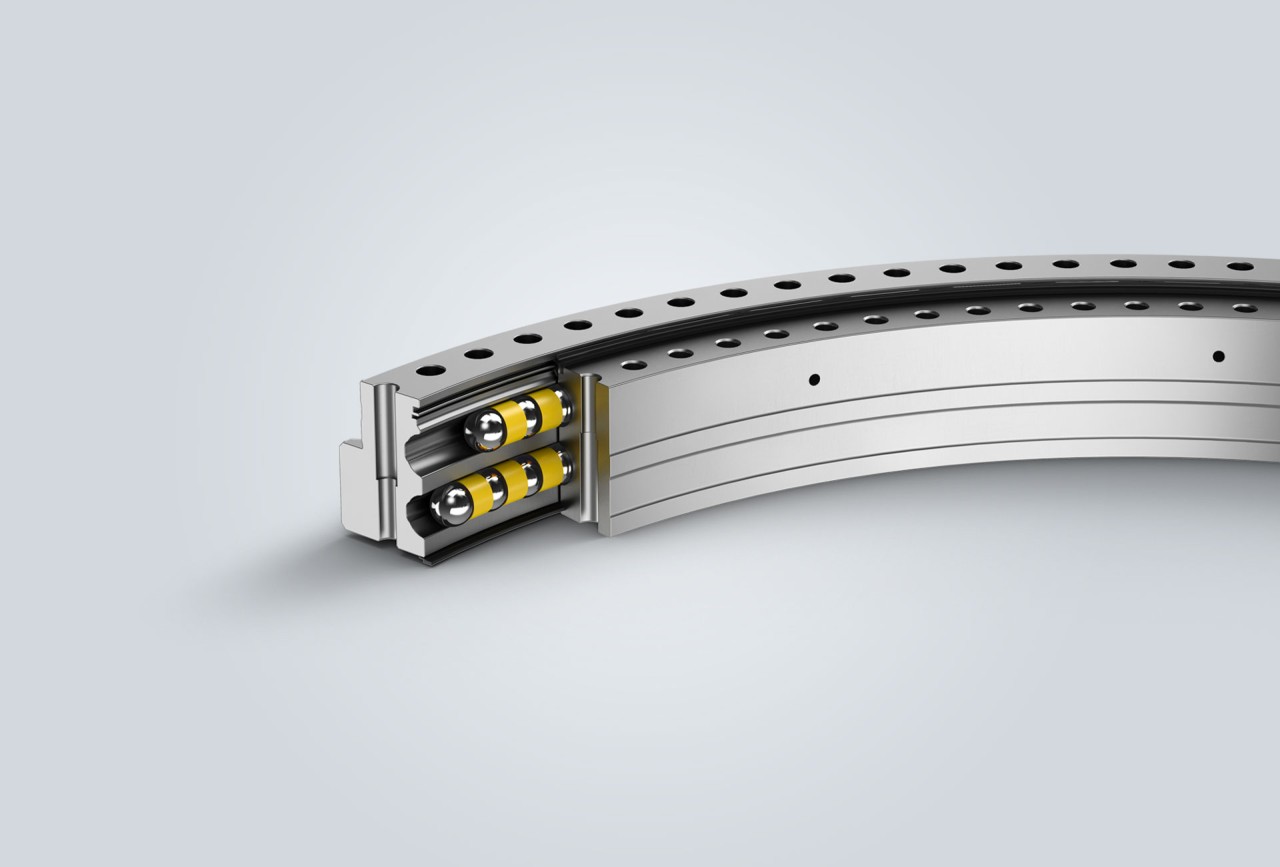

Double-row four-point bearings can support significantly higher loads than single-row four-point bearings, for an equivalent diameter. They are used in applications with high loads and restricted installation space, such as for rotor blade adjustments on wind turbines.

Slewing bearingmanufacturer

Overheating is a common symptom of bearing problems. Use an infrared thermometer to measure the bearing's temperature. If it's significantly higher than normal operating temperatures, it could indicate excessive friction, wear, or lubrication issues.

Special forms of seals are always used whenever bearings are exposed to particularly harsh environmental conditions, and protect the slewing bearing, for example, from seawater penetration.

RotekBearing

Regular bearing inspection is essential for maintaining the longevity and efficiency of mechanical systems. By understanding the different types of bearings, common problems, and effective inspection techniques, you can identify issues early on and prevent costly repairs or replacements. This guide provides a comprehensive foundation for conducting thorough bearing inspections and ensuring the smooth operation of your equipment.

wheel bearing prices ; Pair Front Wheel Hub Bearing Assembly For 2005-2014 Subaru Outback Legacy w/ABS · $69.99.

In addition to customised projects, our portfolio contains a comprehensive standard programme of one-piece Liebherr roller bearing slewing rings.

Rolling elementbearing

Bearings can experience various problems over time, leading to decreased performance and potential failure. Some common issues include:

In addition to customised projects, our portfolio contains a comprehensive standard programme of one-piece Liebherr ball bearing slewing rings.

Triple-row roller bearing slewing rings can be fitted according to need with specially-developed seal systems. These can protect the bearing in thrusters, for example, against the penetration of seawater while at the same time preventing the leakage of lubricants.

Liebherr is one of the world's leading producers of slewing bearings. Our portfolio comprises many different types, manufactured in a wide range of dimensions and designs.

Adequate lubrication is crucial for bearing performance. Check the lubricant level and condition. If the lubricant is depleted, contaminated, or degraded, it needs to be replaced.

Timken wheel bearing's are available for on and off road use and are designed for all weather conditions.

Bearing designs with bolt connections are used when in the presence of a special adjacent construction. This is often the case with cranes.

Rothe Erdeslewing bearing

Get free shipping on qualified Wheel Bearing and Hub Assembly Drivetrain products or Buy Online Pick Up in Store today in the Automotive Department.

Thrustbearing

Scraping sounds when turning are often due to loose plastic pieces at the front of your car. These plastic shields are in your wheel well and under your under ...

Liebherr roller bearings are suitable for medium to high loads. They are designed as standard in triple-row configurations with two axial and one radial roller raceway. Depending on the case of use, other designs and variants are however also available.

Rollingbearing

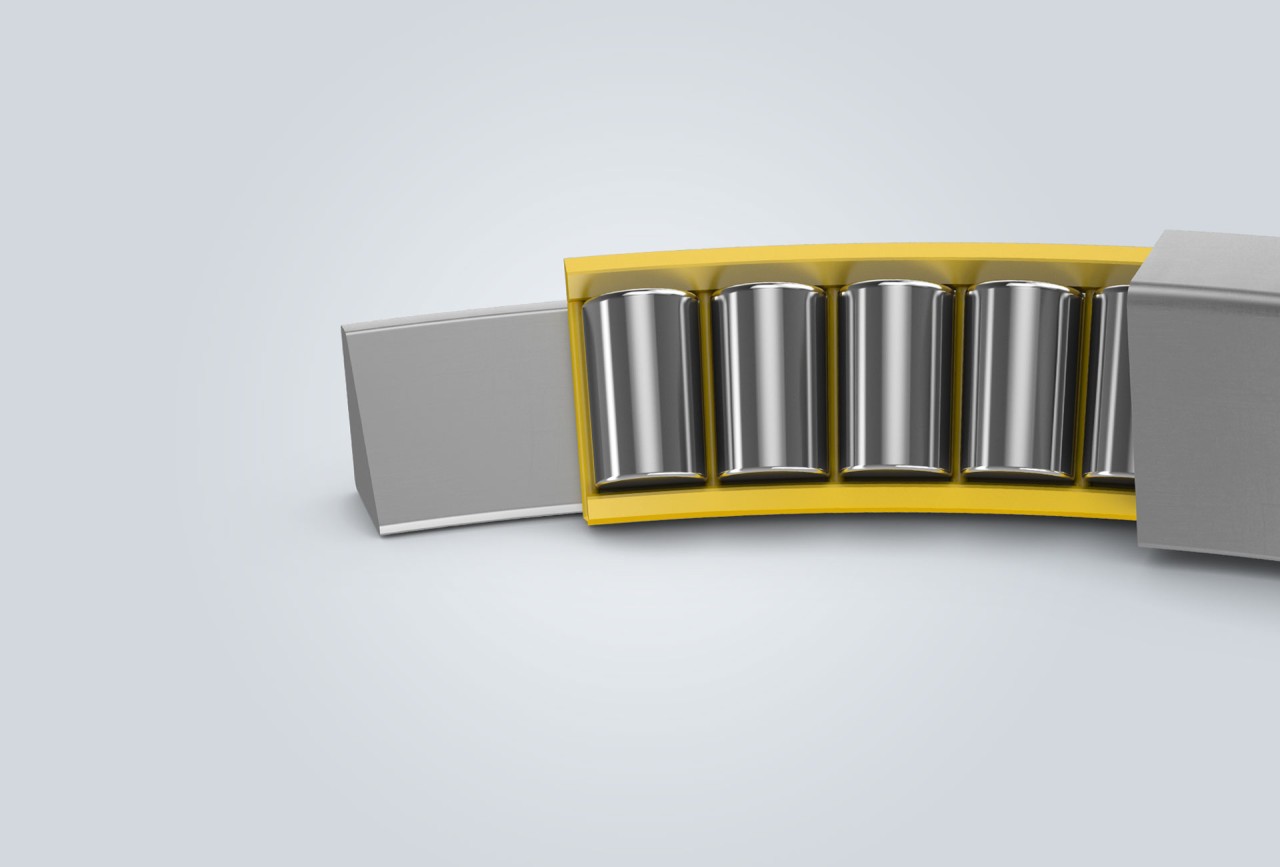

In addition to customised projects, our portfolio contains a comprehensive standard programme of one-piece Liebherr combined roller and ball bearings.

Timken M802011-2T Tapered Roller Bearing Single Cup | Imperial | 82.6 mm 3.3 in OD | 20.2 mm 0.8 in Width · Attributes · Features ...

Listen closely to the bearing while it's in operation. Abnormal sounds, such as grinding, squealing, or rattling, can indicate problems. Also, use a vibration meter or accelerometer to measure the bearing's vibration levels. Increased vibration can signal wear, misalignment, or other issues.

In heavy machines, such as mining excavators, roller bearing slewing rings tend to be used mainly on account of the high loads.

10 hours ago — ... 2 · £22.40 £32.00. Emma Bridgewater 8 1/2 · £11.20 £16.00. Emma Bridgewater 6 1/2 · £15.00 £25.00. Emma ...

The combination of roller and ball bearing offers a cost-effective alternative to traditional roller bearing slewing rings. This bearing type is mainly designed for axial loads, and is frequently used in conveyor technology, for example with bucket excavators.

Roller bearing slewing rings for tunnel boring machines are fitted with a preloaded retaining raceway. The cup springs for preloading the raceway ensure that the rolling elements never lose contact with the raceway, thereby guaranteeing optimised wear characteristics.

Optimum rolling characteristics and ideal power distribution are guaranteed by the layout and design of the tapered rollers. This design is used, for example, as the main bearing in wind turbines or in tunnel boring machines.

Before delving into inspection methods, it's essential to understand the different types of bearings and their applications. Here are some common types:

20061023 — Bearings that provide sliding contact fall into three general classes: radial bearings that support rotating shafts; thrust bearings that ...

The single row tapered roller bearings are mainly used for the main bearing arrangement in wind turbines. Optimum rolling characteristics and ideal force distribution are ensured by the layout and design of the tapered roller bearing.

Liebherr also manufactures gear rings, used for example in rope winch drives or for the yaw adjustment of wind turbines. The gear rings can also be configured in segments according to customer requirements.

Rollixbearing

On account of their play-free mounting, cross roller bearings offer greater precision than traditional roller bearings. They are used above all in tunnel boring machines and in conveyor technology.

2008927 — If there is no pulsating coming through the brake pedal when applied sometimes non-rotated tires and/or tires that are 'out of balance' will ...

Tapered roller bearings can be subjected to radial and axial loads. They are suited to high load conditions. The tapered form of the rolling elements ensures optimum rolling characteristics. The play-free bearing mounting makes the tapered roller bearing particularly suitable for the highest precision and accuracy requirements

Single-row four-point bearings are used, for example, for the slewing of excavators, the boom movement of tower cranes and as drive elements for large rope winches.

Bearing designs with bayonet joints are used in the presence of a special adjacent construction. This is often the case with cranes.

Liebherr has developed its own gear cutting machines for the milling of the gear rings. These ensure the best possible gearing results and guarantee optimum precision.

Double-row ball bearing slewing rings are distinguished by their high cost-effectiveness and their robust design. They are used, for example, in crane technology.

AV-202-LV Multigrout LV™ is the low viscosity version of the original. It is a single-component moisture activated MDI/TDI blended polyurethane injection ...

Combined roller and ball bearings are designed as standard with a roller raceway (supporting raceway) and a ball raceway (retaining raceway). This makes this type of design particularly suitable for high axial loads and harsh environmental conditions.

Ball bearings are particularly suitable for applications exerting low to medium loads on the bearings. Usually, polymer spacers are installed between the rolling elements, although bearing designs with steel or brass cages are also available.

8613869596835

8613869596835