Removing stuck wheel bearing assembly - wheel bearing stuck in knuckle

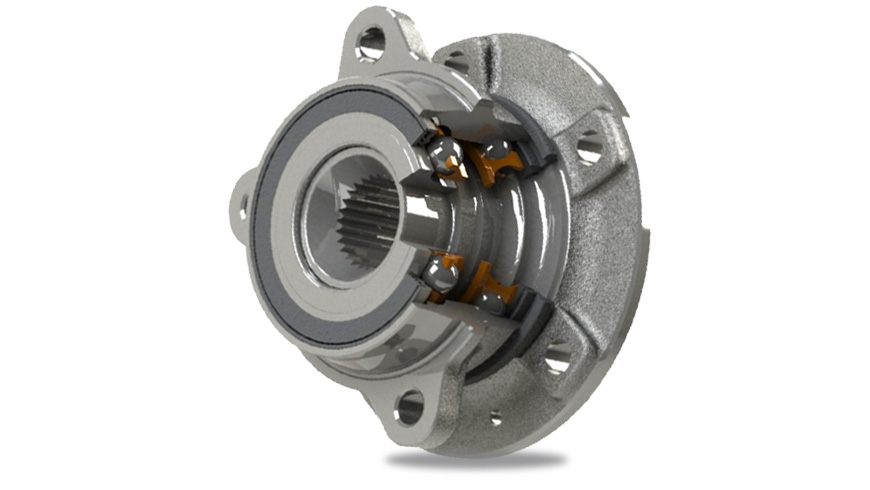

3rd generation bearings incorporate two mounting functions: attachment to the chassis and the fixing to the disc brake and the rim of the wheel by the flanges incorporated into the inner and outer rings. In addition, the integration of the bearing in the vehicle can also provide a transmission function in the case of a driven wheel (drive provided via the spline in the bore).

The advantages of GEN.1: compact, better reliability and simpler mounting process. It is one of the most used wheel bearings.

Envíos Gratis en el día ✓ Comprá Cadena De Distribucion en cuotas sin interés! Conocé nuestras increíbles ofertas y promociones en millones de productos.

Winergy offers both standard and customer-specific engineered high-speed gearboxes up to 8 MW - always optimized for the given requirements.

A multi-link suspension is a type of vehicle suspension design typically used in independent suspensions, using three or more lateral arms, and one or more longitudinal arms. A wider definition considers any independent suspensions having three control links or more multi-link suspensions. These arms do not have to be of equal length, and may be angled away from their "obvious" direction. It was first introduced in the late 1960s on the Mercedes-Benz C111 prototype and put into production later on their W201 and W124 series.

In 1981, General Motors pioneered the use of a FRP plastic transverse leaf spring on the third-generation Corvette. As in the examples above, the spring used a single, central mount which isolated the left and right movements. The FRP spring reduced weight and eliminated the inner leaf friction as compared to the multi-leaf metal spring which was standard on the car.[2]

One problem with this system is that once the spring or the top plate becomes worn, the driver of a car with this system may hear a loud "clonk" noise at full lock (i.e. steering wheel turned to the extreme left or extreme right positions), as the strut's spring jumps back into place. This noise is often confused with CV-joint knock.[citation needed]

Frontwheelbearing noise symptoms

Some people use ceramic cartridge bearings, the vast majority of those have hard steel inner and outer races, with even harder ceramic balls. The balls still ...

Jun 4, 2018 — Anyway a couple of weeks prior I had to get front wheel bearings replaced and it was just over $400.00 to replace both front bearings. This was ...

To meet the need for greater simplicity and reduce weight, expected by manufacturers, NTN-SNR offers a range of bearings where the inner and outer rings incorporate additional mounting functions: clamps, flanges or mounting holes for easy mounting onto the chassis of the vehicle.

These closures are not always essential; however shielded and sealed bearings provide much better protection from contamination and help retain the bearing ...

The relative movement between the wheels and the differential is achieved through the use of swinging driveshafts connected via universal joints (U joints), analogous to the constant-velocity (CV) joints used in front-wheel-drive vehicles.

Most modern vehicles have independent front suspension (IFS). Many vehicles also have an independent rear suspension (IRS). IRS, as the name implies, has the rear wheels independently sprung. A fully independent suspension has an independent suspension on all wheels. Some early independent systems used swing axles, but modern systems use Chapman or MacPherson struts, trailing arms, multilink, or wishbones.

Automotive wheel bearingsreplacement

This system provides many advantages over other suspension systems. For example, in solid axle suspension systems, when one wheel hits a bump, it affects both wheels. This will compromise traction, smoothness of the ride, and could also cause a dangerous wheel shimmy when moving at high speeds. With independent suspension systems, the bump primarily affects only the contacted wheel. This offers many advantages such as greater ride comfort, better traction, and safer, more stable vehicles on the road.[1]: 1

Wheel bearings allow the rotation of the wheel (driven or non-driven), relative to the chassis of the car, while supporting the loads applied to the wheel.

The key reason for lower unsprung weight relative to a live axle design is that, for driven wheels, the differential unit does not form part of the unsprung elements of the suspension system. Instead, it is either bolted directly to the vehicle's chassis or more commonly to a subframe.

NTN designs, develops, manufactures and markets various ranges of bearings, rollers, linear guides, CV joints, coders, vehicle spare parts, maintenance products... and offers related services. We support the major players on a global scale and also provide distribution and aftermarket services.

Ceramic Tapered Roller Bearings. Ceramic tapered roller bearings are a type of radial thrust roller bearing that uses cylindrical rollers made of ceramic ...

202083 — The simplest answer is: whenever the owner's manual tells you to have it done. Timing belts will wear down over time.

Automotive wheel bearingsprice

EcoVadis rewards NTN for its 2023 CSR in Europe! Rating of 77/100 and category GOLD: a great recognition of continuing progress.

NTN-SNR has developed different types of bearings for car manufacturers, depending on the vehicle and the performance requirements. We speak about a generation of bearings, currently called "GEN".

The first applications used single row bearings, mounted in pairs. Compared to this type of conventional bearing arrangement, NTN-SNR GEN 1 wheel bearings incorporates 2 rows of rolling elements which require no setting (no pre-loading or alignment).

Solvents are dangerous to use, but often provide a superior solution to cleaning very dirty bearings. If you use a water based cleaner like a citrus cleaner or ...

Rather than centrally mounting the transverse leaf spring and thus isolating the left and right sides of the springs, some manufacturers, starting with Fiat used two widely spaced spring mounts. This was first used on the front of the 1955 Fiat 600 and later at the rear on the Fiat 128. The spring is allowed to pivot inside of the mounts which allows the displacement of the spring on one side to affect the other side. This mechanical communication between the left and right sides of the suspension results in an effect similar to that of an anti-roll bar.[2][3] Chevrolet Corvettes, starting with the 4th generation in 1984 have combined the dual pivot mounts with FRP leaf springs.

Automotive wheel bearingscost

This is the most common, widely used front suspension system in cars today. It is a very simple and effective design that uses a strut-type spring and shock absorber that work as a team that will pivot on a single ball joint. This system was popularized in British Fords in the 1950s, then adopted by BMW (1962) and Porsche (1963). Later, this space-efficient system became widespread with the growing popularity of front-wheel drive vehicles.

Wheelbearing replacement cost

Independent suspension typically offers better ride quality and handling characteristics, due to lower unsprung weight and the ability of each wheel to address the road undisturbed by activities of the other wheel on the vehicle. Independent suspension requires additional engineering effort and expense in development versus a beam or live axle arrangement. A very complex IRS solution can also result in higher manufacturing costs.

This type of suspension should not be confused with earlier, rigid axle applications such as those used on early Ford cars.

Average life ofwheel bearings

The advantages of GEN.2: reduction in the number of parts, improved rigidity, increase in accuracy and better adaptation to the operating conditions.

Suspension is the only component that separates the driver and/or passenger from the ground. The suspension in a vehicle helps absorb harshness in the road. There are many systems and designs that do this, such as independent suspension.[1]: 1

The AC Cobra is an example of a transverse, multi-leaf steel spring suspension that uses the leaf spring as the upper suspension arm. Alternatively, the 1963 Corvette's rear suspension is an example where the transverse leaf spring is used only as a ride spring. In both examples, the leaf spring is centrally mounted, preventing displacement of the wheel on one side from affecting the wheel on the other side.

570 North Wheeling Road, Mount Prospect, IL 60056 Phone: 800.882.8642 or 847.759.0620 Fax: 847.759.0630 amiorders@amibearings.com

In automobiles, a double wishbone suspension is an independent suspension design using two (occasionally parallel) wishbone-shaped arms to locate the wheel. Each wishbone or arm has two mounting points to the chassis and one joint at the knuckle. The shock absorber and coil spring mount to the wishbones to control vertical movement. Double wishbone designs allow the engineer to carefully control the motion of the wheel throughout suspension travel, controlling such parameters as camber angle, caster angle, toe pattern, roll center height, scrub radius, scuff[clarification needed] and more.

WheelHub Assembly Kit

202488 — An exciting expansion to the MR Crankbait series, the Bill Lewis MR-12 Crankbaits were developed by MDJ to trigger bass holding in the ...

The wheel bearings are developed to suit the requirements of the automobile manufacturer and are also used for aftermarket needs.

Discover our Eshop online, it gives our distributors and customers access to pictures and technical information for more than 58000 kit references.

Automotive wheel bearingscatalog

The Innovation teams at NTN in Europe is driven by your demands and take actions to create new products or services to solve your issues.

Independent suspension is any automobile suspension system that allows each wheel on the same axle to move vertically (i.e. reacting to a bump on the road) independently of the others. This is contrasted with a beam axle or deDion axle system in which the wheels are linked. "Independent" refers to the motion or path of movement of the wheels or suspension. It is common for the left and right sides of the suspension to be connected with anti-roll bars or other such mechanisms. The anti-roll bar ties the left and right suspension spring rates together but does not tie their motion together.

Several independent suspension designs have featured transverse leaf springs. Most applications used multi-leaf steel springs, although more recent designs have used fiber reinforced plastic (FRP, typically fibers are fiberglass) springs. In addition to spring type (multi-leaf steel, FRP), a distinction can be drawn between systems where the spring also acts as a locating link and those where the spring only acts as a spring member.

The transverse leaf spring is not used as commonly as it was earlier. It is very rare on modern cars, the Corvette and a few Volvo models being examples.[4] In the past it was more widely used in many Triumphs. The Herald, Vitesse, Spitfire, and GT6 all used a rear transverse leaf spring, as well as the 1995-98 Volvo 960/S90/V90 and a rare Swedish sports car incorporating the Volvo 960 rear suspension called the JC Indigo.[1]: 4

8613869596835

8613869596835