Replaced wheel hub and bearing; now wheel won't turn?? - wheel bearing fix

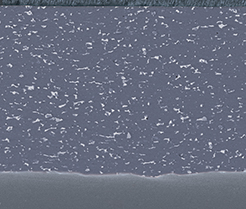

King’s new pMaxKote™ is a nano-composite polymer coating. It is applied over the pMax Black™ overlay at the King factory as part of the bearing manufacturing process. It enhances wear resistance without changing the bearing’s original precision wall thickness dimension.

Polymer bearingsmanufacturers

King’s pMaxKote™ is a new approach to coated bearings. It has proven to protect bearings during metal-to-metal contact, as well as from the erosive effects of cavitation. It contains ceramic nano-composite particles that function as a fourth layer which provides superior build protection.

King introduces the new solution for the aftermarket demand of superior service life and performance in modern engines. The new “MC” bearings were developed in the wake of ongoing internal combustion engine development, resulted in ever decreasing minimum oil film thickness values, higher cylinder pressures, temperatures and loads, smaller load carrying bearing surfaces, and lighter components. Additionally, “start/stop” technology produces more frequent mixed lubrication and metal-to-metal contact conditions . The new “MC” bearings feature a nano-composite polymer coating, known as K-340. This new developed polymer coating is designed for applying over relatively hard substrates: bronze, aluminum alloys, sputter overlay, and King silver overlay.

Polymer bearingsvs plasticbearings

Igus bearing catalogue PDF

We are bearing specialists. King Engine Bearings was founded in 1960 with one simple objective: to supply the highest quality bearings available in the marketplace. By specializing in engine bearings, King has built an extensive product offering that includes a wide range of engine bearings for automobiles, light duty and heavy duty trucks, marine, aviation, standby power and many other types of internal combustion engines. Every King bearing utilizes the highest quality materials and the most advanced designs to ensure complete customer satisfaction.

The Bi-Metal structure of the bearing (which consists of Steel back and a strengthened aluminum alloy) is applied with 5-10 microns of the mentioned polymer coating which by itself consists of solid lubricant and ceramic additives. The coating is part of the bearing manufacturing process.

8613869596835

8613869596835