ROLLERS & WHEELS - guide wheels

Dunlop & the flying device are trademarks of Sumitomo Rubber Group and are used under license by BTL-UK LTD. MEDWAY, MSK-MEDICAL, TC OIL-SEALS & MEGACHAIN are registered trademarks of BTL-UK LTD

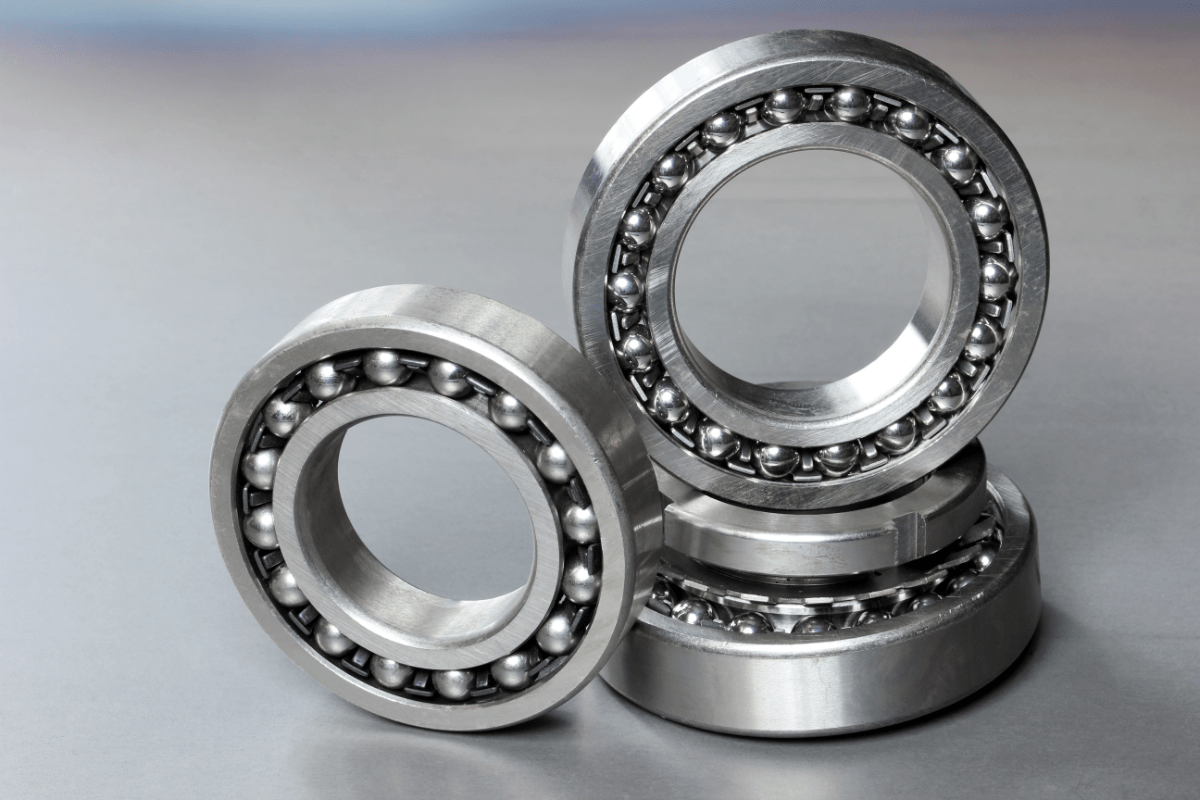

Heat during operation is generated through a build up of friction – an issue that ball bearings are specifically designed to avoid. Above usual levels of heat are, therefore, a common sign of friction building up between the bearing surfaces and should be addressed quickly before it causes overheating and damage. Excess heat can have a detrimental effect on other components in your system if it is not addressed promptly.

In this article, we discuss the main early warning signs to look out for that could indicate an emerging fault with your bearings.

A good ball bearing will be designed to minimise vibrations during operation, with a smooth transfer of motion and kinetic energy. Vibrations, therefore, can be a sign of a problem with your bearings. For example, if the ball bearing is not properly aligned or is damaged or worn, it will start to vibrate unusually during operation, even at its specified speed and load.

FDC 3/6405 FDC PART 1 OF 3 SECURITY..SPECIAL SECURITY INSTRUCTIONS FOR UNMANNED AIRCRAFT SYSTEM (UAS) OPERATIONS WITHIN AND IN THE VICINITY OF AIRSPACE OVERLYING THE TERRITORIAL AND NAVIGABLE WATERS OF THE UNITED STATES OF AMERICA (USA). PURSUANT TO 49 USC SECTION 40103(B)(3), THE FAA CLASSIFIES THE AIRSPACE DEFINED IN THIS NOTAM AND IN FURTHER DETAIL BY THE FAA WEBSITE IDENTIFIED BELOW AS 'NATIONAL DEFENSE AIRSPACE'. OPERATORS WHO DO NOT COMPLY WITH THE FOLLOWING PROCEDURES MAY FACE THE FOLLOWING ENFORCEMENT ACTIONS: THE UNITED STATES GOVERNMENT MAY PURSUE CRIMINAL CHARGES, INCLUDING CHARGES UNDER 49 USC SECTION 46307; AND THE FAA MAY TAKE ADMINISTRATIVE ACTION, INCLUDING IMPOSING CIVIL PENALTIES AND REVOKING FAA CERTIFICATES OR AUTHORIZATIONS TO OPERATE UNDER TITLE 49 USC SECTIONS 44709 AND 46301. IN ADDITION, PURSUANT TO 10 USC SECTION 130I, THE DEPARTMENT OF DEFENSE (DOD) MAY TAKE SECURITY ACTION THAT RESULTS IN THE INTERFERENCE, DISRUPTION, SEIZURE, DAMAGING, OR DESTRUCTION OF UNMANNED AIRCRAFT CONSIDERED TO POSE A SAFETY OR SECURITY THREAT TO PROTECTED DOD ASSETS. 2305201400-2505201400 END PART 1 OF 3 FDC 3/6405 FDC PART 2 OF 3 SECURITY..SPECIAL SECURITY INSTRUCTIONS FOR UNMANNED PURSUANT TO 14 CFR SECTION 99.7, SPECIAL SECURITY INSTRUCTIONS (SSI), ALL UNMANNED AIRCRAFT ARE PROHIBITED FROM FLYING WITHIN A STAND-OFF DISTANCE OF 3000FT LATERALLY AND 1000FT ABOVE ANY U.S. NAVY (USN) VESSEL OPERATING, TRANSITING, OR AT PORT WITHIN THE TERRITORIAL WATERS AND/OR NAVIGABLE WATERS OF THE USA. THE AIRSPACE IN WHICH UAS OPERATIONS MUST COMPLY WITH THIS SSI IS DEFINED AS THE AIRSPACE, SFC-2000FT MSL, ABOVE THE TERRITORIAL AND NAVIGABLE WATERS OF THE USA, INCLUDING PORTS, ANCHORAGES AND ADJACENT LAND. THE TERRITORIAL WATERS OVER WHICH THIS SSI APPLIES ARE VISUALLY DEPICTED AND GEOSPATIALLY DEFINED ON THE FOLLOWING FAA WEBSITE: HTTPS://UDDS-FAA.OPENDATA.ARCGIS.COM. NAVIGABLE WATERS OF THE USA ARE DEFINED BY 33 CFR PART 329. ADDITIONAL SECURITY-RELATED UAS RESTRICTIONS ARE DEPICTED ON HTTPS://UDDS-FAA.OPENDATA.ARCGIS.COM. UAS OPERATORS NEEDING TO OPERATE IN THE DEFINED AIRSPACE IN CLOSE PROXIMITY TO USN VESSELS OPERATING IN TERRITORIAL AND NAVIGABLE WATERS OF THE USA FOR OVERRIDING REASONS OF PUBLIC INTEREST OR NECESSITY (SUCH AS IN 2305201400-2505201400 END PART 2 OF 3 FDC 3/6405 FDC PART 3 OF 3 SECURITY..SPECIAL SECURITY INSTRUCTIONS FOR UNMANNED DIRECT SUPPORT OF AN ACTIVE NATIONAL DEFENSE, HOMELAND SECURITY, LAW ENFORCEMENT, FIREFIGHTING, SEARCH AND RESCUE, OR DISASTER RESPONSE MISSION; OR COMMERCIAL ACTIVITY) MUST COORDINATE AND OBTAIN ADVANCE AUTHORIZATION FROM THE APPROPRIATE DOD/USN POINT OF CONTACT IDENTIFIED IN THE FOLLOWING FAA WEBSITE: HTTPS://UDDS-FAA.OPENDATA.ARCGIS.COM. OPERATORS UNABLE TO SUCCESSFULLY COORDINATE WITH THESE DOD OR USN POINTS OF CONTACT MAY CONTACT THE FAA SYSTEM OPERATIONS SUPPORT CENTER (SOSC) AT (202) 267-8276 FOR FURTHER ASSISTANCE. IF YOU HAVE GENERAL QUESTIONS REGARDING UAS OPERATIONS, PLEASE REFER TO WWW.FAA.GOV/UAS/CONTACT; OR CONTACT THE FAA VIA EMAIL AT UASHELP@FAA.GOV OR PHONE AT (844) FLY-MY-UA. IF YOU HAVE QUESTIONS REGARDING THIS UAS-SPECIFIC SSI, PLEASE REFER TO THE FOLLOWING FAA WEBSITE: HTTPS://UDDS-FAA.OPENDATA.ARCGIS.COM; OR CONTACT THE FAA SOSC AT (202) 267-8276. 2305201400-2505201400 END PART 3 OF 3

One of the tell-tale symptoms of a failing bearing is excessive or unusual noise during operation. In particular, a growling, squealing, or humming noise could indicate insufficient lubrication, poor alignment, or the early stages of a mechanical fault.

Although high quality ball bearings are generally durable components – especially when purchased through a reputable supplier and produced by a world leading brand, such as Dunlop – these components can and do develop faults through regular use. Recognising the first signs or symptoms of ‘bad’ ball bearings will enable rapid repair or replacement before excess friction and waste heat leads to mechanical damage or premature failure in your application.

BTL-UK LTD is proud to be a committed European manufacturer of Bearings, Power Transmission and linkage products, as well as high quality sub-contract precision engineered turned, milled and gear-cut components. We believe in the future of European manufacturing and will continue to focus and further enhance the requirements and expectations of our customers globally.

At BTL-UK, we supply a wide range of ball bearings for manufacturing and industrial applications, and are an approved supplier for Dunlop, with an extensive selection of bearings in stock for immediate dispatch from our UK distribution centre. To find out more about our product availability, please click here to download our free bearings catalogue, or either get in touch via are website or call 01233 663340 today to discuss your project requirements with one of our knowledgeable team.

Even a small lubricant leak is a red flag of a potential problem, often the result of a damaged seal on a bearing allowing lubricating oil to leak out from inside the component itself. The immediate result is less protection for the bearing and an increased risk of further wear and tear over time. A lubricant leak could progress into additional symptoms, such as excessive heat, vibration, and noise, and the issue should be addressed as quickly as possible.

Spherical ball bearings are intended to rotate in all directions, accommodating both radial and axial loads. Rough or sluggish rotational movement may be the sign of wear and tear or physical damage, so if you notice a change in the range of movement when using your machinery, we recommend inspecting each component carefully to identify any potential issues.

8613869596835

8613869596835