Seal Concept GmbH - R33 PTFE Radial Shaft Seal Rings - radial seal

Whether you're working with a handheld thermal imaging camera, acoustic imaging camera, or optical gas imaging (OGI) camera, the best solution for organizing and managing condition monitoring programs is FLIR Thermal Studio Suite. This subscription software offers the organizational features and advanced processing needed for predictive maintenance on critical components, system troubleshooting, and increased productivity.

Condition monitoringsystem

Continuous monitoring with fixed thermal monitoring cameras can be an easy way to integrate condition monitoring into your application. Learn more

Condition monitoringequipment

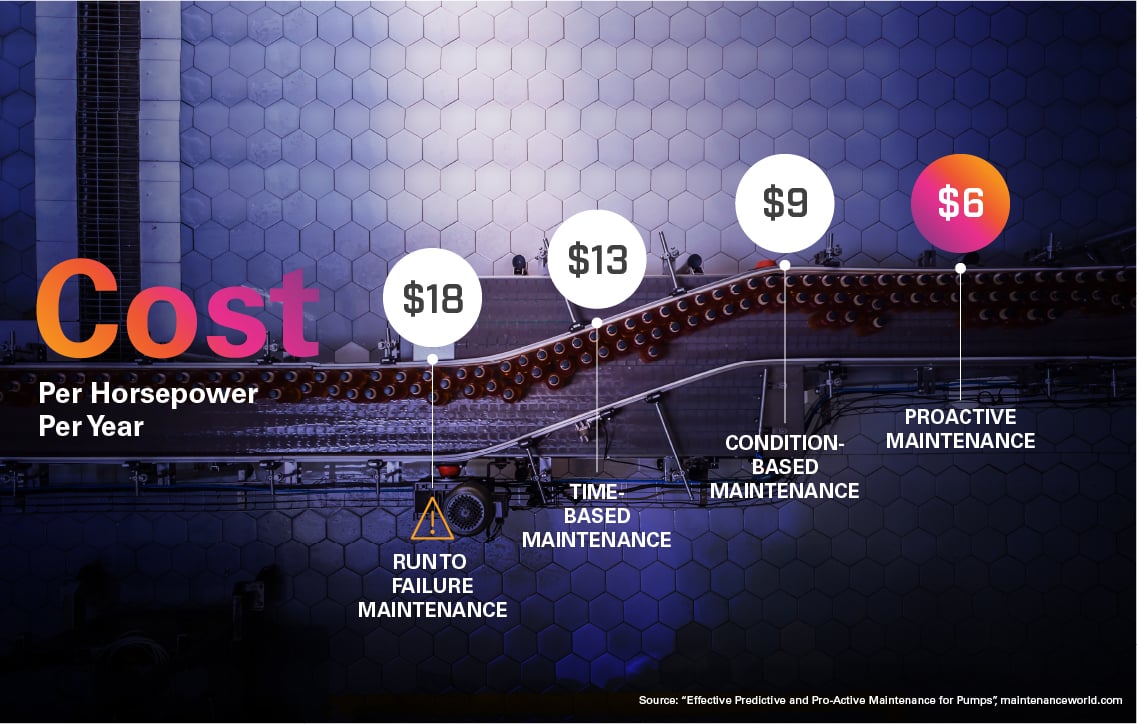

Or—get proactive. Build a cost-effective condition monitoring program to investigate the root causes of equipment failure. This can include:

FLIR Thermal Studio Pro is a desktop software offering batch image processing, advanced image analysis, and access to FLIR Route Creator: a feature that lets users create their own inspection map and download it to a FLIR camera with Inspection Route enabled.

By regularly collecting this data, your team can easily pinpoint the optimal time for maintenance and even improve equipment, so failures don't happen again.

Condition monitoringtechniques

Condition monitoringexamples

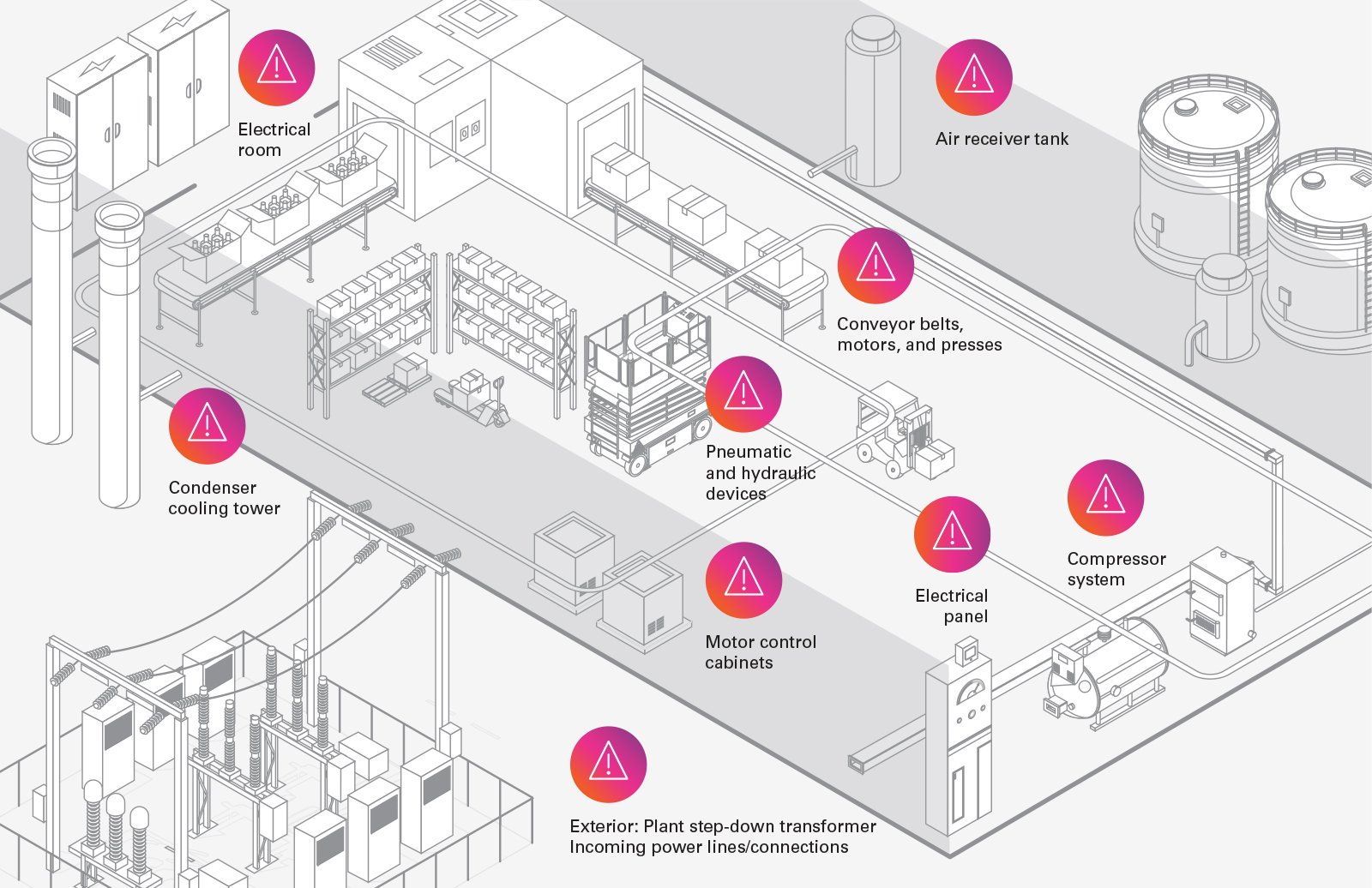

Check out this representation of a factory floor with locations where facilities maintenance engineers can effectively perform condition monitoring using FLIR thermal, acoustic, and Test & Measurement products.

FLIR offers a range of handheld and fixed monitoring tools as well as inspection software—all designed to make condition monitoring more efficient and help companies maximize their uptime.

Condition Monitoringppt

When paired with the FLIR IgniteTM cloud service for direct image back up, FLIR Thermal Studio software ensures accurate data collection that helps predictive maintenance crews spot problems before they cause critical failures.

Condition monitoring is about more than maintaining equipment: it's a critical task that can ensure power keeps flowing, machines keep working, equipment lasts longer, and companies avoid breakdowns.

8613869596835

8613869596835