Sealing Solutions for Aerospace - Hutchinson - PSS - seals aerospace

The hub is responsible for connecting the wheel to the axle of the vehicle. It also houses the wheel bearings. This metal casing typically comes in the shape of a disc with a slightly protruding midsection containing several studs. There’s also a hole in the middle for the bearing.

Hubs can become stressed when the bearings they house fail. Since a worn out hub can make your vehicle extremely difficult to handle, you’ll want to replace your hubs as soon as possible whenever this happens.

You’ll normally hear a rattling sound for some time before this occurs—so you’ll get plenty of warning. Still, it’s vital to replace a worn-out wheel bearing as soon as possible to prevent performance issues and more costly mechanical problems.

Drive shafts can become damaged in several ways, including when the wheel bearings or hub in your vehicle have begun to wear down. In this case, you’ll probably notice excessive vibrations when accelerating or braking, and might hear a knocking noise.

Wheelhubbearing

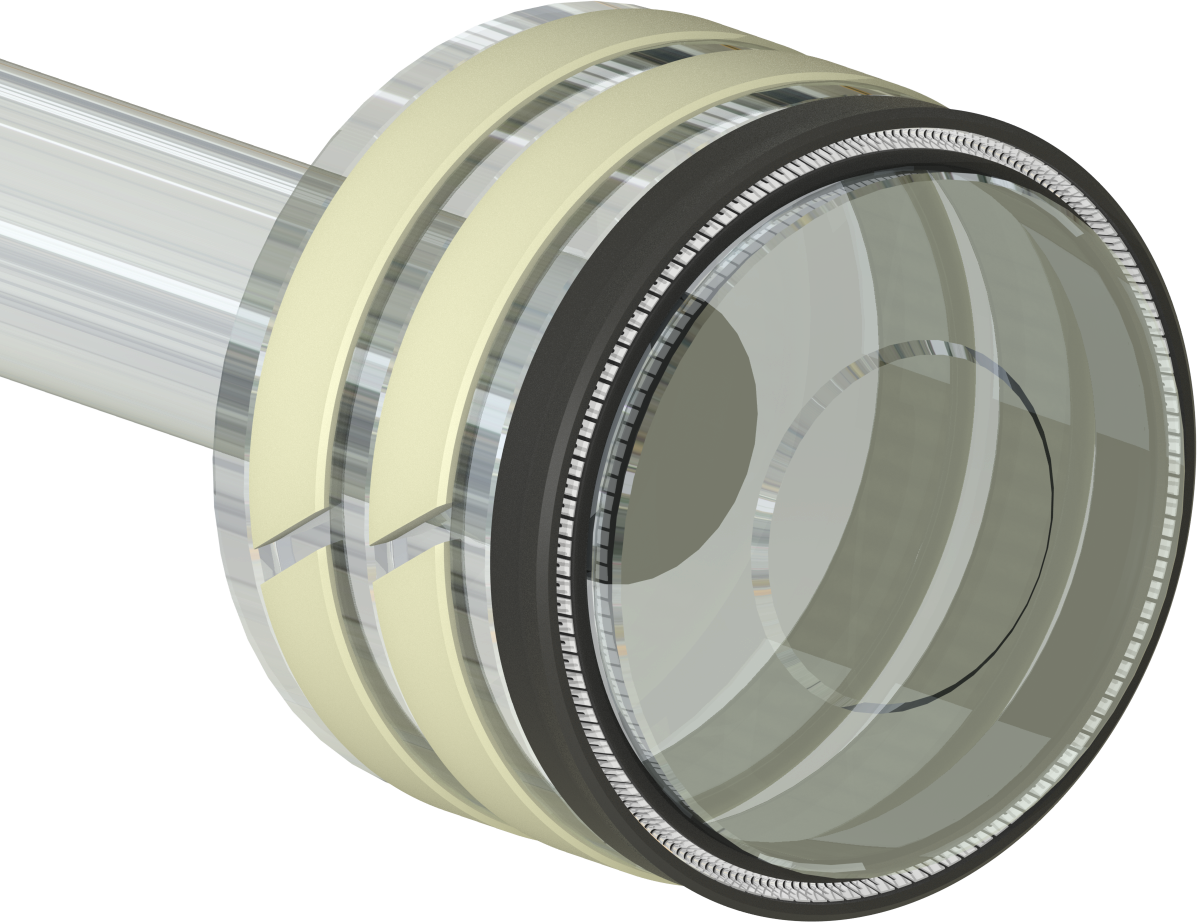

The seals that sit between your bearings and the drive shaft of your vehicle exist to keep out substances and materials that could cause the bearings to wear out faster—dirt, water, and other debris from the road being some of the most common.

The major components of your wheel bearing and hub assembly are the bearings, hub, rotor, seal, and the drive shaft itself. Each of these parts must work in concert with the others to manage the forces that braking and cornering place on your vehicle during regular use.

wheelbearing中文

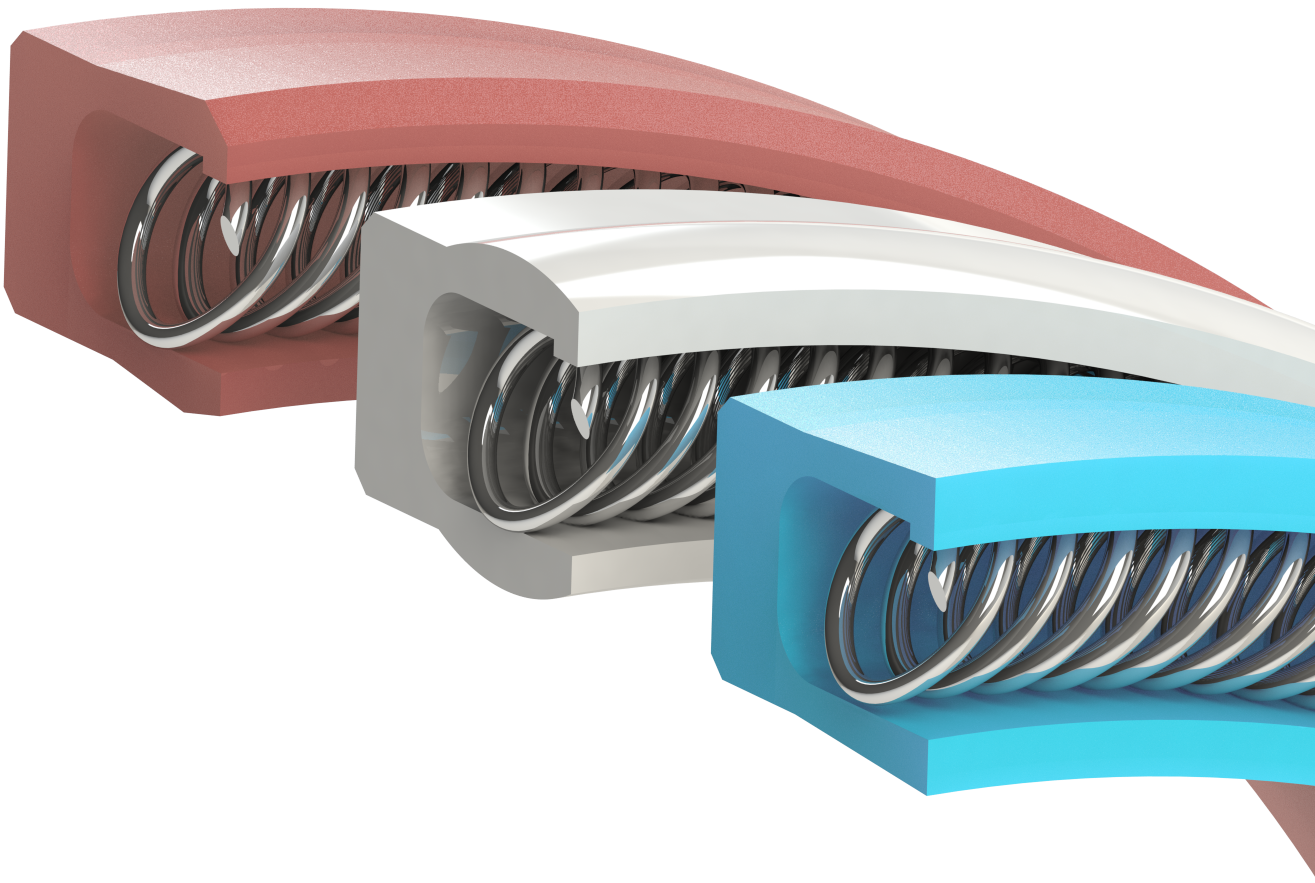

Commonly, O-Rings fail due to extrusion into hardware clearance gaps, creating a nibbling effect that quickly degrades the seal leading to premature failure. Backups are used in these situations and are designed to fit between the O-Ring and clearance gap, thereby preventing extrusion and increasing the pressure rating of the O-Ring. Backup ring materials are made of extrusion resistant materials such as Eclipse ET (PTFE), Eclipse EN (nylon), Eclipse EP (PEEK) and Eclipse EH (Thermoplastic Elastomer). Eclipse offers solid and split configurations per dash number standards and also designs manufactures custom backups.

Spiral backups are a coiled configuration making use of overlapping sections. They can be installed in solid pocket grooves and offer improved resistance to O-Ring nibbling. Most often ordered in PTFE material to O-Ring dash size MS28782 standards.

Wheel bearing

The drive shaft of your vehicle is responsible for moving torque from the engine into the wheels, facilitating movement. The transmission sends kinetic energy from the engine through the shaft into the differential, rotating the axle shafts (which are connected to the wheel hubs on each side of the car).

Split backups are manufactured the same as solid backups, but have an angled cut in one location to allow installation in solid pocket grooves. This is the preferred configuration for any high modulus (i.e. PEEK, Nylon) backup ring. Back-ups to Military standards as well as Aerospace (rod and piston) standards are available.

Wheelhub assembly

Below, we’ve put together a diagram showing the different parts of wheel bearings and hubs, along with a description of each main component. Ready? Then let’s dive in.

Because they’re absorbing so much energy on such a frequent basis, brake rotors wear out regularly and need to be replaced. However, driving on worn-out brake rotors can feel very similar to driving on a dead wheel hub. You may experience a wobbling feeling while braking—however, in the case of a dead hub or worn-out bearings, this may also be accompanied by a slight pull to the side with the damaged component. Take your vehicle to a mechanic to determine the exact cause of the problem and find out what part needs to be replaced.

Carparts

The rotors on your vehicle help you brake while driving. Pressing the brakes in your vehicle causes the calipers to squeeze your brake pads against the rotors, creating friction that eventually causes the wheels to stop spinning and bring your car to a halt.

Bearings generally come in the form of balls or tapers within a metal ring that rides on the shaft of the axle and fits into the hub. Due to the nature of the forces placed on wheel bearings, they are more prone to failure than many of the other components we’ll discuss here.

The purpose of wheel bearings is to help the wheels of your vehicle turn with minimal friction when torque is sent to the wheels from the engine. When a wheel bearing begins to wear out, it becomes more difficult for the corresponding wheel to rotate, which can eventually cause handling problems and even permanent suspension damage.

Solid (non-split) back-ups are specified when installation is not an issue, that is, when a groove other than a solid pocket O-Ring groove is available. In some instances solid backups can be stretched into these grooves depending on the specific material properties and installation diameter. Back-ups to Military standards as well as Aerospace (rod and piston) standards are available.

Below, you’ll see a diagram showing the location of the wheel bearings and hub assemblies on a typical car. The hub, bearing, and rotor on each wheel is connected via a seal to the drive shaft (through the axle shaft). The construction of all wheel bearing and hub assemblies will look similar even when comparing large to small vehicles. For example, a Ford F-150 wheel bearing will be bigger, but look similar to a Ford Explorer wheel bearing.

wheelbearing是什么

However, these seals also keep the grease used to lubricate your bearings inside the hub assembly. This grease is vital for prolonging the lifespan of your hub and bearings, so these seals need to be checked often and replaced if they have deteriorated.

Wheel bearings and hub assemblies play a vital role in the performance of your vehicle, but they’re easy to overlook. After all, these parts are small and hard to see at a glance—so they don’t always get much thought. Still, you need to understand what they do and buy high-quality replacement parts when the wheel bearings in your vehicle wear out if you want to keep it running properly.

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!

Understanding where your wheel bearings, hubs, and related components are—and how they function—is vital for keeping your vehicle in proper working order. Use what you’ve learned above to keep a closer eye on these important parts and replace them with high-quality aftermarket components when required.

8613869596835

8613869596835