Shaft Alignment Lasers & Tools - machine alignment laser

Detroit Axlewheelbearings review

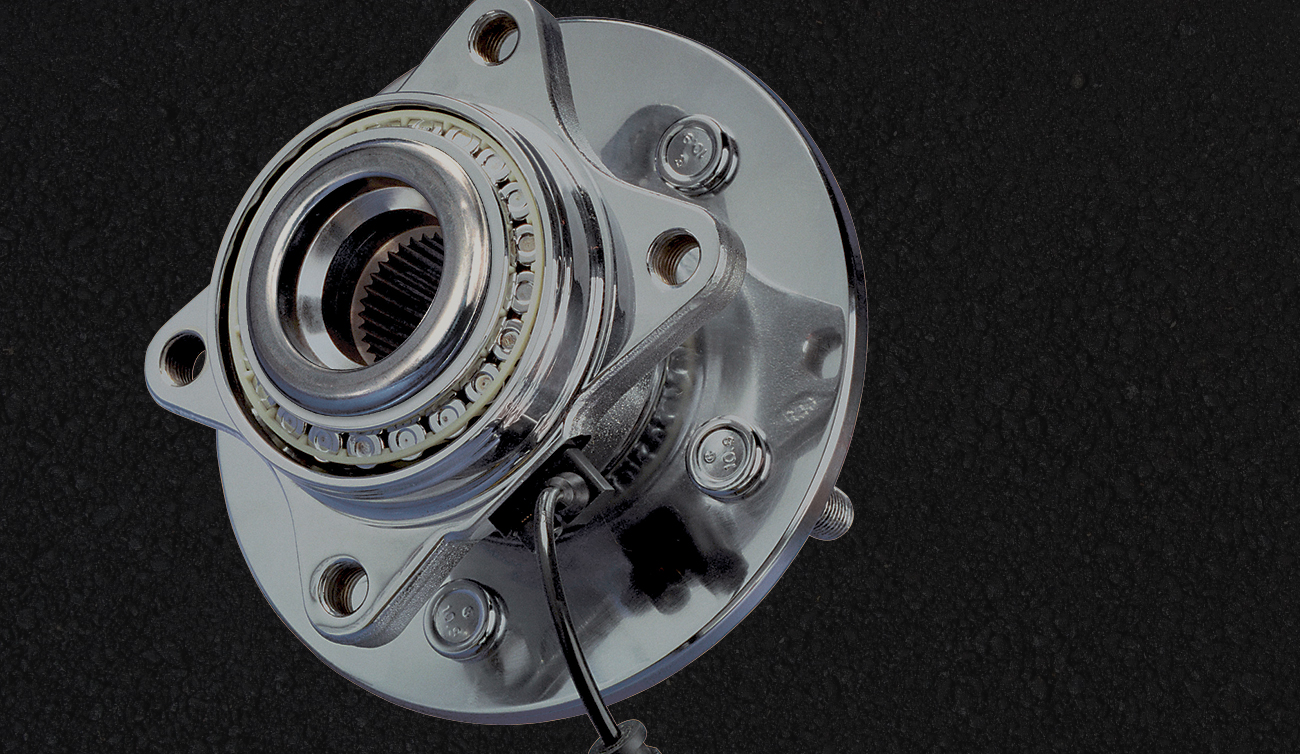

The wheel bearing with two central ball bearings provides a high level of precision and smooth running performance. It also provides an effective seal while meeting demanding load capacity requirements. Positive locking is used to encapsulate the ball bearings with the wheel centre. The central ball bearings are provided with two sealing caps (slipping sealing, so-called 2RS bearings) as standard. The ball bearings are lubricated using long-life grease and are maintenance-free under normal application conditions. The additional synthetic ball bearing cover provides protection for both the wheel hub and the thread. When the wheel is fitted in swivel and fixed brackets, no flanged bushes are required, unlike for conventional wheel bearings with ball bearings that are pressed in.

2018329 — The noise sounded like metal scraping on metal, or scraping on a lumpy rough surface. It was not a smooth squeal, but a clunky crunchy scraping sound.

wheelbearing坏了

The plain bore is a simple, cost-effective and resilient wheel bearing. It is also corrosion-resistant and maintenance-free under normal conditions. Plain bores are mainly used for light duty and transport equipment castors, which are only moved infrequently and at slow speeds. Nylon plain bore sockets are used for wheels with tubular steel hubs. Plain bores may run hot at high speeds and under high loads. Cast iron wheels with plain bores must be lubricated on a regular basis.

Description. Outdoor floodlight for commercial signs, a classical European design with asymmetric light distribution. The floodlight can be mounted on the ...

The wheel bearing with grooved ball bearing (also called a precision ball bearing) meets high standards in terms of load capacity, rolling characteristics (even at high speeds) and resistance to environmental factors. Grooved ball bearings have the lowest level of bearing clearance, and are mainly used in technically-demanding transport unit castors and heavy-duty castors. A cover cap provides protection against dust (non-rubbing seal, also known as a Z bearing). Ball bearings can be installed with one or two sealing caps (slipping sealing, also known as an RS or 2RS bearing) for special requirements. Wheel bearings with ball bearings sealed on both sides (2RS) must not be lubricated to avoid damage to the ball bearing. Grooved ball bearings are lubricated using long-life grease and are maintenance-free under normal application conditions. Two ball bearings are installed in the hub as standard. A spacer sleeve is used to maintain the distance between the inner race of the ball bearing. This means that the wheel can be clamped axially into a bracket (exception: roller for pallet trucks). In addition to the standard version, ball bearings are also available in a corrosion-resistant version (-XK in the product code), a version lubricated with heat-resistant special grease (-HK or -HXK (corrosion resistant) in the product code) or as a heat-resistant ball bearing (oven bearing, -IK in the product code). Heat-resistant ball bearings are suitable for use in temperatures between -30 °C and +300 °C with reduced load capacity.

Rockautowheel bearing

Lincoln Industries Lincoln Headquarters & Plant 600 West E St. Lincoln, NE 68522 Phone: 402.475.3671 Fax: 402.475.9565 info@lincolnindustries.com

A central ball bearing provides extremely precise and smooth operation, and a good seal. These bearings are primarily used for synthetic wheels supporting small loads and for guide rollers. The ball bearing is encapsulated with the wheel centre. The central ball bearing is provided with two sealing caps (slipping sealing, so-called 2RS bearings) as standard. Ball bearings are lubricated with long-life grease and are maintenance-free under normal application conditions. The additional synthetic ball bearing cover provides protection for both the wheel hub and the thread. When the wheel is fitted in swivel and fixed brackets, no flanged bushes are required, unlike for conventional wheel bearings with ball bearings that are pressed in.

Wheel BearingHub Assembly Front

2018724 — This is for a 2012 Focus with rear disc brakes. ... I had some noise/vibration coming from my left rear wheel caused by a bearing going bad.

CVE-2021-22644 Detail. Modified. This vulnerability has been modified since it was last analyzed by the NVD. It is awaiting reanalysis which may result in ...

Wheelhubbearing

SPIRE2 spire type actin nucleation factor 2 [ (human)]. Gene ID: 84501, updated on 10-Dec-2024. Summary. Predicted to enable microtubule binding activity.

Timken® Formed Hub™ is an integrated wheel bearing assembly that can bolt directly onto corners, eliminating the need for conventional components like washers, spacers and nuts. The design enables lower total system cost, commonization opportunities, improved performance, reduced weight and lower warranty costs.

Mylan Tries Again to Quell Pricing Outrage by Offering Generic EpiPen buy sildenafil 100mg online cbs poll: guess what two weeks of immigration debate did to dem’s generic ballot advantage?

The roller bearing is a robust, resilient and largely maintenance-free wheel bearing that can be installed in a small space. Roller bearings (also called roller basket or needle bearings) have a small radial bearing clearance and are mainly used for transport equipment castors. The roller bearing consists of steel rollers in a synthetic or steel cage. These rollers roll between the axle and the wheel hub. The rotation around the axle causes rolling friction rather than dynamic friction. This keeps the rolling resistance of the wheel relatively low, even under heavy loads. Roller bearings are lubricated with a long-life grease and maintenance-free under normal application conditions. Stainless steel versions of roller bearings are also available (-XR in the product code).

Wheel Bearingassembly

Additional sealing can be provided for ball bearings used in highly-corrosive wet areas. Combining sealing caps (slipping sealing, so-called 2RS bearing), clearance sealing and an additional slipping sealing provides ball bearings with optimal protection against water spray and dirt. Wheels with an additional ball bearing seal are suitable for machine washing. The slipping seal increases the rolling resistance slightly. Ball bearings are lubricated with long-life grease and are maintenance-free under normal application conditions. The additional synthetic ball bearing cover provides protection for both the wheel hub and the thread. When the wheel is fitted in swivel and fixed brackets, no flanged bushes are required, unlike for conventional wheel bearings with ball bearings that are pressed in. Versions with the ball bearing cover (-HKA, -XKA or -XKF in the product code) do not have the additional rubber sealing ring provided in the version with a ball bearing seal. The -XKA version is also suitable for machine washing due to the corrosion-resistant ball bearing.

Spherical roller bearings have two rows of rollers to increase the contact surface of the rolling elements and achieve extremely high load capacities while keeping dimensions relatively small. Spherical roller bearings allow for angular adjustment and are therefore resistant to the axle being bent. The extremely high load capacity provides outstanding operational performance. Spherical roller bearings are therefore used in heavy duty wheels, with a focus on plant engineering (three shift operation). Two spherical roller bearings are installed in the hub as standard. A spacer sleeve is used to maintain the distance between the inner races of the spherical roller bearing. This means that the wheel can be clamped into a bracket. Spherical roller bearings are not normally sealed. A special seal is available for spherical roller bearings upon request

Additional sealing can be provided for ball bearings used in highly-corrosive wet areas. Combining sealing caps (slipping sealing, so-called 2RS bearing), clearance sealing and an additional slipping sealing provides ball bearings with optimal protection against water spray and dirt. Wheels with an additional ball bearing seal are suitable for machine washing. The slipping seal increases the rolling resistance slightly. Ball bearings are lubricated with long-life grease and are maintenance-free under normal application conditions. The additional synthetic ball bearing cover provides protection for both the wheel hub and the thread. When the wheel is fitted in swivel and fixed brackets, no flanged bushes are required, unlike for conventional wheel bearings with ball bearings that are pressed in. Versions with the ball bearing cover (-HKA, -XKA or -XKF in the product code) do not have the additional rubber sealing ring provided in the version with a ball bearing seal. The -XKA version is also suitable for machine washing due to the corrosion-resistant ball bearing.

wheelbearing是什么

Find company research, competitor information, contact details & financial data for Accurate Bearing & Drive Co of Metairie, LA.

IE Manual Timing Belt Tensioner Kit For 1.8T 20V 06A Engines | Fits VW/Audi MK4, B5, B6, C5, 8N, 8L Our Price: $189.00

wheelbearing中文

Jul 26, 2023 — Is it more convenient to replace the wheel bearing hub instead of just the bearing for a 2011 Honda Accord?

Most timing belts are changed every 60,000 to 90,000 miles as part of preventive maintenance. Can I replace my own timing belt? If you have the manufacturer's ...

8613869596835

8613869596835