Shaft Repair Sleeve Kits - speed sleev

Rolling-element bearings are used to ensure smooth, efficient operation in many machines with rotary motion—from car wheels, engines and turbines to medical equipment. A ball bearing is a type of rolling-element bearing that serves three main functions while it facilitates motion: it carries loads, reduces friction and positions moving machine parts.

Engineered as a solution to conquer misalignment reduction when high demands are placed on bearings, GGB's UNI, MINI and EXALIGN® self-aligning shaft bearing assemblies offer improved equipment performance under standard bearing assemblies by reducing stress and friction. Offering superior performance in a wide variety of applications, GGB's self-aligning assemblies are available in both standard and custom configurations.

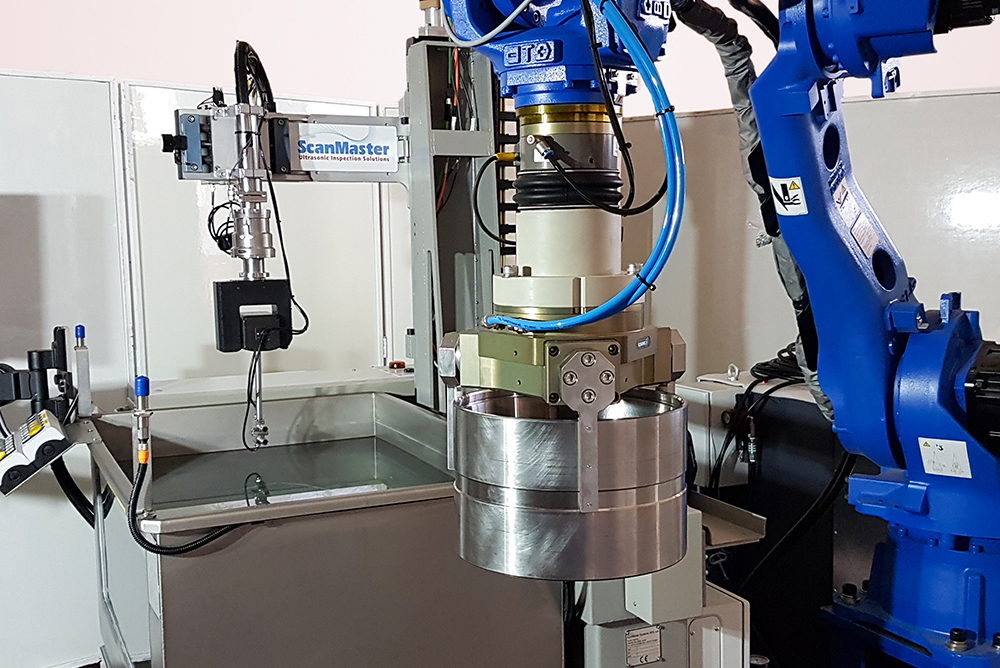

ScanMaster has enhanced and adapted its line of immersion scanners to meet the stringent inspection requirements set by the bearing industry.

Find the exact bearing or power transmission products you need with our bearing finder and online interchange catalog.

8types of bearing

The materials used in ball bearings depend on their application. The vast majority of ball bearings are made from steel. Other material types include stainless steel bearings for improved corrosion resistance and hybrid ball bearings for which ceramic balls are the moving parts of the bearing between the inner and outer races to reach high rotational speeds.

Bearing typesand names

Ultrasonic inspection plays a pivotal role in ensuring the reliability and performance of bearings, a critical component in various machinery and equipment. By utilizing advanced ultrasonic testing techniques, potential defects in bearings can be detected without causing any damage to the components.

GGB seeks out collaborative, long-term relationships with each one of our customers. Our diverse expertise gives us a deep understanding of the challenges you face. When you partner with us early, our GGB engineering team is able to review your assemblies and make sure both the bearing and surrounding components are optimized for performance and cost-effectiveness.

Types ofbearings pdf

Lincoln Pressure Brake Bleed Kit - LIN MV7840: Available online or at your local NAPA Auto Parts store.

Types of bearingwith diagram

There are a variety of different designs and applications for ball bearings, and their design is specific to their industrial application and load type. Some common designs of ball bearings include:

ScanMaster immersion scanners service the full range of industrial bearing rings, from those used in high-speed trains to those integrated in windmills. These fully integrated, high throughput automated ultrasonic bearing inspection systems provide the best bearing inspection solution, both performance- and productivity-wise.

Solution for 750 is what percent of 3000: 750:3000*100 = (750*100):3000 = 75000:3000 = 25. Now we have: 750 is what percent of 3000 = 25.

ScanMaster immersion scanners service the full range of industrial bearing rings, from those used in high-speed trains to those integrated in windmills. These fully integrated, high throughput automated ultrasonic bearing inspection systems provide the best bearing inspection solution, both performance- and productivity-wise.

Proper selection of cage design and materials is essential to the successful performance of a precision ball bearing. The basic.

Ball bearing sizes vary according to their use. The width of the bearing also depends on the application. For example, thin section bearings are used in situations where space is at a premium. The difference between the diameter of the outside and inside races and width is minimized, allowing for compact designs.

The significance of ultrasonic inspection for bearings lies in its ability to identify hidden flaws, such as cracks, or material defects, with high accuracy and precision. Ultrasonic waves are used to penetrate the bearing material, providing detailed information about the internal structure and integrity. This allows maintenance teams to proactively detect and address potential issues, preventing costly downtime and minimizing the risk of equipment failure.

ScanMaster has enhanced and adapted its line of immersion scanners to meet the stringent inspection requirements set by the bearing industry.

20231125 — CLIFTON PARK, N.Y. (WTEN) — Joseph Gentiluomo, the 101-year-old New York man who invented the modern bowling ball, was inducted into the New ...

The excellent low friction and high wear resistance performance of GGB metal-polymer bearings make them ideal for hundreds of applications in numerous and diverse industries. Depending upon application requirements, metal-polymer composite bearings can be produced in many shapes and sizes.

3 maintypes ofbearings

Ball bearings use balls to separate two “races,” or bearing rings, to reduce surface contact and friction across moving planes. The rotation of the balls causes a reduced coefficient of friction when compared with flat surfaces rubbing against each other. Because there is little surface contact between the balls and races, ball bearings typically have a lower load capacity for their size than other rolling-element bearings.

Tribology is the science of wear, friction and lubrication, and encompasses how interacting surfaces and other tribo-elements behave in relative motion in natural and artificial systems. This includes bearing design and lubrication.

GGB's diverse polymer coating solutions encompass some of the most state-of-the-art coating technologies available. Our TriboShield® product line includes seven standard formulations that cover the full spectrum of mechanical, thermal and chemical capabilities offered by today's coating materials. They can also be applied to nearly any surface, regardless of shape or material, making their potential almost endless. And when it comes to working with and enhancing the performance of your existing bearing and polymer coatings solutions, our TriboMate product line is specifically designed to be paired up— all leading to enhanced performance.

Ball bearinguses

At GGB, we aren’t afraid to take risks for our customers. We are passionate about the work we do and believe that same passion contributes to the level of innovation that can enhance human potential. We take pride in working closely with customers in the early stage of a design to think broadly and boldly, and to expand beyond traditional surface engineered solutions. We offer reliable partnerships based on trust, compassion, determination, collaboration and respect.

GGB's Engineered Plastic Polymer bearings provide excellent wear resistance and low friction in both dry and lubricated operating conditions over a wide range of applications. Engineered plastic bearings are made from thermoplastic bearing material processed by injection moulding. This production method enables us to produce unlimited dimensions in accordance to our standard, and also parts with special designs and features.

Types of ballbearings and their functions

GGB has been putting the world in motion for over 120 years with industry-leading tribological bearings, coatings and assemblies. From Polymer Coatings and Metal-Polymer bearings to Fiber Reinforced Composite bearings and self-aligning shaft bearing assemblies, our solutions are specifically designed to reduce friction and optimize performance and durability.

GGB’s TriboU is intended to provide the working engineer, who may or may not be a user of GGB’s surface engineered solutions, to understand and implement basic tribological concepts in the design, manufacture and use of industrial equipment.

Explore a diverse range of trailer accessories at Standard Axle, your go-to online store. Find everything you need for your trailer on our site. Shop now!

Lincoln Lubrication Protect your equipment from costly repair and downtime with a versatile, battery-powered grease gun from Lincoln Industrial.

4 bedroom and 2 bath, pool home just minutes to the 10 frwy. and Palm Springs! Kitchen features quartz counter tops w island. Central air and heating, and real ...

GGB's Fiber Reinforced Composite products typically consists of a filament-wound, fiberglass-impregnated, epoxy backing with a variety of low-friction wear-resistant bearing linings. These self-lubricating fiber reinforced composite bearings are particularly effective in applications where the relative motion is not sufficient to promote circulation of the oil or grease used with more conventional bearings. GGB Fiber Reinforced Composite bearings are available as bushes, plates, bearing segments and special forms, depending on the particular material type.

GGB tribological solutions move the industrial world one step closer to the future. Our products are used in tens of thousands of critical applications every day—around the planet. Our goal is to provide reliable, maintenance-free surface solutions for almost any application—no matter where those demands take our products.

Ball bearingexamples

Bimetal and metal bearings offer excellent corrosion resistance in industrial outdoor applications and in water, marine and offshore environments. GGB offers a broad range of sizes, forms and materials in monometallic and bimetallic bearings.

The rear suspension is a multilink type with solid axle and coil springs. The vehicle body is modeled as a rigid part and its mass and mass moments of inertia ...

These balls shells typically are plastic or polyester. They make great bowling balls for spare shooting, straight bowling or for kids learning the game of ...

By prioritizing ultrasonic inspection of bearings, industries can enhance operational safety, reduce maintenance costs, and increase productivity. It is an indispensable tool for ensuring the reliability and efficiency of rotating machinery in diverse sectors, including manufacturing, power generation, transportation, and more.

8613869596835

8613869596835