SKF 6218/C3 Deep Groove Ball Bearing - SLS e-shop - 6218

At Datwyler, innovation is a continuous journey. We’re constantly evolving our material technologies and developing sustainable solutions that lead the way in automotive sealing.

Datwyler’s global network of production facilities features the latest manufacturing equipment, producing elastomer parts that offer the highest levels of quality, durability, and consistency. Wherever you are, with a network of 11 sites across four continents and in-house mold shops, we offer our customers the benefit of local manufacturing facilities and support alongside full compliance with national regulations and cost-effective delivery.

Using decades of experience and the latest technology, Datwyler is constantly working on a range of new elastomer compounds for your application requirements. To meet the rapidly changing needs of the automotive sector, we have developed innovative materials that include among others flame-resistant materials, materials with electrical and thermal conductivity for effective insulation or sustainable materials.

In an industry where adaptation and advancement are key, Datwyler is at the forefront, bringing you the latest in smart materials, sensors, and actuators. Developed in collaboration with leading start-ups and technical schools, our innovative solutions are tailored to propel your operations into the future. Imagine harnessing the full potential of digitalization, IoT, energy harvesting, and intuitive human-machine interfaces – all integrated seamlessly into your workflow. Our expertise in solution design and material science translates into smarter, more efficient operations for your automotive business.

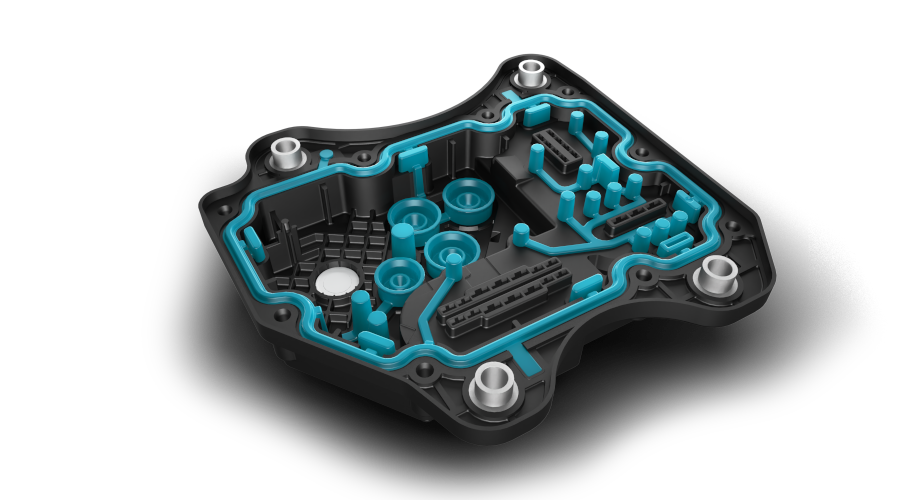

Our 2K parts seamlessly combine Liquid Silicone Rubber (LSR) and thermoplastics to create innovative, high-performance solutions for diverse applications.

Datwyler’s automotive customers benefit directly from our wealth of knowledge, cutting-edge technology, and ability to develop innovative materials and components. We deliver you solutions in surface treatments such as phosphating and cleaning, as well as the use of bonding agents and innovative material development. We have the ability to conduct high-level analysis of materials and multi-component products for improved quality and performance and to develop new innovations and solutions to drive the automotive market forward, and to ensure the future is both sustainable and successful.

Our ideal customer project is one that is built on collaboration. The combination of ideas, inspiration, and knowledge from our experts and yours provides a solution that fulfils all your requirements using the latest materials, simulation technologies, and production processes. Our co-engineering service offers 360-degree support, taking you through all stages of development. From initial assessment, idea generation, and early prototypes to simulation, testing, and molding, we offer the complete package for the most complex components, using our world-class state-of-the-art equipment and materials expertise to turn your designs into reality.

As the world shifts towards cleaner, more sustainable energy solutions, your business needs to stay ahead of the curve. Datwyler is your ally in this transition, with our groundbreaking work in hydrogen technology, energy storage, and battery solutions. We’re committed to equipping your business with the tools and technologies needed to lead in this era of electrification and sustainability. With Datwyler, stepping into the future of energy is not just a vision; it’s a reality.

O-Rings may be small in size, but their importance is huge. They are a key component in almost every area of conventional, hybrid, and electric vehicles, with their precision, durability, and highly customizable properties making them core elements of a wide range of systems. From conventional applications such as braking, fuel management, transmission, and steering to new applications such as battery cooling and fuel cell technology, the small but mighty O-ring is critical.

Our innovative approach is about more than just meeting current needs – it’s about setting new standards and exploring how these advancements can benefit your operations and the broader industry.

We provide LSR components tailored to meet the specific needs of the automotive sector, ensuring high performance and reliability.

Our HCR products are designed for exceptional heat resistance and durability, making them perfect for demanding applications in various industries.

At Datwyler, we understand the unique challenges and demands of the Automotiveindustry. Our core competencies are not just the backbone of our operations; they are the driving forcebehind the tailored solutions we provide to you.

Message: Visual Text Hi,

I wanted to share this interesting link with you: https://datwylersealing.com/industries/automotive-sealing/. I think you'll find it interesting.

Feel free to check it out when you have some time. Let me know what you think!

Best regards,

8613869596835

8613869596835