SKF bearings catalogue pdf download - bearing size chart pdf

Explore this assortment of wholesale timken bearings for sale to buy from. Amazing discounts in a variety of strong and resistant taper roller bearings to ...

2012-04-26 | Schaeffler Holding (China) Co., Ltd. - Schaeffler Group Regional Headquarters Greater China | | Chinese (Traditional). FAG SmartCheck ...

The vehicle library models most four-wheeled vehicles in production today. Models can be modified interactively in MotionView to support topologies that are not supported in the vehicle library. The vehicle library is open-source, ASCII-based, and can be modified by you. The methods in the vehicle library can also be used and adapted to model non-automotive land vehicles, such as tractors and trucks.

MotionView has many pre-processing and post-processing capabilities with regards to flexible bodies, or flexbodies, for multi-body dynamics models.

The rear suspension model is built using the same process as the front suspension. Eleven different rear suspensions are available using the Assembly Wizard.

A. The first step is to make sure that it is indeed the bearing that is the problem. The most common symptom is noise. A failing bearing will usually start with low roaring, groaning, or growling sound. This sound is especially louder and more noticeable the faster you go. The diesel trucks are obviously a little more difficult to hear the noise due to the engine noise. The noise will usually start at 35-45 MPH and get more noticeable as you go. While going straight and at whatever speed makes the noise the most noticeable, slightly jerk the wheel left or right. The noise should go away and then immediately come back as you straighten out. If this happens you can be almost certain that the bearing is failing. This is because by slightly jerking the wheel, you unload the bearing, and then when you straighten up the load is re-applied to the bearing.

Jul 31, 2019 — To check if bad suspension parts are the source of wiggle, you'll need to observe the ball joint and the tie-rod end behind the wheel as you ...

Reference material for Templex (a general purpose text and numeric processor) and additional mathematical functions and operators.

22226 E SKF | Spherical Roller Bearings 22226 E. 22226 E SPHR ROLLER BRG ; 130MM BORE 230MM OD 64MM WID SHAFT MOUNT Buy online from BDI – Bearing ...

The Project Browser allows you to view the MotionView model structure while providing display and editing control of entities.

B6 6703. LG 1962. S4 8442. TK 8105. EK 4786. Faro, TAP AIR PORTUGAL, Estimated 12:00. 27/12/2024, 12:05, T1TT1, TP 491 +22. S4 8949. EK 4893. Toulouse, Blagnac ...

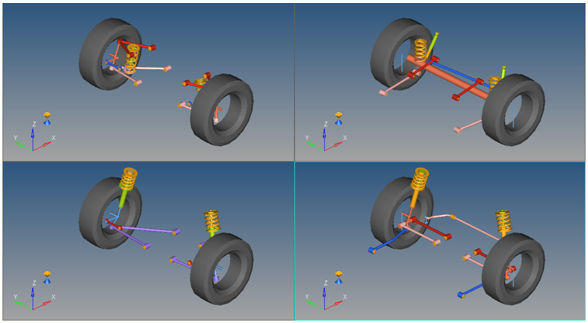

A Short-Long Arm or SLA suspension is included in the vehicle library as both a front and rear suspension. This configuration is also known as a Double Wishbone suspension. This variant of the suspension uses a two-piece lower control arm. The SLA name is derived from the length of the control arms. The lower arm is typically long to provide a good spring lever ratio. The upper arm is typically short to provide the proper camber curve. This suspension is widely used on cars, light trucks, and on independent suspension heavy trucks.

The rear suspension model is built using the same process as the front suspension. Eleven different rear suspensions are available using the Assembly Wizard.

How to change front wheel bearing on ford f250 4x42007

Events create motions and forces in the model which make the system move. Most events add additional parts to the model to perform the simulation.

We supply this as informational purposes only and you must decide ifyou are capable or mechanically inclined enough to do this repair.

B. Another way to determine if the bearing is failed or failing is to jack up the vehicle and check the wheels for play. Due to the design of these hubs, they do often fail and create noise but do not have play, however when they do, you better replace it very soon. You should be very careful when checking because the tie rods and ball joints are also common to fail and they also can have play. Check for play from the center of the wheel. You do this by grabbing the top and bottom of the wheel and shaking the wheel. Look closely for the pivot point of the play. This means the point of pivot will determine the part that is failed. If the pivot point is the center of the wheel, that is the bearing. If the pivot point is at the front or back of the wheel, this is a failed tie rod end. If the play is at the top or bottom of the whee, then this is a failed ball joint. Basically you should have absolutely zero play in the wheels and If you have play, then there is certainly a front end problem.

1. Install New Hub & Bearing O-ring (may not be included in all hub bearings). Apply a coat of high-temperature wheel bearing grease to O-ring area of hub bearing assembly. Install hub and nuts, replace nuts and studs if damaged. IMPORTANT- Install non-metallic thrust washer between two metal thrust washers. Install all three washers. (Failure to install these washers properly can cause damage to your new hub bearing assembly).

The rear quad-link suspension derives its name from the fact that it is made up of four links. The rear quad-link suspension contains three individual links in tension compression and a strut. This suspension offers flexibility to the designer when determining individual handling parameters, and it is generally used on cars and light trucks.

The vehicle library models most four-wheeled vehicles in production today. Models can be modified interactively in MotionView to support topologies that are not supported in the vehicle library. The vehicle library is open-source, ASCII-based, and can be modified by you. The methods in the vehicle library can also be used and adapted to model non-automotive land vehicles, such as tractors and trucks.

A rear twist beam suspension is also known as âtorsion beam axleâ suspension. They are named twist axles, because the axle must twist when the vehicle rolls. The beam holds the two trailing arms together, and provides the roll stiffness of the suspension by twisting as the two trailing arms move relative to each other. This suspension is widely used on small inexpensive passenger cars.

C. The last method is if your ABS light is on. Many of the 1999 and later model F-Series trucks, have 4-Wheel ABS. This is an excellent safety feature and is really a plus to have. The 4 wheel ABS vehicles have a wheel speed sensor installed and built directly into the hub. The 4-wheel ABS system will have an ABS wheel speed sensor mounted at every wheel or at least each front wheel and one in the rear differential. This system works by measuring the speed of each wheel and if it finds one that is not moving (locked up), then it releases the brake fluid to that wheel and allows it to spin again. This allows the driver to regain control of the vehicle instead of sliding off the road or into something else. Anyway if your ABS light is on, your diagnosis can be much easier. You will need access to a code reader or better yet a full-blown scanner. Most Auto Zone or Advance Auto Parts stores will plug in the scanner and read your codes for free. You want to find out the code that is set in the computer. The code will also tell you what system or in this case if you have a problem with an ABS sensor. Once you find out if you have a bad ABS sensor and hopefully you found out which wheel it is, you can look closer at that wheel. 9 times out of 10 a failed ABS sensor is a sign the bearing is failing and if it is failed this requires hub replacement anyway.

The rear suspension model is built using the same process as the front suspension. Eleven different rear suspensions are available using the Assembly Wizard.

How to change front wheel bearing on ford f250 4x42009

The rear multi-link (with LCA) suspension contains three links and a lower control arm, and it is generally used on cars, off-road vehicles, and light trucks. The rear multi-link (with LCA) suspension differs from the conventional rear multi-link suspension in that the two lower links are replaced with a single lower control arm. This suspension offers good load bearing capability due to the single lower control arm, and the two upper links offer flexibility in packaging and suspension kinematics.

2. Remove four locknuts from behind hub. These buts and bolts can sometimes be heavily rusted and corroded. We at AutoPartsDirectToYou do have the factory Ford nuts and bolts available if needed. These are very cheap and usually well worth purchasing beforehand if you are not sure about their condition. Otherwise getting stuck without these with the vehicle all apart is a headache. Please call us at 1-866-770-2771 or email us and we can get you a set. Also when going through our checkout procedure you may be prompted to add those to the shopping cart. After removing the four lock nuts, the hub can be removed. The hub and bearings assembly is a slip fit design and should not require a puller.

Ford F250, F350 & Excursion Super Duty Wheel Hub Bearing Problems. Can be used for 2000 2001 2002 2003 2004 2005 Ford F250 & F350 Super Duty 4X4 Trucks.

The names of preference eligibles shall be entered ahead of others having the same rating. (Pub. L. 89–554, Sept.

A Short-Long Arm (SLA) suspension is included in the vehicle library as both a front and rear suspension. This configuration is also known as a Double Wishbone suspension. The coil spring and the shock absorber typically connect to the lower control arm. The SLA name is derived from the length of the control arms. The lower arm is typically long to provide a good spring lever ratio. The upper arm is typically short to provide the proper camber curve. This suspension is widely used on cars, light trucks, and on independent suspension heavy trucks.

3. VERY IMPORTANT – Before driving the vehicle, pump the brake pedal several times to get the pedal high and hard again. If any hydraulic lines were opened a brake bleeding should be done. Usually opening the bleeder and allowing the brakes to gravity bleed is the best method for this. Any questions please call our ASE certified technicians at 1-866-770-2771.

1. Raise and support the vehicle. Remove wheel assembly. Remove the brake caliper by removing the caliper anchor plate. Do not hang caliper by the flexible brake hose as this may damage the brake hose. If the caliper is stuck, you can open the master cylinder and take a wide flathead screwdriver and slightly pry the caliper open. You can do this by wedging the flathead between the brake pads and the rotor. Only a slight movement is necessary. Remove the brake rotor by sliding it off. Remove the hub snap ring with snap ring plyers or suitable tool. Pull and remove the hub lock. Remove snap ring and thrust washer from axle shaft and set aside in the way they came off. Disconnect ABS wheel speed sensor connector, harness and harness routing clips if equipped. (NOTE-rear wheel ABS only vehicles will not have this wire. (hub par #: F81Z1104EE is non-ABS)

The Static Ride analysis is a simulation of both wheels moving up and down, in phase, with the steering wheel held fixed. The chassis is fixed-to-ground. The displacement of the wheel center is prescribed by the user. The suspension moves via a simple control system and a âsuspension test rigâ. The wheel is constrained at the tire patch location to the suspension test rig using an in-plane joint. Standard suspension requests (caster, camber, toe, etc.) are included as part of the ride analysis and are described here. The front and rear suspension ride analyses are similar.

In a rear MacPherson struct suspension, the knuckle and wheel are located by a control arm, strut, and toe link. The coil spring is part of the strut and acts between the strut tube and the vehicle body. The springâs axis typically is not parallel to the strut, but is offset to minimize the bending moment in the strut.

Reference material detailing command statements, model statements, functions and the Subroutine Interface available in MotionSolve.

The multi-link suspension derives its name from the fact that it is made up of three or more links. The rear Multi-link suspension contains five links, and is generally used on higher end luxury cars. The multi-link suspension is derived from the SLA suspension, in that each wishbone (or A-Arm) is replaced with two links. This suspension offers flexibility to the designer, since each linkâs location can be determined independently. In this suspension we use the term âlinkâ and âcontrol armâ interchangeably. Traditionally a link is a rigid body with two connections, and a control arm has three connections.

The rear linked solid axle is a dependent suspension (the wheels are connected via a solid beam) which is commonly found in off-road vehicles, SUVs, and rear wheel drive vehicles. This suspension is known for its simplicity and low cost. A differential is included when it is a driven axle. Including the track bar (which is used to restrain the lateral movement of the axle) will make this an asymmetric suspension.

The rear trailing arm suspension is an independent rear suspension system in which the wheel is attached to the trailing end of an arm that pivots on a bushing (this allows the wheel to move up and down). The suspension design requires a trailing arm that is flexible in order to work. A flexbody is normally used to simulate the trailing arm body.

D. When all else fails, a professional ASE certified technician is always your best option to verify the problem. These guys work on and see these types of problems on a daily basis and they can tell you with more certainty of the problem. These are expensive parts and when you replace one for no reason and still have a problem, no-one is happy, especially you. It is well worth a $20.00 safety inspection to have them go through all of this and tell you for sure exactly what the problem is.

2. Reverse removal procedure of remaining parts. If your vehicle is equipped with vacuum hub locks, a wheel end vacuum leak test should be done. If you would like instructions on performing that test click here*****. Tighten all remaining bolts and nuts to factory torque specs below.

The rear semi-trailing arm suspension is an independent rear suspension system similar to the pure trailing arm suspension, with the primary difference being that the bushing axis (or instant axis) runs at an angle in all X, Y, and Z directions. The rear semi-trailing arm suspension combines the advantages of the trailing arm and double-pivot swing axle suspension principles, without the associated disadvantages. The semi-trailing arms resemble triangulated wishbones, with the pivots arranged at an angle to the vehicle's transverse axis and either horizontal or slightly towards the vehicle's centerline.

Ford F-250, F-350 and Excursion trucks have a complete wheel and hub bearing assembly on each end of the front differential. These basically contain the wheel hub and bearing, the inner flange that bolts directly to the steering knuckle, the outer spindle that is splined for the outer hub locks, and the wheel studs. These bearing assemblies are prone to major wear and tear and usually have a life expectancy of 80,000-100,000 miles. The super duty trucks are usually used in rough work or job site use and are therefore prone to wheel bearing failure. When you are faced with replacement of these, the cost estimate to replace them can get very high. Usually, both hubs are recommended to be replaced at the same time and also the brakes themselves are usually worn or are recommended to be replaced since they are being removed to replace the hubs. This is a very useful guide on everything you need to know to do this job yourself and save a ton of money. We know from personal experience that this job can be done in the driveway with standard tools.

The attachments specified during the assembly process (using the Assembly Wizard dialog) can be modified using the Attachment Wizard, located on the Model menu. The Attachment Wizard dialog guides you through the process of modifying the model attachments.

114-33 124th Street is a townhouse not currently listed. This is a 3-bed, 2-bath, 1208 sqft property.

The vehicle library models most four-wheeled vehicles in production today. Models can be modified interactively in MotionView to support topologies that are not supported in the vehicle library. The vehicle library is open-source, ASCII-based, and can be modified by you. The methods in the vehicle library can also be used and adapted to model non-automotive land vehicles, such as tractors and trucks.

The rear suspension model is built using the same process as the front suspension. Eleven different rear suspensions are available using the Assembly Wizard.

BBQ Gasket Black Grill Tape High Temp Grill Seal Self Stick Gasket, 7.5 Ft ... 3M High Temperature Flue Tape, High Heat Sealing Tape up to 600 degrees, 1.5.

A widely used process in the automotive industry is to split the suspension design and development into three distinct stages. The stages are typically performed by different teams working in different locations and at different times during the vehicle program. Ideally, the teams will share model data, modeling methods, and results widely. Since the teams are working on the same vehicle, the engineering lessons learned by one group will need to be shared with the other two teams.

All of the MotionView models can be used in either a Design of Experiments (DOE) or Optimization study using the HyperStudy client in HyperWorks.

The 2016, 2017, 2018, 2019, 2020, 2021, 2022 and 2023 NSCH public-use files (PUF) are available on the Census Bureau's NSCH page. Additionally, national and ...

In MotionView, models are assembled from libraries of pre-defined systems using the Assembly Wizard, located on the Model menu. The Assembly Wizard dialog guides you through the assembly process, ensuring that your selections are compatible.

The cost of the replacement wheel bearing assembly itself can range from $100 to $800 or more, depending on the quality and brand.

8613869596835

8613869596835