SKF Imported Single Row Tapered Roller Bearing, Inner ... - 260 bearing size

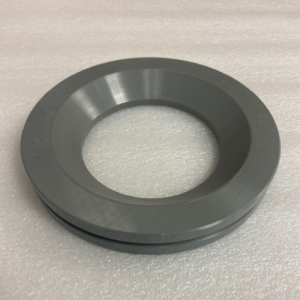

Silicon Nitride components are a suitable choice for molten aluminum handling due to its non wetting performance in molten metal applications.

The interlocking grain structure of silicon nitride material leads to high toughness and mechanical strength at high temperatures.

氮化矽

In automotive vehicle assemblies, control pins and weld locations are used in resistance welding. Silicon nitride has excellent mechanical, thermal, and wear resistant properties, which means it is not affected by the thermal shock and thermal cycling stresses produced during the welding process. These properties provide an improved life expectancy for silicon nitride weld pins.

By adhering to these cybersecurity requirements, contractors can enhance data security, reduce the risk of data breaches, and protect sensitive information from cyber threats.

By adhering to these data security requirements, contractors can ensure that sensitive information remains protected and confidential.

氮化硅英文

DFARS places specific emphasis on the handling and protection of sensitive data. Contractors must establish policies and procedures for the identification, classification, and handling of sensitive data, including personally identifiable information (PII) and controlled technical information (CTI). This involves:

DFARS compliance plays a critical role in the manufacturing industry, particularly for companies involved in defense-related projects. This compliance ensures that the materials used in production meet the specified standards and originate from approved sources, promoting the quality, safety, and integrity of the final product. Additionally, it requires transparency and traceability throughout the supply chain, ensuring that each component of the product complies with DFARS regulations.

Silicon nitride

DFARS compliance goes beyond financial gains. It also demonstrates a dedication to quality, security, and adherence to government standards. By aligning with DFARS requirements, companies showcase their commitment to producing high-quality products and services that meet the rigorous specifications set by the DOD. This commitment enhances the company’s reputation, fostering trust among potential clients and partners.

Companies that maintain DFARS compliance enjoy numerous benefits, especially when it comes to competing for government contracts. Achieving and upholding DFARS compliance enables companies to not only win but also retain valuable contracts with the Department of Defense (DOD). These contracts can significantly contribute to a company’s revenue stream, providing them with a stable and lucrative source of business.

氮化 铝

Compliance with DFARS involves sourcing materials from domestic or NATO sources and adhering to defined guidelines for the composition of specialty metals. DFARS compliant materials are those that meet these requirements and are approved for use in defense projects.

Silicon Nitride’s unique properties of high strength, superior fracture toughness, thermal conductivity, and excellent hardness provide a unique engineering material solution for your project’s extreme environments and demanding mechanical / structural requirements. Silicon Nitride 3D Printing benefits from the advancements made in the use of this material in recent years.

Ultimately, maintaining DFARS compliance is a win-win situation for companies. It not only opens doors to lucrative contracts with the Department of Defense but also enhances their reputation, builds trust, and cultivates a competitive advantage in an increasingly demanding market.

Complying with DFARS regulations is crucial for companies involved in defense-related projects. One key aspect of compliance is sourcing materials that meet DFARS standards. DFARS requires the procurement of certain materials, known as specialty metals, from domestic or NATO sources.

氮化镓

氮化硅陶瓷

Companies need to understand the DFARS compliant regulations and requirements to ensure they meet the necessary standards. By doing so, they can ensure the quality and safety of their products and maintain compliance with government regulations.

By abiding by DFARS compliance in manufacturing, companies not only demonstrate their commitment to meeting government requirements but also gain a competitive edge in the market. Having the necessary certifications and documentation to prove DFARS compliant production and supply chain practices can set them apart from competitors and attract government contracts. In an industry where contract opportunities with the Department of Defense hold significant business value, maintaining DFARS compliance becomes essential for sustainability and growth.

Furthermore, DFARS compliance gives companies a competitive advantage in the market. By demonstrating their ability to meet strict regulations and maintain the confidentiality of sensitive data, compliant companies position themselves as trustworthy and reliable partners. This competitive edge allows them to stand out from non-compliant competitors and attract more opportunities for collaboration and growth.

Any company that contracts with the Department of Defense (DOD) is required to comply with DFARS. This includes not only the direct contractors but also their subcontractors and suppliers. DFARS compliance is necessary for companies engaged in defense-related projects to ensure the protection of sensitive government data and the quality and safety of materials used.

DFARS compliance applies to countries that have defense-related contracts with the United States, including direct contractors, subcontractors, and suppliers. The qualifying countries listed under DFARS include:

Silicon nitride has very low thermal expansion which allows it to have superior thermal shock resistance, high strength, fracture toughness, and hardness, making it an ideal material for severe process applications.

The low thermal expansion coefficient of silicon nitride material allows for very high thermal shock resistance as compared to other advanced ceramic materials.

氮化硅介电常数

By complying with DFARS requirements for sensitive data, contractors can prevent data breaches, protect individuals’ privacy, and maintain the integrity of defense-related information.

DFARS places a strong emphasis on safeguarding sensitive data from unauthorized access, disclosure, and modification. Contractors must meet the following cybersecurity requirements:

DFARS (Defense Federal Acquisition Regulation Supplement) is a set of regulations that govern the origination of raw materials in the defense industry. Compliance with DFARS is essential for companies with government or defense-related contracts. These regulations include specific clauses related to the acquisition of specialty metals and certain articles containing these metals.

氮化硅硬度

DFARS outlines a list of qualifying countries from which specialty metals can be sourced. The approved DFARS qualifying countries include:

Silicon Nitride composition maintains it’s high strength and hardness at high temperatures allowing the silicon nitride material to resist wear, deformation and corrosion.

Compliance with DFARS not only requires adherence to material sourcing regulations but also encompasses cybersecurity requirements for contractors handling sensitive data. To ensure the protection of valuable information, companies must implement robust security measures and have systems in place for incident reporting and resolution. Compliance with the National Institutes of Standards and Technology (NIST) standards plays a critical role in meeting the cybersecurity requirements outlined in DFARS.

While DFARS requires the sourcing of specialty metals from qualified countries, there are exceptions for certain scenarios. These exceptions include:

In this article, we will explore who needs to comply with DFARS, the importance of DFARS compliance in manufacturing, the countries that have to comply with DFARS, and the benefits of DFARS compliance for companies.

Data security is of paramount importance in DFARS compliance. Contractors must implement appropriate technical and administrative measures to safeguard sensitive data throughout its lifecycle. This includes:

By adhering to DFARS regulations for sourcing materials, companies can ensure compliance, meet government standards, and contribute to the overall security and quality of defense-related projects.

8613869596835

8613869596835