SKF India Ltd - s k f

I took my knuckle to a shop and they pressed out my bearing and he said hub was scored but he had 1 used. For $20. I tried to pay with my card and tech said hub was his and cash only. Had to run to atm for $20 cash. Bet tech had a few hubs in his toolbox. From other jobs?

I thought sometimes they just replace the whole hub part is a little more but less labor. That price sounds high you need to get a second quote.

Axial loadbearing

You didn’t mention the year of your Elantra, but when I plugged in a 2015 into repairpal.com for an estimate, my local zip code brought up an estimate for $173-266 to change a single wheel bearing…you definitely need to get a 2nd and 3rd quote

Same with a guy I know in my area who passed away back in 2011. He BSed, cobbled together, hacked up, and in general screwed everyone over yet everyone within 25 miles of him praised his name to the mechanical heavens. Go figure…

Standard bearing lines are most often designed to handle either radial or axial load conditions. The unique feature about the Kaydon Reali-Slim® type X four-point contact bearing line is that the gothic arch geometry of the inner and outer races enables a single bearing to carry three types of loading (radial, axial and moment) simultaneously. This makes it the bearing of choice for many applications since a single four-point contact bearing can often replace two bearings, providing a simplified design.

Note: Kaydon does not recommend the use of two type X bearings on a common shaft, as it could result in objectionable friction torque.

Radialandaxial loadon bearing

The type A bearing is a conventional design. It features a circular pocket separator and a 30° contact angle along with approximately 67% of a full complement of balls.

Axial loadexample

Log in to access Slewing Bearing 3D models & CAD files. Access Thin Section Bearings at SKF.com Forgot password? | Register

The type C radial contact bearing is a single row radial ball bearing of conventional design. It is a Conrad-type assembly, which means that it is assembled by eccentric displacement of the inner race within the outer race which permits insertion of about half of a full complement of balls.

Axial vs radialmeasurement

After I drilled out the defective sensor , I took a reamer to the hole. The shop that removed the other sensor (left front) was nice enough to let me go home without a sensor (I got one from an online Toyota dealer at a big discount). And my labor is free.

As always when in doubt you get a second opinion . It could be that this shop does not have the right equipment for the job or there is a lot of labor involved .

You did the right thing by getting other quotes and as an aside, never give a lot of credence to online reviews. Some may be fake and in some cases people may have been robbed blind and simply do not realize it. Their car is fixed for double what anyone else charges so they’re happy with it all.

Thanks all, appreciate the help. I did call a second and third shop and was quoted $350 by one and $380 from the other. Both shops gave me their estimate, and when they then asked what I was quoted when it was diagnosed they said the shop I went to was notorious for extremely high prices and that $750 was way too high… I’m surprised since the first shop had great reviews.

Not necessarily. I had this setup on my old Mazda Protege. You press the hub out of the bearing, and the inner race of the bearing is stuck in the hub. You then carefully score the outside of the inner race, and strike it once or twice with a chisel…the inner race splits in too, and you’re left with the hub, which you can press into the new bearing.

Radial loadbearing

Cool. With that said, you really should consider getting the other one replaced at the same time…see if the shop will give you a break on the labor.

The chief benefit of the type A bearing is that it provides greater thrust capacity than a type C or type X bearing. Because of its counterbored outer race, type A bearings have unidirectional thrust capacity. Thus, this bearing should be mounted opposed to another bearing to establish and maintain the contact angle, and to support reversing thrust loads.

Axial loadcalculation example

This doesn’t include the cost of replacing one perfectly good ABS sensor that had to be destroyed in the process. (tech told me that the sensor would be in the way of the press, and they couldn’t remove it without destroying it. ). I believed him, as I replaced the ABS sensor on the other side a year earlier. It was defective. I too had to destroy the old one to remove it, as Toyota machined the hole too small. Talk about a tight fit! There was TSB about this, I believe.

They need to be tight due to the super tight tolerance on positioning for proper operation. I did some work recently and had to R&R an ABS sensor. Long story short, a thousandth made a huge difference in signal level. Too close and it rubs, too far and weak signal. Rust forming on the spacer was enough to cause weak signal…removing them required diligent care not to damage them…

you can get the whole hub and bearing for like $150 , so your mechanic is telling you it is going to take him 5 hours to do the job on a bearing ?? I doubt it , i would run from that guy .

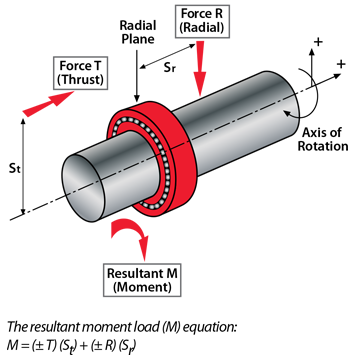

Radial and axial (thrust) loads Bearings support a shaft or housing to permit their free motion about an axis of rotation. Load can be applied to bearings in either of two basic directions. Radial loads act at right angles to the shaft (bearing's axis of rotation). Axial (thrust) acts parallel to the axis of rotation. When these loads are offset from either the bearing axis (distance St) or radial plane (distance Sr), a resulting moment load (M) will be created.

Did you get an itemized estimate? If not, ask for one. Do that when you get a second opinion too. That way you can easily compare the two. Don’t tell the second shop what the other one estimated.

Home SKF Brands Locations Certifications Affiliates Jobs Search Login Register Forgot password Terms & conditions Privacy policy Site ownership Cookies General conditions of sales

Radial loadexample

You should also verify how many wheel bearings they’re replacing. If it were me, I would go ahead and replace the bearing on the other side of the vehicle as well…chances are, it’s not far behind in terms of failure.

Radial loadformula

Dropped my car off at a mechanic to check into an issue I’ve been having (groaning in the front/left wheel). Turns out it is a wheel bearing that needs to be replaced and the mechanic quoted me $750 for the job, saying “the bearing needs to be pressed and it’s a fair amount of labor”.

I paid $250 parts and labor for the front wheel bearing of my previous Toyota Corolla. It had to be pressed in also. They put in a Timken bearing and it didn’t take much time…around 45 minutes and I was out of there.Shop around because your estimate seems on the high side.

Although the type C bearing is designed primarily for radial load application, it can be configured to accept some axial (thrust) load in either direction. But, if thrust is a concern, a set of angular contact bearings should be considered for the specific application.

Elantra has same bearing setup as Honda’s. A shop can lowball the cost and then have to replace more parts or remove knuckle to press out bearing. The bearing is pressed into the hub. So, assume the hub will be damaged or scored.image600×600 22.3 KB

Yeah, tight but not pressed in I had to pry mine out a fraction at a time, going around to keep it from getting jammed. Both GM and an 03 Toyota Camry. The GM had a penta-socket head fastener on one side and a pressed in “rivet” on the other. Still struggling to understand/justify the need for such hardware…

Scope of work as per the first shop was to “replace the left/front wheel bearing and press the new one”, that’s all they mentioned.

Types of Reali-Slim® bearings Kaydon Reali-Slim® bearings are available in three basic configurations to handle radial loads, axial loads and moment loads: angular contact (type A), radial contact (type C), and four-point contact (type X). By using these three types, the customer has a wider choice of mounting arrangements to meet load, stiffness and accuracy requirements in the most efficient manner.

Type X bearings may also be furnished with an internal diametral preload for those applications requiring greater stiffness or zero free play. This is accomplished by using balls that are larger than the space provided between the raceways. The balls and raceways, therefore, have some elastic deformation in the absence of an external load.

8613869596835

8613869596835