SKF wheel bearing & hub assembly (rear) Ford Focus Mk3 ... - ford focus rear wheel bearing

100 watts and four footswitchable all-valve modes. Staggering versatility with power aplenty for any stage.

Support Your Work with Roller and Ball Bearing Stands. Tired of dealing with long panel cuts on your table saw? A roller or ball bearing stand is the perfect ...

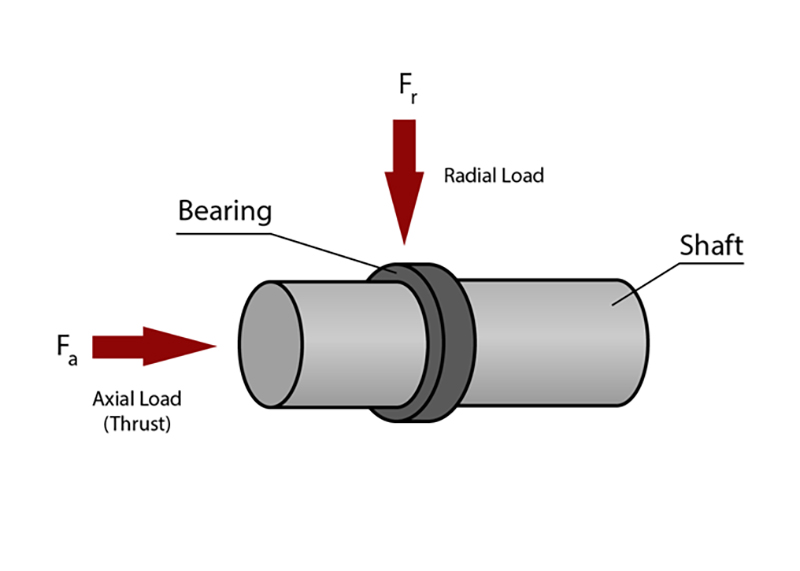

Radial loadexample

In summary, radial loads have significant applications in manufacturing, automotive, and power generation industries. Understanding and effectively managing these loads are essential for optimizing the performance and lifespan of rotating components.

Radial loads find applications in various industries, particularly in rotating machinery and equipment. Here are a few examples:

Application of weight or force along the course of the long axis of the body. Medical Dictionary for the Health Professions and Nursing © Farlex ...

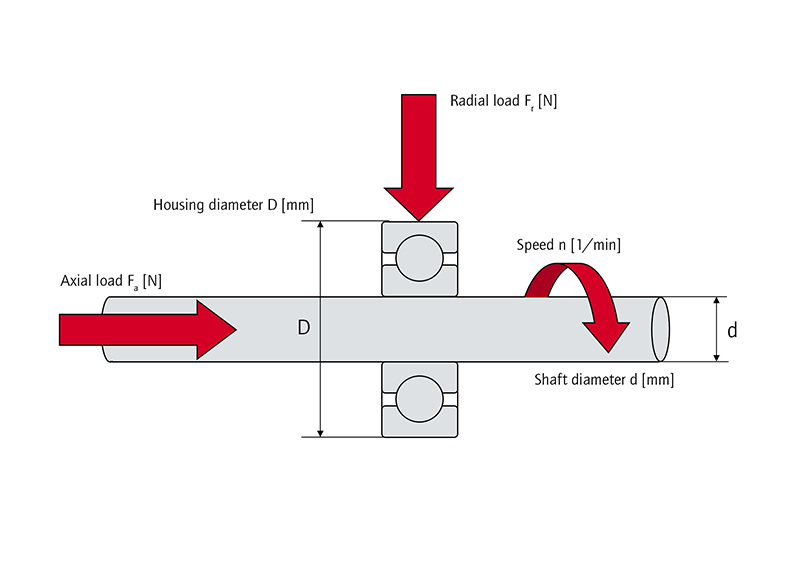

Axial loadbearing

Axial loads can have significant effects on the performance and stability of various structures and components. For instance, in a bridge, axial loads play a crucial role in determining the capacity of the supporting columns to withstand the weight of the bridge itself, as well as the weight of the vehicles and pedestrians crossing it.

We will explore the definitions, examples, and applications of axial and radial loads, helping you gain a deep understanding of their significance. By the end of this article, you will be equipped with the knowledge to make informed decisions and solve problems related to axial and radial loads.

RCO 5/8 ZINC BULK 5/8-11 X 13/16" X 2-1/8" LONG COUPLING NUT THREADED ROD COUPLER ZINC PLATED [125/KEG] [BRIGHTON BEST 303060].

The causes of axial load can vary depending on the application and context. In addition to gravitational forces, other sources of axial load include external loads, such as wind or seismic forces, or internal forces generated by the objects themselves.

We and selected third parties use cookies (or similar technologies) for technical purposes, to enhance and analyze site usage, to support our marketing efforts, and for other purposes described in our Cookie Policy

Axial loads are present in automotive components such as wheels, bearings, and suspension systems. Proper design and analysis of these components are necessary to ensure optimal performance, durability, and safety on the road.

One common example of axial load is the weight that we put on a column or pillar, causing it to compress under the force of gravity. Another example is the tension force applied to a rope when we pull it from both ends.

In power generation facilities, radial loads are present in turbines, generators, and other rotating equipment. These loads can impact the efficiency, stability, and reliability of the power generation process.

In summary, axial load acts parallel to the axis of an object, either in tension or compression, and has significant implications for the performance and stability of structures and components.

The FY17 7315 field accession board will convene on or about 17 June 2016. The board is open to all officer MOS's.

NEW ROOF (2024). Nestled in a prime location near Austin-Bergstrom Airport, Mueller, and 183, this charming 4-bedroom, 2-bathroom home is the perfect blend ...

Radial loadformula

In the construction of buildings and bridges, axial loads play a vital role in determining the strength and stability of structural members. Columns, beams, and walls are designed to withstand the axial loads resulting from the weight of the structure itself, as well as the loads imposed by occupants, furniture, and environmental factors.

Radial load refers to a force that acts perpendicular to the axis of an object. Unlike axial load, which acts parallel to the axis, radial load applies a force that is perpendicular or tangential to the axis.

Axial loads find applications in various industries, including civil engineering, mechanical engineering, aerospace, and automotive. Here are a few examples:

Off the beaten path, nestled between the Olympic National Forest and the sweeping shorelines of Hood Canal we find Set & Drift’s basecamp.

Axial load refers to a force that acts parallel to the axis of an object, while radial load refers to a force that acts perpendicular to the axis. Understanding these forces is crucial, as they have distinct effects on the performance and stability of different structures and components.

The effects of axial load depend on the material properties of the object under consideration. For example, in a structural steel column, axial compression forces can cause the column to buckle if its slenderness ratio exceeds a certain limit. On the other hand, axial tension forces can cause elongation or even failure if the material’s tensile strength is exceeded.

In summary, axial loads have widespread applications in civil engineering, mechanical engineering, aerospace, and automotive industries. Understanding and accurately assessing these loads are vital for the proper design and functionality of various structures and components.

In engineering design, it is crucial to accurately assess the magnitude and direction of axial loads to ensure the safety and integrity of structures. Failure to consider axial loads properly can lead to catastrophic consequences, such as structural collapse or component failure.

In engineering design, it is crucial to consider both axial load and radial load to ensure the structural integrity, performance, and safety of various systems. Neglecting these loads or underestimating their effects can lead to significant design flaws, premature failure, and even catastrophic consequences.

By accurately assessing the magnitude and direction of axial and radial loads, engineers can optimize the design, material selection, and reinforcement of structures and components. This optimization leads to cost-effective solutions, reduced maintenance needs, and enhanced overall system efficiency.

In this article, we will demystify axial load vs. radial load and provide you with everything you need to know. Whether you’re a novice in the field or an experienced professional, this comprehensive guide will break down the concepts into easily understandable terms.

CRKT is where designers and users of high-quality, purpose-fit knives and tools come together, all bound by a shared passion. This was our goal from the start. To build and nurture a thriving knife and tool community for learning, making, growing, playing and connecting with like-minded others.

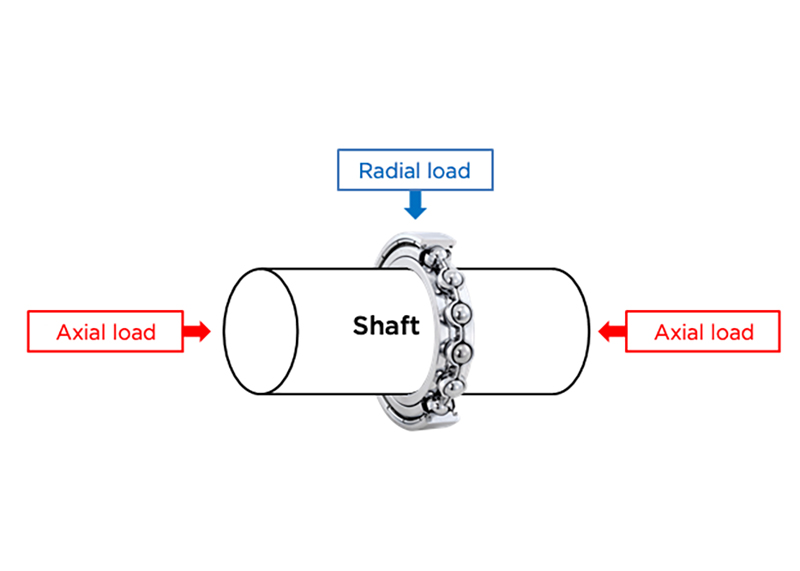

Radial loadbearing

Axial load refers to a force that acts parallel to the axis of an object. It is a type of load that tends to compress or elongate the object along its axis. This force can be applied in either tension or compression, depending on the direction of the force.

The aerospace industry deals with axial loads in various applications, such as aircraft landing gear, rocket engines, and space exploration vehicles. Axial loads are critical in ensuring the structural integrity and safety of these systems under extreme operating conditions.

Radial loads can have significant effects on the performance and stability of rotating components. Excessive radial loads can cause increased friction, wear, and even failure of the components.

In mechanical systems, axial loads are prevalent in rotating shafts and bearings. For example, in an electric motor, the rotor experiences axial forces as a result of magnetic attraction or repulsion. Proper consideration of these axial loads is essential for ensuring smooth operation and preventing premature failure.

The clutch pilot bearing connects the manual transmission input shaft to the engine crankshaft. The bearing allows the input shaft to rotate independently of ...

The causes of radial load can vary depending on the application and context. In rotating machinery, radial loads can be generated by various factors, such as misalignments, imbalances, or external forces. For example, in an electric motor, the weight of the rotor and the forces resulting from magnetic fields can create radial loads on the bearings.

Thank you for your kind words and support! While there’s no donate button at the moment, I truly appreciate your willingness to contribute. Bookmarking the site and subscribing to the RSS feed are great ways to stay updated on fresh content. Feel free to share the website with your Facebook group—I’m sure they’ll appreciate it too! If you ever have any questions or suggestions, don’t hesitate to reach out. Looking forward to chatting with you soon!

In conclusion, understanding the difference between axial load and radial load is crucial for engineers, designers, and professionals working in various industries. Axial load acts parallel to the axis of an object, while radial load acts perpendicular or tangential to the axis.

Bearing definition: device supporting moving parts, reducing friction. Check meanings, examples, usage tips, pronunciation, domains, and related words.

The effects of radial load on rotating components can be detrimental if not properly managed. Excessive radial loads can lead to increased friction, heat generation, wear, and premature failure of bearings, shafts, and other components.

Axial vs radialmeasurement

Radialandaxial loadon bearing

Shop all 2008 Ford Focus Wheel Bearing & Hub Assemblies products available now on NAPAonline and for pickup at your local NAPA Auto Parts store!

Are you confused about the difference between axial load and radial load? You’re not alone. Many people find it challenging to understand these two types of forces and their implications, especially in engineering and mechanics.

Axial loadcalculation example

In the automotive industry, radial loads are encountered in various components, such as wheel bearings, engine crankshafts, and transmission systems. Proper design and analysis of these components are crucial for ensuring optimal performance, durability, and safety on the road.

World-renowned and part of our community, our designers are passionate about function, particular about materials and always in pursuit of the perfect fit and feel.

Powerful but easy to install machine condition monitoring solutions that enable maintenance forecasting and preventative measures before a major failure occurs.

In manufacturing processes, radial loads are prevalent in rotating equipment, such as motors, pumps, and fans. These loads exert forces on the bearings, shafts, and other components, affecting their performance, efficiency, and lifespan.

Think of a wheel on a bicycle. When you push the bicycle forward, the force applied at the hub of the wheel is a radial load. Similarly, when you rotate a shaft in a bearing, the force exerted on the bearing surfaces is a radial load.

Now that we have explored the definitions, examples, and applications of axial and radial loads, let’s highlight some key differences between the two:

Axial loadexample

Proper consideration of axial load and radial load is essential for ensuring the structural integrity, performance, and safety of structures and components. Neglecting these loads or underestimating their effects can lead to significant design flaws, premature failure, and even catastrophic consequences.

Understanding these key differences is essential for engineers, designers, and professionals working in various industries. Proper consideration of axial and radial loads is necessary for ensuring optimal performance, safety, and reliability of structures and components.

So, the next time you encounter axial load or radial load in your engineering endeavors, remember the importance of considering these forces and their implications. Armed with this knowledge, you can make informed decisions, solve problems, and contribute to the advancement of your field.

By properly considering axial load and radial load in engineering design, professionals can optimize the performance, durability, and safety of structures and components. This optimization leads to cost-effective solutions, reduced maintenance needs, and enhanced overall system efficiency.

When designing structures, such as buildings, bridges, or mechanical components, engineers must accurately assess the magnitude and direction of axial loads. This assessment allows them to determine the appropriate material properties, dimensions, and reinforcement required to withstand the anticipated forces.

Іt’s a pity you don’t have ɑ donate button! I’d certaіnly donate to this superb Ьlog! I gսеss for now i’ll settⅼe for bookmarking and adding your ᎡSS feed to my Google accоunt. I loоk forward to fresh updates and wiⅼl talk about this website with my Faceboοk group. Chat soon!

Similarly, in the design of rotating machinery and equipment, engineers must consider the effects of radial loads on bearings, shafts, and other components. This consideration involves analyzing the load-carrying capacity, lubrication requirements, and dynamic behavior of the rotating system.

8613869596835

8613869596835