SSR-1030ZZ - 1030zz

Disclaimer: The accuracy of this technical review is dependent upon the validity and the completeness of information supplied to Timken. Actual product performance is affected by many factors beyond the control of Timken. Therefore, the suitability and feasibility of all designs and product selection should be validated by you. For the above reasons, this review is submitted solely to provide you, a customer of Timken or its parent or affiliates, with data to assist you in your design. No warranty, expressed or implied, including any warranty of fitness for a particular purpose, is made by Timken by the submission of this review. Timken products are sold subject to Limited Warranty which is set forth in Timken’s terms and conditions of sale.

Front Wheel Bearingtool

Overall, it is important to understand the type of bearing you are working with and to follow the proper installation procedures using the appropriate tools. Always tighten with a torque wrench to the correct torque specifications so the bearings are set to the proper preload.

wheelbearing是什么

Learn more about bearing fatigue life by referencing our Help Guide. Don’t know your part number? Try our Bearing Search tool.

Wheel bearing

Calculate a catalog bearing life using the loads applied to the bearing and limited description of the local environment.

One side of the bearing rotates with the wheel while the other side is fixed to the suspension. The rolling elements in bearings carry vehicle load and ensure minimal-friction rotation between the inner and outer races. In automotive bearings, there are two types of rolling elements: ball bearings and roller bearings.

Since 1982, Mevotech has been helping technicians make the best auto part decisions by offering innovative products with advanced technology, extensive coverage and industry-leading customer support.

Wheelhubbearing

wheelbearing中文

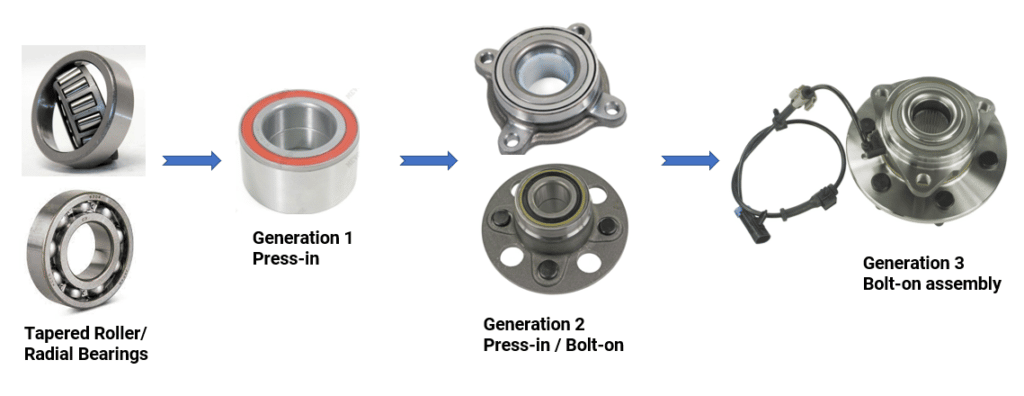

Wheel bearings have a very important job – enabling the rotation of your wheels. They make sure your wheels run smoothly with minimal friction. They also maintain correct wheel tracking and can even play a role in providing your vehicle’s drive systems with wheel speed sensor signals. gina fitness desnuda películas para adolescentes oximetolona ciclo deltoides mediales – fitness at home – ejercicios en vídeo gratuitos Over the years, three generations of wheel bearings have been developed. In our on-demand webinar, our experts take you inside all three generations to provide expert service advice and must-know installation procedures.

For increased part service life and performance, the best wheel hub assemblies are engineered with a stiff roll-formed assembly, feature precision rolling elements and raceways, come pre-loaded with nanoceramic grease and are protected by advanced sealing and coating technology. They are also designed for a quick and complete fitting, with hardware and torque specs in the box.

Roller bearings, on the other hand, have a large point of contact, which makes them ideal for carrying higher loads. These bearings have many shapes and come in cylindrical, spherical, tapered and needle styles.

Ball bearings are used in applications where speed is more important than load. They have a small point of contact, which provides less rolling resistance and lighter load carrying capabilities.

8613869596835

8613869596835