Symptoms of Bad Wheel Bearings - how long can you drive with bad wheel bearings

Increasing weight of passenger cars over the years due to improved safety equipment, increased comfort, increased connectivity are a challenge for strut and shock absorber manufacturers. Electrification will also add additional weight. GGB DTS10 - the ideal bearing solution for the new generation of suspension struts and shock absorbers. The low-friction, wear-resistant plain bearing impresses with longer service life performance and withstands increasing load conditions without increasing the size and weight of the plain bearing.

CarBearingprice

GGB’s TriboU is intended to provide the working engineer, who may or may not be a user of GGB’s surface engineered solutions, to understand and implement basic tribological concepts in the design, manufacture and use of industrial equipment.

Vehicle bearingnumber

Tribology is the science of wear, friction and lubrication, and encompasses how interacting surfaces and other tribo-elements behave in relative motion in natural and artificial systems. This includes bearing design and lubrication.

GGB tribological solutions move the industrial world one step closer to the future. Our products are used in tens of thousands of critical applications every day—around the planet. Our goal is to provide reliable, maintenance-free surface solutions for almost any application—no matter where those demands take our products.

With high toxicity levels, high costs, and more bans likely coming in the next decade —chemical conversion coatings are becoming a thing of the past. GGB polymer coatings can be an effective, environmental-friendly solution. Contact your local Application Engineer for additional information.

Car wheelbearing

Vehicle bearingreplacement

The excellent low friction and high wear resistance performance of GGB metal-polymer bearings make them ideal for hundreds of applications in numerous and diverse industries. Depending upon application requirements, metal-polymer composite bearings can be produced in many shapes and sizes.

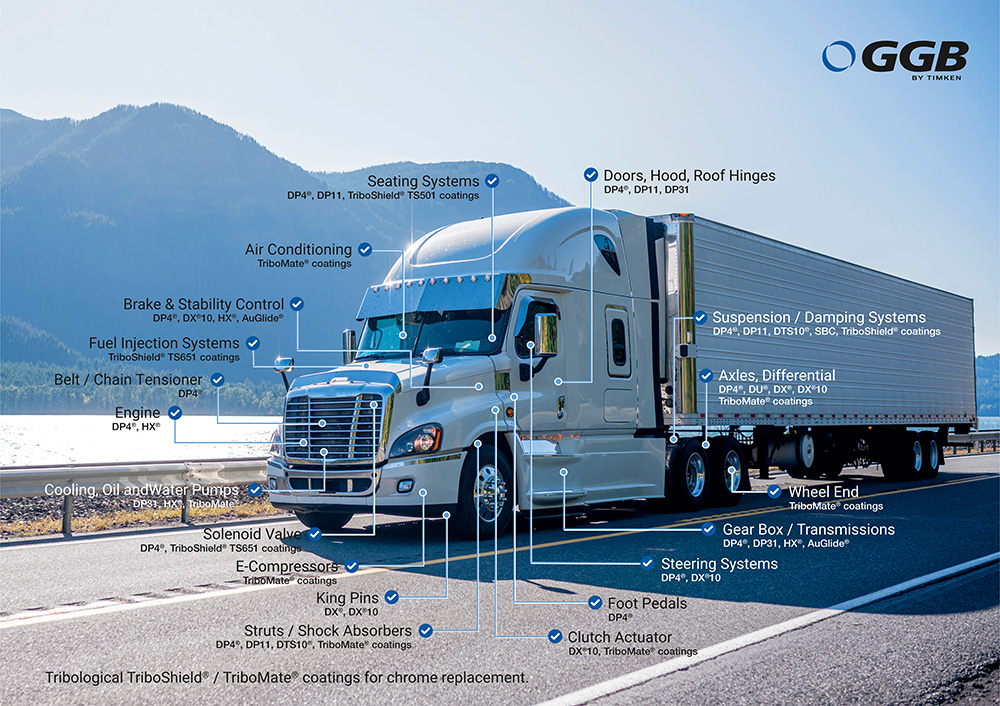

GGB doesn’t just understand the problems the automotive industry faces—we help prevent them from happening in the first place. From safety and service life issues to ride quality—GGB’s tribological solutions are designed to meet strict criteria for the design, function and performance for over 50 automotive applications—including wipers, convertible tops, interiors, struts, levers, pedals, gearboxes, solenoids and many more.

Priserna som anges i webbutiken är ikh.fi-webbutikens priser och gäller endast för beställningar gjorda via ikh.fi-webbutiken. Tillgänglighetsinformationen avser lagerstatus i ikh.fi-webbutiken. Priserna i ikh.fi-webbutiken kan skilja sig från priserna i butikerna, eftersom varje butik bestämmer sina egna priser. För information om tillgänglighet och pris i specifika butiker, kontakta närmaste IKH-partnerbutik eller IKH:s egen butik. Hitta din närmaste IKH-butik.

GGB's Engineered Plastic Polymer bearings provide excellent wear resistance and low friction in both dry and lubricated operating conditions over a wide range of applications. Engineered plastic bearings are made from thermoplastic bearing material processed by injection moulding. This production method enables us to produce unlimited dimensions in accordance to our standard, and also parts with special designs and features.

Front wheelbearingnoise symptoms

GGB can provide customers with a viable tribological solution, working alongside Tier-1 suppliers to global OEMs. Our application and tribology experts can develop a design proposal and supply samples in a shorter time than the competition, outperforming all other proposals.

How to tell which wheelbearingis bad while driving

GGB seeks out collaborative, long-term relationships with each one of our customers. Our diverse expertise gives us a deep understanding of the challenges you face. When you partner with us early, our GGB engineering team is able to review your assemblies and make sure both the bearing and surrounding components are optimized for performance and cost-effectiveness.

Engineered as a solution to conquer misalignment reduction when high demands are placed on bearings, GGB's UNI, MINI and EXALIGN® self-aligning shaft bearing assemblies offer improved equipment performance under standard bearing assemblies by reducing stress and friction. Offering superior performance in a wide variety of applications, GGB's self-aligning assemblies are available in both standard and custom configurations.

Average life of wheel bearings

At GGB, we aren’t afraid to take risks for our customers. We are passionate about the work we do and believe that same passion contributes to the level of innovation that can enhance human potential. We take pride in working closely with customers in the early stage of a design to think broadly and boldly, and to expand beyond traditional surface engineered solutions. We offer reliable partnerships based on trust, compassion, determination, collaboration and respect.

JavaScript verkar vara inaktiverat i din webbläsare. För den bästa upplevelsen på vår webbplats, bör du aktivera Javascript i din webbläsare.

IKH-partners:Alajärvi, Alavieska, Alavus, Enontekiö, Eura, Forssa, Haapajärvi, Haapavesi, Huittinen, Hyvinkää, Iisalmi, Imatra, Isojoki, Ivalo, Joensuu, Jomala, Jämsä, Kajaani, Kalajoki, Kangasniemi, Kankaanpää, Kannus, Karjaa, Kauhava, Kaustinen, Kemi, Kemijärvi, Keuruu, Kinnula, Kitee, Kittilä, Kiuruvesi, Kokkola, Kolari, Kotka, Kouvola, Kuhmo, Kumila, Kuortane, Kuortti, Kurikka, Kuusamo, Lahti, Laitila, Lapua, Lieksa, Lohja, Loimaa, Loviisa, Mikkeli, Muhos, Muonio, Mynämäki, Mäntsälä, Nilsiä, Nivala, Nuorgam, Nurmes, Orimattila, Orivesi, Oulainen, Parkano, Pieksämäki, Pielavesi, Pietarsaari / Jakobstad, Pihtipudas, Porvoo, Pudasjärvi, Pulkkila, Punkalaidun, Pyhäjoki, Pyhäsalmi, Raahe, Ranua, Rauma, Rovaniemi, Ruovesi, Ruukki, Saarijärvi, Salo, Sastamala, Savonlinna, Seinäjoki, Siilinjärvi, Sodankylä, Somero, Sotkamo, Suomussalmi, Suonenjoki, Tammisaari, Tervajoki, Tornio, Turku, Tuuri, Uusikaupunki, Vaasa, Valkeakoski, Varkaus, Viitasaari, Virrat, Vörå / Vöyri, Ylitornio, Ylivieska, Ähtäri, Äänekoski

IKH:s egna butiker:Birkala, Björneborg, Esbo, Helsingfors (Kånala, Kasåkern), Jyväskylä, Kauhajoki, Kuopio, Kouvola, Rovaniemi, Tammerfors (Lielax), Tavastehus, Uleåborg, Vanda, Villmanstrand

Wheelbearingreplacement cost

Bimetal and metal bearings offer excellent corrosion resistance in industrial outdoor applications and in water, marine and offshore environments. GGB offers a broad range of sizes, forms and materials in monometallic and bimetallic bearings.

Your business depends on the reliability and performance of your vehicles. With the demands for noise reduction, electrification, autonomous driving and comfort, automakers need to look at every component of their vehicles for potential weight and space savings. GGB bearings and surface solutions not only meet strict criteria for the design, function and emissions, they also help make your vehicles safer and more reliable with better fuel economy. Add it all up and it all translates to customer satisfaction.

GGB has been putting the world in motion for over 120 years with industry-leading tribological bearings, coatings and assemblies. From Polymer Coatings and Metal-Polymer bearings to Fiber Reinforced Composite bearings and self-aligning shaft bearing assemblies, our solutions are specifically designed to reduce friction and optimize performance and durability.

GGB's Fiber Reinforced Composite products typically consists of a filament-wound, fiberglass-impregnated, epoxy backing with a variety of low-friction wear-resistant bearing linings. These self-lubricating fiber reinforced composite bearings are particularly effective in applications where the relative motion is not sufficient to promote circulation of the oil or grease used with more conventional bearings. GGB Fiber Reinforced Composite bearings are available as bushes, plates, bearing segments and special forms, depending on the particular material type.

GGB's diverse polymer coating solutions encompass some of the most state-of-the-art coating technologies available. Our TriboShield® product line includes seven standard formulations that cover the full spectrum of mechanical, thermal and chemical capabilities offered by today's coating materials. They can also be applied to nearly any surface, regardless of shape or material, making their potential almost endless. And when it comes to working with and enhancing the performance of your existing bearing and polymer coatings solutions, our TriboMate product line is specifically designed to be paired up— all leading to enhanced performance.

8613869596835

8613869596835