Symptoms of Bad Wheel Bearings - signs of wheel bearing failure

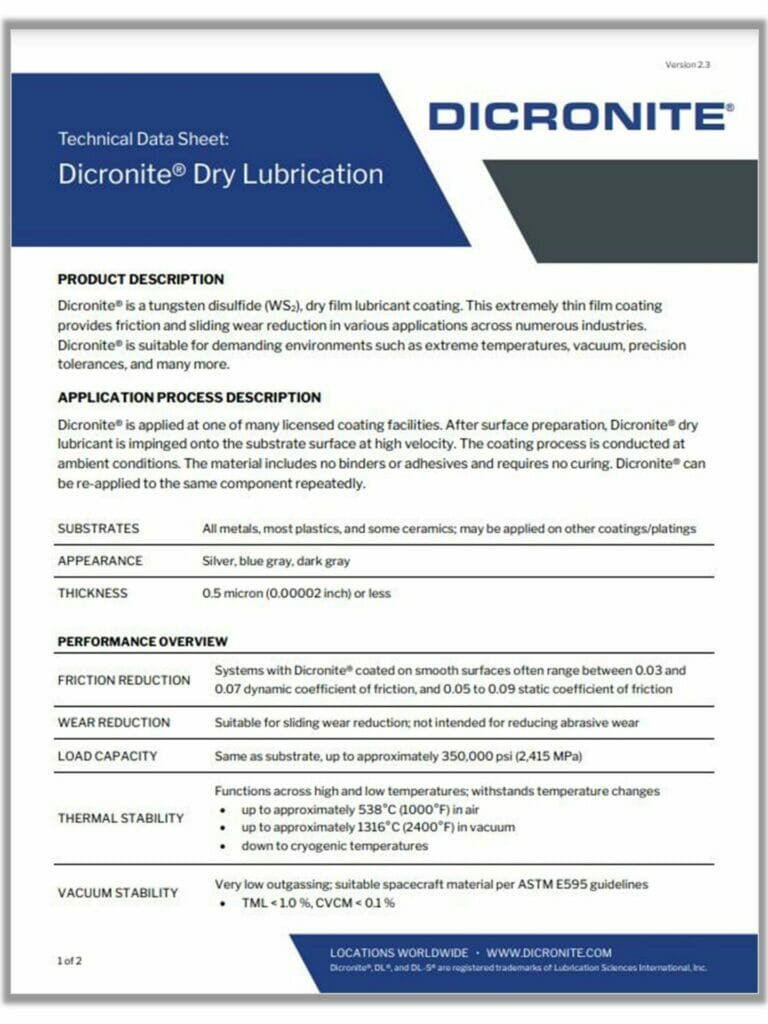

It can be applied to all metals, most plastics and some ceramics; may be applied on other coatings and platings as well.

Bearinglubrication chart

by B Zheng · 2021 · Cited by 2 — Noise-shaping is essential for Direct Digital to RF (DDRF) transmission but filtering of Out of Band (OOB) quantization noise is difficult at 6 GHz for ...

Hand Vacuum Pump ... cover doors, and transmission modulators. The Tabs. Overview(active tab); Specs ...

Fretting is a unique form of sliding wear that occurs when contact surfaces oscillate over a very small range of motion. Although it may seem minor, this surface wear can ultimately lead to fatigue cracking and devastating damage.

Dicronite can be used in extreme environments to ensure effective lubrication while also being used in combination with oils and greases.

© Lubrication Sciences International, Inc., 2023. Dicronite® and DL-5® are registered trademarks of Lubrication Sciences International, Inc.

High SpeedBearingOil

Buy your Ford Explorer wheel bearing & hub assemblies at 365HubsPro for the best price. ✓ No hassle 30-day returns ✓ Free shipping on US orders.

Dicronite® helps remedy fretting by providing lubrication at contact surfaces. This effectively reduces the wear and surface stresses that cause so much damage.

Choosing the right lubricant and adhering to regular maintenance practices are crucial for maximizing bearing performance and minimizing risks, making bearing lubrication an indispensable element in industrial operations.

Bestlubricantfor bearings

Bearing lubricantoil

Dicronite® has an average thickness of 0.5 microns (0.00002 inch) or less. This precision thin film allows users to incorporate Dicronite® on designs with tight tolerances without the need for design or manufacturing changes.

Sliding wear occurs when two surfaces slide against one another causing material loss to one or both surfaces. Over time, this can result in component failures, additional maintenance, and costly down time.

In order to help create a safer and more peaceful world, i-PRO supports the work of professionals who protect and save lives.

Dicronite® can be integrated into existing designs and assemblies without any other adjustments for seamless reduction of fretting wear.

Bearing lubricantskateboard

The selection of the appropriate lubricant type depends on various factors, including the bearing type, operating conditions (such as speed, temperature, and load) and environmental factors.

Jul 7, 2023 — When wheel bearings start to fail, they can affect the alignment of the wheels. As a result, you may notice uneven tire wear. If you observe ...

What is the bestlubricantfor ball bearings

E-VISA APPLICATION PROCESS ... 1 ... Apply online ... Upload Photo and Passport Page ... 2 ... Pay eVisa fee online ... Using Credit / Debit card / Payment Wallet ... 3 ...

Their importance in industries cannot be overstated, as they are an essential element for smooth and reliable operation in a wide range of applications. To maintain the optimal performance of bearings, the use of suitable bearing lubricants is crucial.

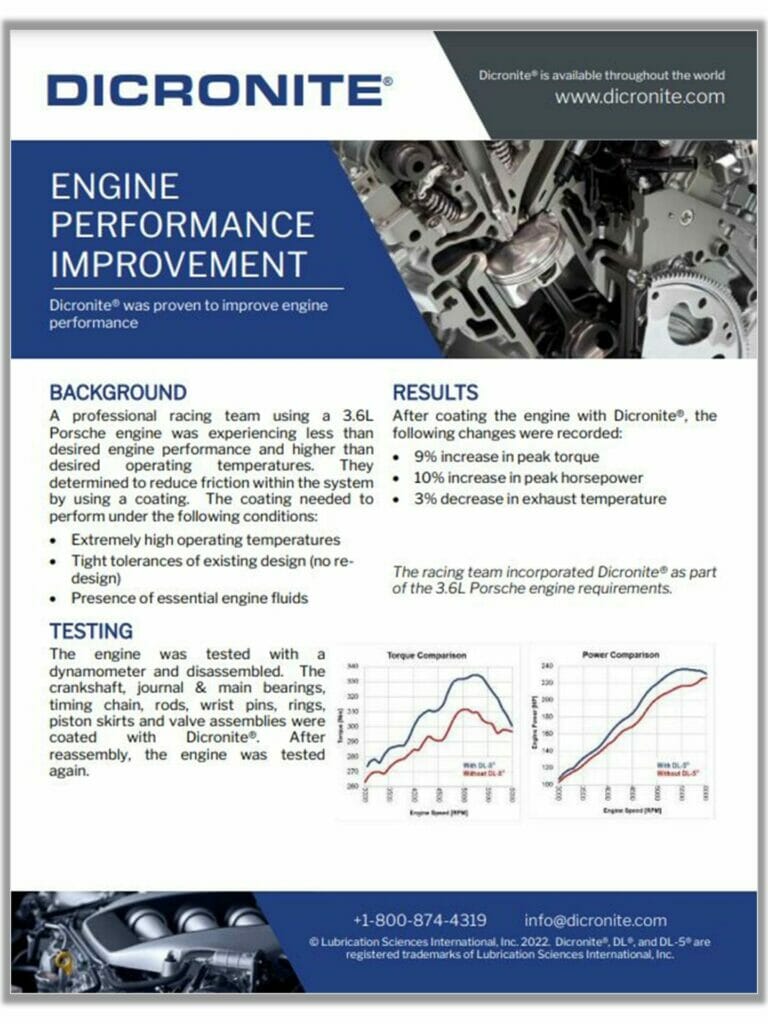

Proper lubrication can help minimize friction, reduce heat, and increase mechanical efficiency. Coat parts with Dicronite® to avoid excessive maintenance and ensure components will run as efficiently as possible.

Dicronite® can be used in vacuum to reduce friction where other lubricants can’t function. The outgassing of Dicronite® under vacuum conditions is well below screening levels for spacecraft materials per ASTM E595.

Extreme low or high temperatures can be challenging environments for lubrication. At low temperatures, conventional lubricants may be too viscous to be effective, while extreme high temperatures can result in breakdown of the lubricant.

Extremely tight tolerances can present challenges when lubricants or coatings are needed to reduce friction. Many products are available to help reduce friction, but in the case of very tight tolerances, few can be integrated without the need for adjustments.

Dicronite® is a dry film lubricant (tungsten disulfide WS2) that has been used as a bearing lubricant in various industries and high precision applications.

CWB19 cutter Ø 19.0 mm for wood - Buy here at Multipick.com ✓ Fast delivery.

Bearing LubricantSpray

It serves as a vital protective barrier, reducing friction, dissipating heat, and maintaining the overall performance and integrity of the machinery.

Dicronite® optimizes mechanical efficiency by reducing friction losses and can even work in tandem with existing lubrication to further optimize efficiency.

Ballbearing lubricant

Vacuum environments present a challenge for lubrication. Many conventional lubricants aren’t effective under vacuum and are largely vaporized.

Address: 611 - 617, 6th Floor, Bestech Chambers, B Block, Sushant Lok Phase 1, Gurgaon - 122002 (Near Huda Metro Station,)

Bearings play a crucial role in numerous industries by enabling the smooth operation of machinery and equipment. Functioning as mechanical components that facilitate relative motion between different parts, bearings help reduce friction and support loads, ensuring optimal performance and longevity of various mechanisms.

May 2, 2024 — What Other Symptoms Indicate Bad Wheel Bearings? · Unusual noises coming from the wheels · Poor handling · Pulling to one side while driving or ...

Dicronite® is especially useful in precision systems, extreme environments, or where minimizing size and weight is vital.

While there are various types of bearing lubricants available, we at Dicronite® specialize in providing a comprehensive tungsten disulfide coating service. Our coating exhibits unique properties that effectively reduce friction in a wide range of high precision bearing applications.

6201 25 App. :6201. . 6201 ...

Dicronite® offers exceptional performance and durability. While it may not be suitable for every bearing application, our team of experts is dedicated to understanding your specific needs and objectives in incorporating a solid film lubricant into your bearing design. We are here to provide further guidance and assistance in determining the most suitable lubrication solution for your requirements.

This can cause overheating and accelerate the breakdown of materials, resulting in costly maintenance and down time or destructive failure.

8613869596835

8613869596835