Tapered roller bearings (TRB) | C & U ... - tapered bearing

wheel bearing中文

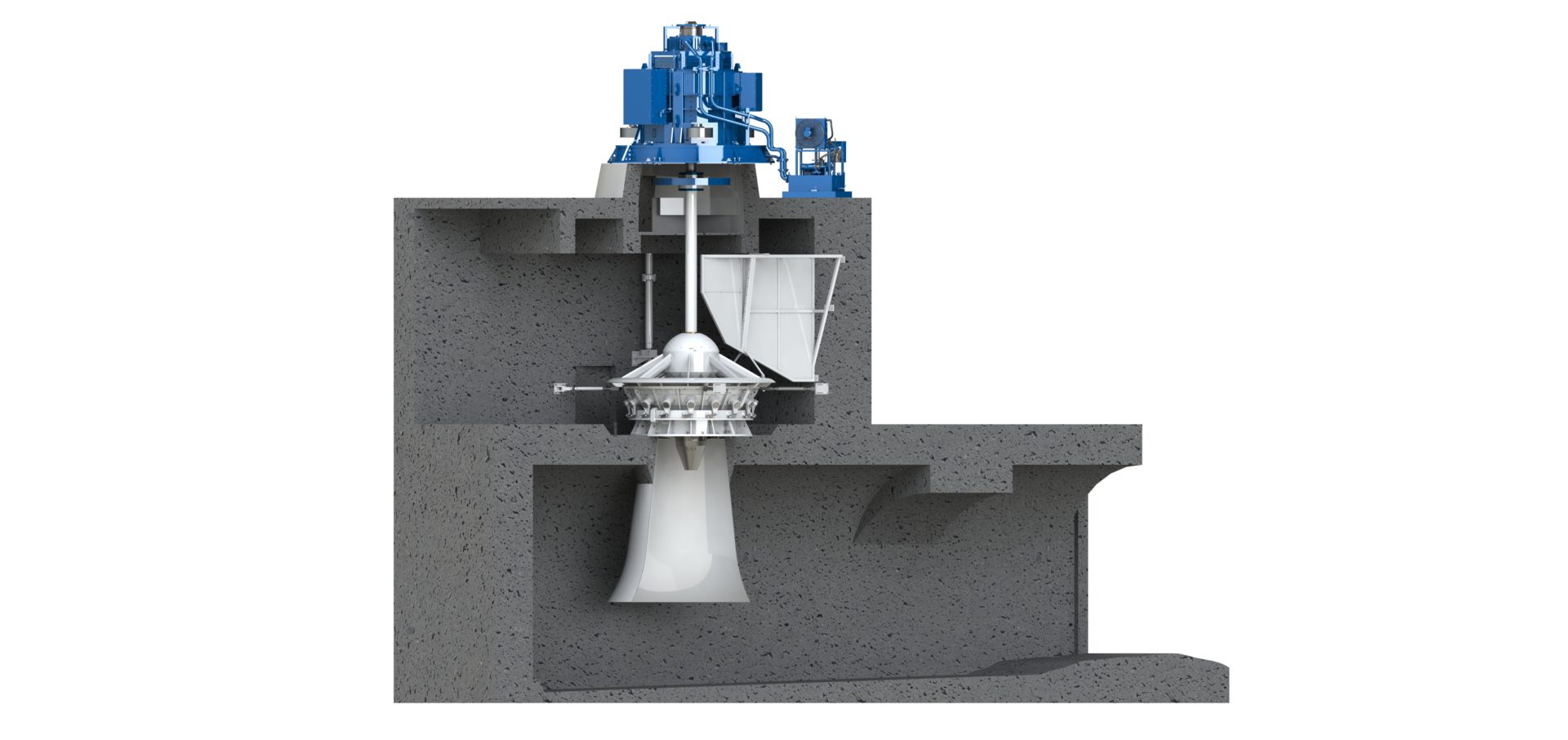

Since 1992, Norcan has been a leading Canadian manufacturer of turbines and their components. We have a high level of expertise on all types of turbines in the range of 200 kW to 30 MW. We are located in Carleton Place, Ontario, Canada. Canadian and American customers value the local proximity of our engineering resources, field services, and manufacturing facilities because it reduces overseas logistical risks.

wheel hub中文

We at Grand River Conservation Authority have been very satisfied with the Norcan equipment and working relationship with Norcan staff. There are Norcan turbines installed at two of the site where GRCA produces hydro, we are impressed with the quality of their product and their commitment to ongoing customer service and support. Simply put they stand behind their product and that’s appreciated.

Wheelbearing

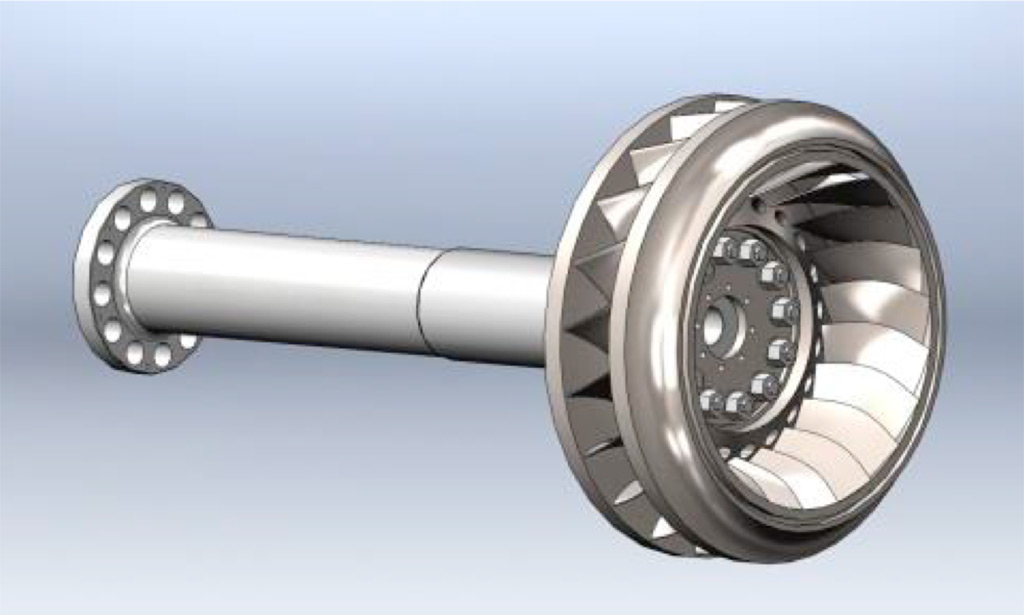

In 2013, Norcan acquired from Barber Hymac Hydro all of their Barber turbine design and data assets. These assets included turbine design, OEM parts design, and specifications. Norcan is ready to perform all necessary repairs, replacements, or upgrades with newer technology and improved efficiencies on all Barber Francis, S-Type, and Kaplan turbines.

WheelBearing and Hub Assembly

Our city council actually applauded when I told them the modernized unit would get there in February, great job on expediting from your end! Pelican Hydropower Station 600kW

Front WheelBearing

wheel bearing是什么

Customers trust Norcan with the installation and commissioning of turbines and their components. This trust has been gained through Norcan’s ability to complete complex projects efficiently and safely. Hydropower owners don’t have to worry when Norcan is involved.

Modernization projects with Norcan are a win-win-win investment. Revenues are maximized, the life of the assets are extended and the project is in expert hands.

Pump-As-Turbine (PAT) is an alternative to custom hydro turbines for micro and small hydro projects. However, as an inverted submerged pump acting as a turbine, a PAT is prone to severe cavitation. Norcan has developed a significant game changer in the modernization of existing PAT equipment.

Hydropower stations are significant assets for their owners. They must remain online in order to maximize revenues. Modernizing an old hydropower plant aims to mitigate the effects of aging on efficiency and reliability.

Quality is the focus of our shop assembly and factory acceptance testing. High levels of quality are maintained through approved processes. It does not matter if the part is made in-house or supplied to us by one of our qualified vendors. Before their use in an assembly, all parts are thoroughly inspected.

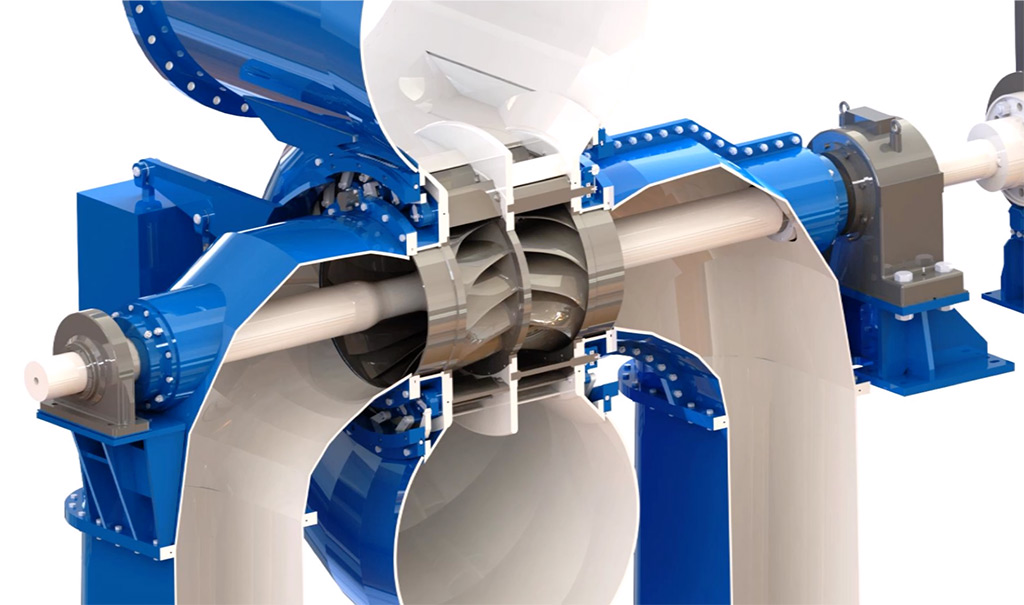

Norcan can convert a station from an old propeller turbine to a Kaplan turbine. This conversion has numerous benefits to the power plant owners. No structural changes to the power station, very little civil work to install the wicket gates’ regulation, and the turbine runner diameter remains the same.

Wheelhub assembly

Bracebridge Generation has been a customer of Norcan Hydraulic since 2005 and we currently own 6 Norcan units totaling 16.5 MW. Norcan worked very closely with us in these 5 redevelopment projects and they were extremely responsive to our needs. Timelines were always met, costs were within budgets and unit performance met or exceeded expectations. Norcan’s customer service is exemplary and they are a pleasure to work with.

Wheelhub bearing

Norcan is your single source of complete hydropower plant engineered solutions from the water connection to the grid wires for your station modernization, or greenfield project. Norcan provides, with their suppliers, the complete mechanical balance of plant, electrical balance of plant, electrical solutions, and services for your hydropower station.

We at Gemini Power Smooth Rocks Falls Project 10.9 MW have been extremely pleased with all aspects of our relationship with Norcan Hydraulic Turbines, including original equipment design and manufacture, quality & cost control, timeliness of supply, experienced field erection services, technical advice, and support, as well as after commissioning follow up support.

It takes experts to successfully modernize an old hydropower station. Norcan has over 30 years of experience in modernizing stations, a strong reputation, and a proven track record of projects delivered on time. Customers benefit from our strong team of engineers, project managers, manufacturers, and field services.

Hydropower stations are significant assets for their owners. They must remain online in order to maximize revenue. Modernizing an old hydropower plant aims to mitigate the effects of aging on efficiency and reliability.

8613869596835

8613869596835