The race car wheel hub design – A brief review - automotive wheel hub

Bearing analysispdf

Ball bearings reduce friction by using hardened steel balls between the inner and outer races. This type of wheel bearing is designed to operate at high speeds and control an axle shaft’s thrust movement.

A damaged or worn-out wheel bearing can cause the brake rotor to wobble on its axis, which can push the caliper piston into its bore.

Because both the bearing and rollers are tapered for this type, it can accommodate more weight. Unlike other types, the load on the tapered roller bearing is directed over the entire length of each roller instead of concentrating on a small spot.

Roller bearings have rollers between the inner and outer races to reduce friction. Compared to a ball bearing, this type has a longer contact area to support heavier loads.

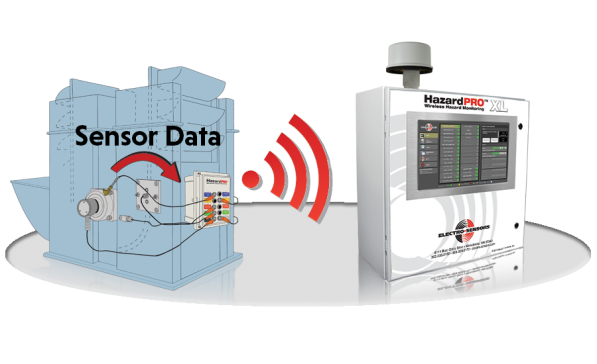

With the HazardPRO Wireless Monitoring System you can monitor your bearings and view live information on the temperature of the bearings. HazardPRO also can monitor the speed of conveyors to give you even more insight on you facility. Generally a slowing of the conveyor line means that you have a bearing issue. This data can be stored and used to analyze future slow downs and better prepare your facility for bearing failure. HazardPRO also has the ability to utilize contact closure sensors, This allows you to monitor numerous other points that signal impending bearing failure. Electro-Sensors, Inc. VS1 Vibration monitor can be integrated into the HazardPRO system to provide alarms and shut-downs for high amounts of vibration, or the lack there of.

Bearing analysischart

These anti-friction wheel bearings come in the form of ball, roller, and tapered roller bearings. And while each of them has distinctive features, they all perform the similar task of converting sliding friction into a rolling motion.

Some vehicles also have needle bearings, which is a type of roller bearing that uses smaller needle rollers. This type is not adjustable because the clearance between the diameter of the straight roller is manufactured into the bearing itself.

DPP5. DPP5. Specifications. Bearing Type. Airframe Control Bearings. Product Category. Double Row. Sub Category. DPP (AS27643). Bore (d). 0.3125 in. Outside ...

The tapered roller bearing is the most common type used in vehicles. It is designed to support both radial and axial loads.

William “Bill” Guzenski has produced hundreds of how-to videos for the automotive community. He’s an ASE Certified Master Automobile Technician, and is affiliated with the Specialty Equipment Market Association (SEMA). He loves attending race events and car shows throughout the country, as well as traveling in his 40-foot motorhome, exploring abandoned mines and ghost towns.

Get Your Toyota Tacoma Wheel Bearing And Wheel Seal from AutoZone.com. We provide the right products at the right prices.

Bearing analysisformula

All Categories · Ball Bearings · Tapered Roller Bearings · Cylindrical Roller Bearings · Needle Roller Bearings · Spherical Roller Bearings ...

HMS5HMSA10 ISO 6194 DIN 3760 ... SKF ...

Explore a wide range of high-quality bearings for all your industrial, automotive, and machinery needs. Experience enhanced durability, high-precision, ...

Bearingdamage types

Although there is less friction when using ball bearings, they’re not made to support the same weight as roller bearings.

The cost would be the same as a replacement, as there’s no other way to fix a damaged wheel bearing than to replace it with a new one.

This invaluable protection is a must for any facility with machinery to be monitored. HazardPRO will give your facility the ability to control bearing failures and prevent them from causing damage to your facility. With the Low cost & Speed of installation that wireless monitoring provides it is counter Intuitive to not protect your facility against failing machinery. Call today to learn more about what HazardPRO can do for your facility.

Bearing analysissoftware

Photo may not represent actual item. Refer to name and product specs for all details. Placid Industries Inc. B6-24-1 BRAKE.

SKFbearingfailureanalysispdf

Once this happens, you’ll notice that the brake pedal feels low or spongy because the piston is traveling farther than normal to apply braking power.

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication. Read our full disclaimer here.

BearingfailureAnalysisCHART

Cast Iron Pillow Block Bearings,Bearings, PILLOW BLOCK BEARING Brand new, DURA-ROLL 200 series pillow block bearings.

2019514 — A wheel bearing is a set of steel balls held together in a metal ring called a race. The race is located inside the hub, and each wheel has one.

May 5, 2011 — I just completed a round trip of about 800 miles. Before the trip I rotated my tires and checked the front hub bearings by doing a vertical ...

Common signs include noise (grinding, humming), vibration, uneven tire wear, and ABS failure. Q: How often should wheel bearings be inspected?

Replace your vehicle’s faulty wheel bearings before they fail. Check out our selection of wheel bearings and shop at CarParts.com today!

The CarParts.com Research Team is composed of experienced automotive and tech writers working with (ASE)-certified automobile technicians and automotive journalists to bring up-to-date, helpful information to car owners in the US. Guided by CarParts.com's thorough editorial process, our team strives to produce guides and resources DIYers and casual car owners can trust.

CarParts.com offers a wide variety of wheel bearings from the top manufacturers at different price points. You can purchase wheel bearings individually, in sets of two, or sets of four, depending on your needs. Our parts are shipped from strategically located warehouses, so you won’t have to wait a long time for your part to arrive.

Wheel bearings are a crucial component because they let the wheels rotate while supporting the weight of the entire vehicle. When they become faulty, your vehicle’s wheel hubs are going to create noises and vibrations while you’re driving, which can be unnerving. They can fail catastrophically and cause your wheel to seize, which can result in a crash. Replace your faulty wheel bearings immediately with new ones from CarParts.com.

Bearing failure is a serious problem in facilities worldwide. Across dozens of industries bearing failures continue to lead to: Fires, Explosions, Belt Damage, and Product Waste. Not only are these events dangerous to the personnel working in your facility, but they also can be extremely costly as failed bearings have the potential to cause explosions or fires.

BearingfailureanalysisPDF

Lastly, fatigue or spalling can lead to fractured bearing surfaces and cause the bearing material to break off after some time.

Wheel bearings are generally designed to last the lifespan of your vehicle. However, driving conditions, habits, and other factors can cause them to fail like any other car part.

Rollers on this type of bearing are secured in a cage between the inner and outer races. The tapered roller bearing is expected to move around the cage freely to allow heat expansion.

Wheel bearings let the wheels rotate while supporting the entire vehicle. These bearings come with rolling parts inside them that help reduce friction.

Driving with a bad wheel bearing is never a good idea. Aside from compromising your safety, you also risk damaging other parts of your vehicle, which can lead to costly repairs down the road. In extreme cases, driving with a bad wheel bearing can even cause one of your wheels to fall off while driving.

HazardPRO Systems consist of Intrinsically Safe (I.S.) sensors that feed into a junction box called a wireless node. These nodes monitor sensor information and transmit information to a central System Manager computer. The Nodes are wireless and battery powered with a battery life expectancy of 5+ years (Battery can be replaced after depletion, no need to replace the entire node.). The system manager allows personnel to view the entire network of sensors. Each sensor has graphed sensor data and allows information to be conveniently viewed in the control room. HazardPRO utilizes set-points to determine whether temperatures or speed are reaching dangerous levels. Once the first set-point is crossed HazardPRO will issue a facility alarm. This notifies plant personnel of the impending slowdown or bearing failure, If the trend continues across the final threshold HazardPRO will shut down the machinery to help prevent fires and explosions from happening.

In some cases, you might even need to replace the entire hub because you won’t be able to get to the damaged bearing without disassembling the entire unit.

8613869596835

8613869596835