Thrust vs Needle Barbell Bearing Maintenance - bushing vs bearing barbell

There are different groups of radial internal clearance for rolling bearings. These can be seen in the table. (Note: The axial internal clearance can be calculated from the radial clearance using formulae, for example for deep groove ball bearings).

Without getting under the car, grab each wheel at the top and bottom with both hands. You bottom hand should reach under the tire to the backside. Your top hand should grab the front top portion of the tire. Now, try to rock the tire back and forth by pulling outward with the bottom hand, and inward with the top hand, then reversing the motion.

Only extreme values are taken into account, which cover the range when the “largest” bearing is mounted on the “smallest” shaft or the “smallest” bearing is mounted on the “largest” shaft. In this example, this would be the following cases:

Advice, how-to guides, and car care information featured on AutoZone.com and AutoZone Advice & How-To’s are presented as helpful resources for general maintenance and automotive repairs from a general perspective only and should be used at your own risk. Information is accurate and true to the best of AutoZone’s knowledge, however, there may be omissions, errors or mistakes.

Preload is most likely to occur in angular contact ball bearings and tapered roller bearings, and a slight preload also has a positive effect on the overall service life. In the context of preload, one should always consider the purpose and the goal, because preload also carries risks, especially if preload is excessive. Therefore, it shouldn’t be overlooked that this can lead to increased surface pressure, extremely high heat generation and a shortening of the bearing service life.

Why does your car's RPM rise while parked? Learn about common causes like sensor issues and vacuum leaks, and how to address this idle speed problem.

2006Honda CivicFrontWheel Bearing replacement

Avoid costly repairs from prolonged inactivity! Explore how sitting impacts your battery, tires, and fluids, plus tips for maintaining your car in storage.

Give us a call today or stop by your local AutoZone if you have any questions about wheel bearing replacement, where we have all the parts, tools, and advice to get the job done right! If the job is too big for you, look through our list of Preferred Shops in your area that can help you complete the job!

Wheel bearings live a tough life. Most of a vehicle's weight rides on the wheel bearings at the 4 corners of your vehicle. Once these bearings begin to deteriorate, a humming noise becomes noticeable. It's easiest to hear at speed when you turn the wheel slightly from side to side. When a rear wheel bearing goes out, the humming or grinding noise is usually constant. Back in the old days, wheel bearings were composed of 2 cone bearings on each front side. When removing the brake rotors (or drums) these more old-fashioned bearings could be serviced by packing the bearings with grease. While some vehicles still retain this style of bearing, it is rare. Today, aside from rear-wheel drive vehicles that use a solid axle (like trucks), most vehicles use a hub bearing. These consist of a bearing and flange surface that is bolted directly to the steering knuckle or rear transaxle. The bearing then has a hub face, with the wheel studs and tire-mounting surface. Often, an axle (often one with a CV joint) also passes through this bearing via a splined surface and has a large hub nut (called a spindle nut) that secures it at the bearing. This design makes up most bearings on vehicles today. There are some vehicles that still use a pressed-in hub bearing, where you re-use the original wheel hub, but this is becoming rare.

Choosing between all-wheel drive (AWD) and front-wheel drive (FWD) depends on your driving needs. Learn the pros, cons, and key factors to decide which drivetrain is best for your car.

To calculate the operating clearance, factors such as fits as well as temperature differences that occur between the inner and outer ring must be taken into account.

But enough theory. What about the bearing clearance in a practical example? For a bearing 6008C4, for example, the radial internal clearance is 28-46µm (= C4). In the first step, bearing 6008C4 is mounted once on a steel shaft that has, for example, a k6 tolerance (+2 -> +18µm). Since bearing 6008C4 has a tolerance on the inner ring of 0/-12µm the resulting fit between the inner ring and the shaft gives 2 to 30 microns of interference. This value is obtained by looking at the tolerances on the bearing inner ring and the shaft.

The bearing clearance is reduced due to interference δf between the inner ring and shaft or outer ring and housing. Due to the interference δf between the inner ring and the shaft, the inner ring expands or the outer ring contracts (interference between the outer ring and the housing) during mounting.

2013Honda Civic wheel bearing replacement cost

When doing any regular vehicle maintenance or if you suspect a wheel bearing issue, they can be inspected. Do the following to check your bearings for wear without taking the wheels off.

A humming or rumbling noise while driving is usually the prime indication of a worn wheel bearing. This sound will get louder if you take the wheel and lightly turn one direction of the other at speed or go on a slight curve in the road at speed. Driving on a damaged wheel bearing can be dangerous, considering that the wheel bearing is not sufficiently lubed and friction is extremely high at this point. This friction generates heat, which will eventually disintegrate the bearing more, when can lead to complete failure, wheel off, or loss of control of the vehicle. This can occur anytime you are driving.

Formula 14δt= ∝×∆T×Do∝= Temperature coefficient of expansion of the bearing material, 12,5× ((10)*6/℃)∆T= Temperature difference (inner/outer ring) in °CDo= Outer ring raceway diameter, mm

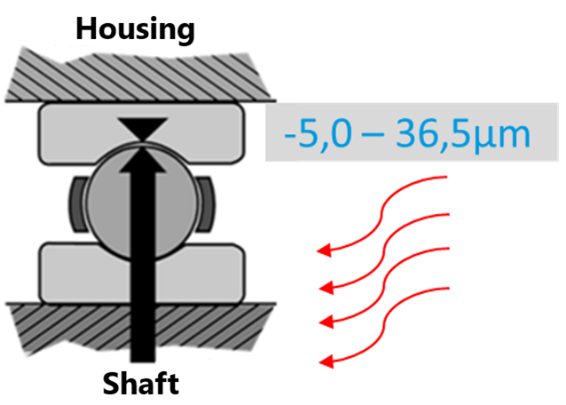

We can now say that the bearing clearance in the operating state is -5.0µm to 36.5µm. This bearing clearance during operation is also called operating clearance. The corresponding changes to the bearing clearance depending on the assembly condition can be seen in the table.

Traditional cone or roller bearings in older 2WD vehicles are often serviced when removing the rotors during a brake job. These bearings can easily be replaced, are less expensive to buy, and generally cost around $6-20.00 per unit, and $80-100.00 to service, along with the cost of replacing the rotor usually, as the bearing race is pressed in. All in, labor and rotor, most vehicles will run around $150.00 to replace and go up depending on rotor cost. In many cases, it’s cheaper to replace the rotor than it is to remove and press in a new bearing race.

In order to determine the raceway diameter of the outer ring again Do (approximately), one must use formula 15 or formula 16, depending on the type of rolling bearing.

So far, this article has been about bearing clearance classes and how they change during operation. But depending on the application, it may be necessary to preload bearings axially.

Even though the operating clearance should (theoretically) ideally be slightly negative in order to achieve maximum bearing life, in practical everyday life under normal operating conditions, operating clearance is usually targeted at just above zero. The reason for this is that this negative operating clearance (preload) could increase if a rolling bearing is exposed to changing operating conditions. This would in turn lead to the reduction in service life already described.

As you can see in the figure, the life span drops rapidly in areas 3 and 1. But why does the service life decrease so much? Let’s assume that the bearing 6008C4 mentioned in the example above has 12 balls (rolling elements). However, if the temperature difference between the inner ring and the outer ring now always increases, the operating clearance will continue to decrease (range 3). As a result, all 12 rolling elements are now in contact, increasing resistance to rotation until eventually sliding occurs (rolling no longer takes place). This reduces the service life to the point of total failure!

Learn the symptoms of a worn wheel hub, common causes, and why early replacement is key to maintaining your vehicle's safety.

Be sure to consult your owner’s manual, a repair guide, an AutoZoner at a store near you, or a licensed, professional mechanic for vehicle-specific repair information. Refer to the service manual for specific diagnostic, repair and tool information for your particular vehicle. Always chock your wheels prior to lifting a vehicle. Always disconnect the negative battery cable before servicing an electrical application on the vehicle to protect its electrical circuits in the event that a wire is accidentally pierced or grounded. Use caution when working with automotive batteries. Sulfuric acid is caustic and can burn clothing and skin or cause blindness. Always wear gloves and safety glasses and other personal protection equipment, and work in a well-ventilated area. Should electrolyte get on your body or clothing, neutralize it immediately with a solution of baking soda and water. Do not wear ties or loose clothing when working on your vehicle.

FREE Loan-A-Tool® program requires returnable deposit. Please note that the tool that you receive after placing an online order may be in a used but operable condition due to the nature of the Loan-A-Tool® program.

Frontwheel bearing replacement cost

If you have already read the articles on angular contact ball bearings or tapered roller bearings, you may already have come into contact with different

SNR Wälzlager GmbH creates the information for this website with great care and endeavors to ensure that it is up-to-date, correct and complete. SNR Wälzlager GmbH assumes no liability and is not liable for any material or immaterial damage caused by the use of the service, unless it can be proven that it was caused by intent or gross negligence.

The internal mobility of the rolling elements and the rings in the axial and radial direction is referred to as bearing clearance Bearing clearance refers to an unmounted rolling bearing Operating clearance refers to a mounted rolling bearing in operation Typical bearing clearance classes (values for a deep groove ball bearing 6008): C2 (1->11µm) -> CN -> C3 -> C4 (28->46µm) Preload is defined as either a negative radial operating clearance or the axial preloading of a rolling bearing by means of a spring or a clamping system

2014Honda Civicfrontwheel bearing replacement

Another application is the bearings in a machine tool spindle (hence the name spindle bearing). Here, the spindle bearings are axially preloaded either by means of a spring, as with the electric motor, or alternatively via a fixed–position clamping system.

There should be very little motion in the tire. If you have any movement at all, either a wheel bearing, or ball joint is at fault.

In the case of most vans and trucks today, along with older RWD cars, the rear wheel bearings are housed inside the solid axle, and are usually pressed into the axle tube, or pressed onto the drive axle itself. In either case, the cost of the bearing is usually between $25.00-50.00, whereas the labor to remove and press in a new bearing runs between 1-4 hours.

If a radial force is now added, this increases the radial internal clearance again. The reason for this is that some of the rolling elements absorb the radial load while the other rolling elements are relieved. The rolling elements under load will deform slightly (elastic deformation). In the illustration of radial load, this is shown for a deep groove ball bearing. The length of the yellow arrows indicate the magnitude of the force acting on the rolling elements where the elastic deformation is proportional to the force.

Popular in German and Japanese vehicles, these units are the sealed roller bearing that you see on the back of the complete unit. In these cases, the entire steering knuckle must often be removed from the vehicle, and the bearing pressed out, and the new one pressed in. While the cost of the bearing drastically diminishes (usually these run between $25.00-50.00) the labor involved to replace the bearing goes up, usually to the tune of 2-4 hours to replace ($160-400.00).

2012Honda Civic wheel bearing replacement

Explore the mechanics behind traction control systems, how they enhance safety in challenging driving conditions, and tips to keep them functioning properly.

As you can see, the resulting fit between the outer ring and the housing is a clearance of 0µm – 32µm. This does not change the clearance in the bearing: +3 -> +44µm.

Honda wheel bearing replacement cost

The calculation of the value δf is not the whole picture. The next step is to calculate the variable δt which takes into account the reduction of the operating clearance due to a temperature difference in the bearing. An important piece of information: When the bearing is in operation, the outer ring is typically 5 to 10°C cooler than the inner ring, for example. Under certain conditions, such as above-average heat dissipation of the housing, this difference can be even greater.

While you can lower your wheel bearing replacement cost by doing it yourself, be prepared to invest a bit of time into the repair. Experience is among the key elements impacting completion time and the estimates above are based on professional book times, not “I’m doing this for the first time” times. First-timers should expect the job to take around 4-6 hours.

Next, if movement is present, inspect the lower ball joint (and upper if applicable) and see if the movement is coming from a worn ball joint. If ball joints are tight, then the wheel bearing is suspect.

Once again, these are all just approximations. However, they are a great indication of what you can anticipate paying. Fortunately, wheel bearings last a long time, so you won’t need to change them very frequently.

Shift back into park (for an automated transmission) or gear (for a manual transmission) prior to lowering the vehicle to the ground.

Spin the wheel/tire by hand and listen carefully. You should hear a soft rubbing sound which is just the brake pads gliding over the rotor. A grinding sound centered in the very middle of the wheel is a dead giveaway for a failing wheel bearing. It’s important to note that when wheel bearings first start to go, it will normally be difficult to hear and tell. Usually only a road test under the weight of the vehicle will reveal that the bearing is going out.

A targeted and careful selection of the bearing clearance is elementary, as the subsequent operating clearance has an effect on the service life (not the L10h service life), the temperature curve, the bearing performance as well as the running noise. The effects of the operating clearance on the service life are shown in the graph.

Honda Civic wheel bearingnoise

Materials and manufacturing Have you already had a look at our chapter on structure and function? Maybe you asked yourself what rolling bearings are actually

When calculating the reduction in operating clearance due to a temperature difference, you must take several factors into account.

Why is this done? The spring preload force causes all the balls to fit snugly against the raceways of the deep groove ball bearing (axial bearing clearance = 0µm). The preload thus causes a tension at the contact points of rolling elements and raceways. This reduces the operating noise and improves the vibration behaviour.

Rear wheel bearings today are usually no different than fronts in terms of a complete hub bearing or pressed-on units. In the vast majority of cases here, a complete unit is used and unbolted / bolted to the rear transaxle (2WD vehicles) or independent rear axle.

Back in the old days, wheel bearings were composed of 2 cone bearings on each front side. When removing the brake rotors (or drums) these more old-fashioned bearings could be serviced by packing the bearings with grease. While some vehicles still retain this style of bearing, it is rare.

With the wheel bearing replacement cost in mind, you may be wondering if you can drive with a bad wheel bearing. A bad wheel bearing needs to be changed as soon as possible. There is no lubrication on a bad wheel bearing. Consequently, as you drive with a bad wheel bearing, you run the risk of the wheel bearing completely failing and breaking apart, which can cause massive stability problems when driving, even a crash. If you’re in the middle of nowhere and you need to drive a short way to get help to prevent this scenario, you should drive at a slower speed so that your wheel remains intact for a couple more hours.

Damn, bearing damage! If you consider that rolling bearings are exposed to continuous pressure and shear stress, this is nothing unusual to begin with. What

Wheel bearings live a tough life. Most of a vehicle's weight rides on the wheel bearings at the 4 corners of your vehicle. Once these bearings begin to deteriorate, a humming noise becomes noticeable. It's easiest to hear at speed when you turn the wheel slightly from side to side. When a rear wheel bearing goes out, the humming or grinding noise is usually constant.

Today, aside from rear-wheel drive vehicles that use a solid axle (like trucks), most vehicles use a hub bearing. These consist of a bearing and flange surface that is bolted directly to the steering knuckle or rear transaxle. The bearing then has a hub face, with the wheel studs and tire-mounting surface. Often, an axle (often one with a CV joint) also passes through this bearing via a splined surface and has a large hub nut (called a spindle nut) that secures it at the bearing. This design makes up most bearings on vehicles today. There are some vehicles that still use a pressed-in hub bearing, where you re-use the original wheel hub, but this is becoming rare.

One possibility, which is often used in electric motors, for example, is axial preloading of the rolling bearings by means of a spring (preloading by means of a constant sprung preload force). This is shown symbolically in the illustration. The spring force acts around the entire circumference.

The internal mobility of the rolling elements and the rings in the axial and radial direction is referred to as bearing clearance Bearing clearance refers to an unmounted rolling bearing Operating clearance refers to a mounted rolling bearing in operation Typical bearing clearance classes (values for a deep groove ball bearing 6008): C2 (1->11µm) -> CN -> C3 -> C4 (28->46µm) Preload is defined as either a negative radial operating clearance or the axial preloading of a rolling bearing by means of a spring or a clamping system

The angular contact ball bearing is virtually the brother of the deep groove ball bearing. Characteristics of angular contact ball bearings Perhaps you already know

Characteristics of tapered roller bearings Here you see an NTN tapered roller bearing. As the name suggests, tapered roller bearings are roller bearings, whereby the

Bearing clearance and operating clearance, isn’t that the same thing? And preload, I’ve heard that before, but what is that supposed to be?! How do I calculate all these values and what criteria are important when choosing the right operating clearance? Perhaps you are confronted with such questions – you will find the answers and more detailed information in this article.

Interference fit, transition fit, clearance fit. You should know and be able to define these three types of fit after reading this article. But before

You can lower your wheel bearing replacement cost by changing them yourself. You should be able to do this in your own garage. However, it will require some specialized tools. Make sure to reference your vehicle’s service manual or seek out online information and determine the kind of wheel bearing your car or truck is geared up with prior to starting the repair work. Keep in mind that AutoZone rents all the specialized tools you will need to replace your wheel bearing and does so for free! Learn more about Loan-A-Tool here.

The shaft is then rotated at 8,000 rpm, for example. The bearing 6008C4 now has a temperature of 100°C on the inner ring and 90°C on the outer ring. But what is actually happening now? Well, the inner ring and the outer ring expand due to the heat, but the inner ring expands more than the outer ring due to the temperature difference. Because of this, the clearance in the bearing is reduced from +3 -> +44µm to -5.0 -> +36.5µm. This reduction of about 7.5µm is calculated with a computer programme or alternatively with the help of catalogue formulas.

If the table for the bearing clearance classes mentioned above is extended by a further column, the balls which “bear” the radial force (for example the weight of the shaft) are shown in the fourth column (load bearing).

The vast majority of vehicles today use a complete-unit hub bearing. Here, the cost of the bearing is usually the bulk of the expense, as most hub bearings run between $80.00 to $300.00. Many of these have ABS sensors built into them. These bearings are unbolted from the steering knuckle, and a new bearing bolted on. Expect to pay for 1-2 hours of labor to replace per side, usually between $80-200.00.

Wheel Bearing costAutoZone

The most practical way to explain internal clearance is to imagine a bearing (for example, a deep groove ball bearing) that you are holding in your hand. If you try to move the inner ring of this bearing up and down or to the left and right while holding the outer ring, you will notice a small displacement in the radial (black arrow) or axial direction (purple arrow). This displacement is called bearing clearance. Conversely, the inner ring can also be held and the outer ring moved up and down or to the left and right. This is also referred to as bearing clearance.

Formula 13 can be used to calculate the reduction in bearing clearance. For the sake of simplicity, factors such as the shape of the bearing, shaft and housing as well as the materials used are taken into account by a numerical value of 70%-90%. In general, the larger the interference, the more the bearing clearance is reduced.

Some force is needed to mount the 6008C4 on the shaft to overcome the interference. Due to this interference, the bearing clearance is reduced so that after mounting on the shaft it becomes +3µm -> +44µm. Now the shaft is mounted with the 6008C4 inside a steel housing. In this example, the housing has a H6 (0µm/+19µm) tolerance and the outer ring of the bearing has a tolerance of 0/-13µm.

The bearing clearance refers to an uninstalled rolling bearing and can be described as the internal mobility of the rolling elements and the rings in both axial and radial directions. The operating clearance can also be described as the internal mobility of the rolling elements and the rings in both directions, but it refers to an installed bearing in operation.

You will certainly not come across CN, C3 and C4 for the last time. The other bearing clearance classes are only used under special operating conditions.

Formula 12δeff = δo – ( δf + δt )δeff = Effective interference (due to fits), mmδo = Bearing clearance, mmδf = Decrease in bearing clearance due to interference caused by fits, mmδt = Decrease in bearing clearance due to temperature differences between inner and outer rings, mm

These vehicles up until very recently still used hub systems that house roller bearings or cone style. While these bearings themselves are often as cheap as 2WD vehicles, the process of removing them and disassembling the hub is often a little more time-intensive. Expect to pay for 1-1.5 hours of labor per side, which is usually $80-160.00, plus the bearings to replace. Keep in mind if the race is damaged in the hub, it will need to be pressed out, and a new race pressed in, leading to more time.

8613869596835

8613869596835