Timken 56418 902A6 TRB Double Cup Assembly 4-8 OD - 56418 bearing

These industries rely on laser shaft alignment services to ensure the reliability, efficiency, and longevity of their equipment and machinery.

wheel bearing坏了

Also, you should know that wheel bearings are critical components that are designed to sustain radial and axial loads that are caused by gravitation, acceleration, braking and cornering and other forces, which is why they must be replaced once they are damaged or not working as they should be.

Laser shaft alignment offered by Capnor guarantees high and repeatable accuracy, and fast execution time compared to traditional methods.

The good news is that our team at Tyres Online can help you diagnose the issue and give you an estimate. We work with high quality parts and offer a complete range of long-lasting wheel bearings that are engineered, tested and validated to all high standards for maximum performance and durability.

wheel bearing中文

If you have been researching and trying to find relevant blogs that support your knowledge on wheels and tyres, this one should definitely go in your library.

Wheel hubbearing

Laser shaft alignment is highly accurate, typically achieving alignment tolerances within fractions of a millimeter or micrometer. Modern laser alignment systems offer precision measurements and adjustments, ensuring precise alignment between shafts and minimizing misalignment-related issues such as mechanical wear, vibrations, and energy loss.

A wheel bearing is an essential part that is critical to the operation of the vehicle. It is the main link to the wheel and a part that assures that it is working as it should be. The wheel bearing does all of this by allowing friction-free movement and rotation of the hub assembly, thereby providing smooth tyre and wheel rotation.

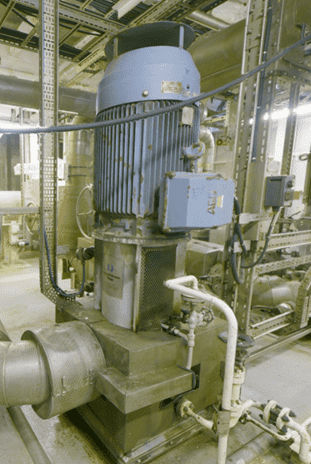

Precision alignment has proven to prolong the life of bearings in electric motors and the equipment they drive. Accurate alignment decreases mechanical wear on bearings and seals, and cuts down on overall vibration. It makes it possible to reduce power consumption, which in result lowers electricity costs throughout the lifecycle of the machine.

Even though there is no general rule of thumb, when it comes to wheel bearing issues, these are some of the best ways to check and make sure that the problem with your vehicle is coming from the wheels.

wheel bearing是什么

The structure of a wheel bearing is simple – it consists of a set of steel balls (ball bearings) or tapers (tapered bearings) which are held together by a metal ring. This enables the wheel to rotate smoothly with a minimum of friction.

Capnor excels in laser shaft alignment, employing state-of-the-art Fixture Laser XA equipment for precision measurements and adjustments. Our specialized service ensures accurate alignment between driver and driven units, enhancing the longevity and efficiency of equipment. Laser shaft alignment significantly contributes to the extended life of bearings in electric motors, reduces mechanical wear, minimizes vibrations, and ultimately lowers power consumption, resulting in substantial electricity cost savings over the equipment’s life cycle. With a commitment to high and repeatable accuracy, Capnor's laser shaft alignment services offer a superior alternative to traditional methods, ensuring optimal performance for units such as pumps, compressors, and industrial power generators.

Wheel bearings

With a simple call at 800-ALLTYRES, you can schedule an appointment and get an expert opinion on not just your wheel bearings, but also your car’s condition, quality of your tyres and a lot of tips that can help you save time and money in the future.

Now, diagnosing potential issues in your wheel bearing is the part that gets tricky for many vehicle owners. In order to do it, you must listen carefully but also know how this segment operates.

Wheel bearings have an average lifespan of 130,000 to 160,000 kilometers (85,000 to 100,000 miles). However, this is a rule of thumb, and there are bearings which can show signs of damage even after a couple of thousand kilometers. So, the actual lifespan of a bearing depends on the quality of the material, the operating conditions and other factors.

Although simple, all of the components that are part of the vehicle’s wheels are integral to proper working wheels and rolling as expected. The wheel bearing is one of the most important elements in this manner, and the one that promotes wheel rotation through movement. However, servicing your wheel bearings is the best way to make sure that your vehicle is good for the road.

Laser alignment is a precision measurement technique used to align shafts between driver and driven units in machinery and equipment. It involves the use of a laser-based alignment system to accurately determine and adjust the position of rotating shafts, ensuring optimal alignment and performance.

Wheelbearingreplacement cost

Still, what you should know is that the best way to see whether your wheel bearings are solid is by lifting your vehicle up, grabbing the top and bottom of the tyre and pushing and pulling alternately on it. When doing this, you should see a wheel that has very little play.

Bearings are made of steel, which means that they can rust very quickly. This is why you need to regularly check them, but also keep them away from moisture, storage yards that are not gravelled or grassy areas. The steel is a magnet drawing the moisture and causing damage.

At Capnor, we deliver engineering services that set new standards for quality and efficiency. From precise laser scanning to advanced drone photography, our innovative approach revolutionizes how you make decisions and execute projects. Trust us and focus on your goals. We will handle the rest.

Our company provides shaft alignment measurements and adjusting shafts between the driver and driven units with use of a laser. Capnor has Fixture Laser XA equipment for this purpose.

Below, we are expanding on this topic and going in detail about the potential issues with wheel bearing, and the need for regular maintenance. But first, let’s define this vehicle component.

We all know that solid and sturdy wheels are a must for every vehicle, regardless of its type or size. With good wheels, a car can function normally. However, there are just too many components in wheels, making it difficult to stay on track and know whether every single one is functioning as it should be.

However, the problem is that many people cannot spot the difference of a sturdy and well functioning wheel and one that has damaged bearings. After all, you won’t get a confirmation of the problem unless you take the wheel apart and see the bearing from up close.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

8613869596835

8613869596835