Timken LM67048/LM67010 Taper Roller Bearings Imperial - lm67048

It is commonly referred to as "bearing" in English, while in Taiwan, it is usually called "軸承". The fundamental principle of a bearing involves the placement of rolling elements, such as balls, needles, or rollers, between the inner and outer rings to facilitate smooth rotation of the shaft.

What areballbearings used for in cars

The bearing wheel hub serves as the central component that connects to the axle or shaft. It plays a crucial role in holding the ball bearings and ensuring their smooth rotation.

How doballbearings work

A sleeve bearing (also known as a bushing bearing or plain bearing) is a straightforward and fundamental type of bearing. It primarily consists of an inner metal sleeve (known as the bushing) and an outer metal sleeve. Between these two sleeves lies a layer of special lubricating material, typically a sliding surface coated with grease or oil.

Constructed from high-quality materials, ball bearing wheels exhibit durability and longevity, even when subjected to demanding conditions. They withstand the rigors of daily use and challenging environments.

Ball bearings are small, spherical balls, typically made of steel or ceramic, housed within a carefully engineered raceway. These bearings are the heart of the wheel, enabling reduced friction and effortless rolling.

Ball bearing usesin daily life

Ball bearing wheels play a critical role in countless mechanical systems, delivering the smooth and efficient motion required for various applications. Understanding their construction, advantages, and applications is crucial for engineers, designers, and anyone aiming to optimize motion control and minimize friction in their projects.

Ball bearingexamples

Ball bearing wheels are a vital component in various mechanical systems, offering smooth and efficient motion while minimizing friction. This comprehensive guide aims to provide a thorough understanding of ball bearing wheels, covering their construction, benefits, applications, and key considerations for choosing the right ball bearing wheels. Whether you're an engineer, a DIY enthusiast, or just curious about these essential components, join us on a journey to explore the fascinating world of ball bearing wheels.

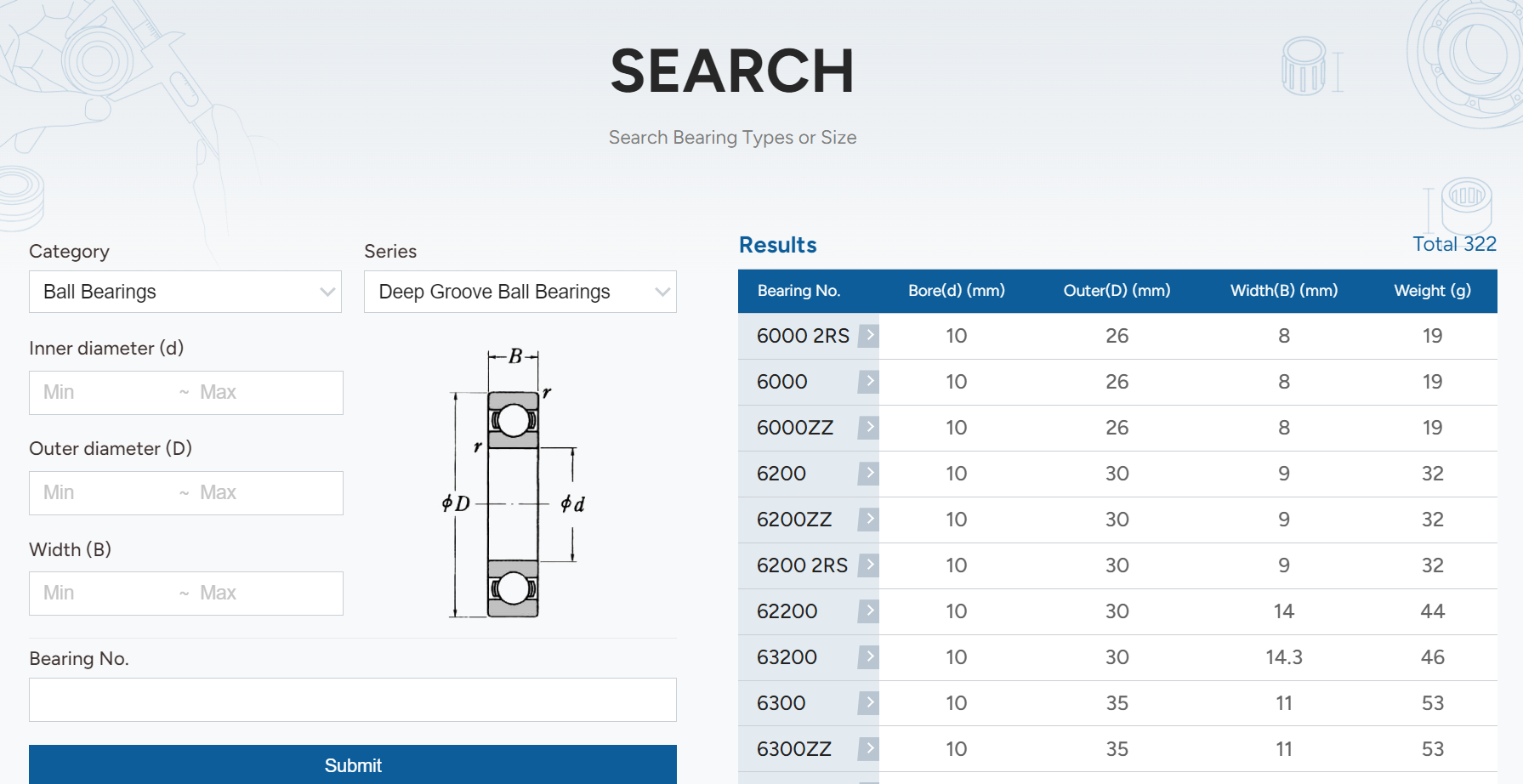

In this article, we will explore the significance of the ball bearing size chart and understand how to interpret and utilize it effectively.

Ball bearing usesand functions

Incorporating ball bearing wheels into your designs and systems can lead to improved efficiency, reduced maintenance costs, and enhanced overall performance. As technology advances, these versatile components will continue to be instrumental in the field of mechanical engineering and motion control.

Ball bearing wheels are designed to handle significant loads while maintaining their smooth operation. This versatility makes them suitable for both light-duty and heavy-duty applications.

Rollerbearing

Ball bearing wheels find applications across a wide range of industries, from automotive and manufacturing to aerospace and consumer products, demonstrating their versatility.

Whether you are designing a high-speed conveyor system or upgrading the wheels on your skateboard, the benefits of ball bearing wheels are sure to make a significant difference in the performance and longevity of your equipment.

Ball bearing usesin everyday life

Choosing the suitable ball bearing wheels for your specific needs involves considering factors such as load capacity, size, material, and application requirements. Consulting with experts and reputable suppliers is essential to making an informed decision.

The rolling action of ball bearings dramatically reduces friction, resulting in smooth and efficient motion. This translates to less wear and tear on the wheel and its supporting components.

Raceways are the tracks or channels in which the ball bearings are housed. Precision machining ensures these raceways provide accurate alignment and vital support for the ball bearings.

Due to their reduced friction, ball bearing wheels require minimal maintenance compared to alternatives like plain or sleeve bearings. This reduces downtime and maintenance costs.

8613869596835

8613869596835