Timken Set 401 | 580 Bearing and 572 Race | Drive Axle ... - bearing cross reference timken

Cylindrical roller bearings

In addition, they are very robust, thanks to which they are used in the most demanding industrial applications. Thrust spherical roller bearings are separable ...

Needle rollerbearing

The ultimate failure mode limiting bearing life is rolling-element fatigue of either a bearing race or a rolling element.

Because they can bear heavy loads, angular contact bearings are used for heavy machinery and agricultural equipment. These bearings help run pumps, electric motors, gearboxes, steel mills, windmills, conveyors, and other high-speed applications.

Figure 2: An angular contact bearing's key components: outer ring (A), inner ring (B), raceway (C), cage (D), and ball (E).

Angular contact bearings are designed to handle combined radial and axial loads. Radial loads are perpendicular to the shaft and axial loads are parallel to the shaft. Read our complete rolling bearing guide to learn more about load types.

An angular contact bearing has an inner and outer raceway and spherical rolling elements rolling between the raceways. As seen in Figure 2, the raceways tilt towards the axial direction, so the contact angle between the balls and the raceways is inclined. This allows angular contact bearings to handle axial and radial loads at the same time.

A 4-point contact ball bearing is similar to a single-row angular ball bearing. It consists of an outer race that is flanked on both sides. The inner race is also flanked on both sides with a split in the middle and steel balls circled by a cage. The flanks, or flanges, are symmetrical, unlike single and double angular contact bearings.

NSK Spherical Rollerbearingpdf

Angular contact bearings have inner and outer raceways that are slightly offset, resulting in the balls mounting at an angle, making them suitable for radial and axial loads. The angular contact ball bearing advantage is that the axial load-carrying capacity increases as the contact angle increases. This article covers the design and operation of these bearings, their different types, and their applications.

Nsk pdf

Static Load Capacity: 1,500 lb. Max. RPM: 20000 Operational Temp. Range: -40 Degrees to 212 Degrees F Bearing Race and Balls Material: 52100 Chrome Steel Cage ...

202452 — What Other Symptoms Indicate Bad Wheel Bearings? · Unusual noises coming from the wheels · Poor handling · Pulling to one side while driving or ...

Typical angular contact bearings are constructed to have a 15° to 25° contact angle between the raceway and rolling elements. The higher the contact angle, the higher the axial load the bearing can support.

Back to back vs face to facebearing

The sections above have primarily dealt with single-direction angular contact ball bearings. To summarize and add to that discussion:

Single-row and tandem ball bearings provide one-directional thrust for axial loads. The contact angle guides the direction, which also determines the gradient of the combined load.

We put together this bearing guide exploring the ones we stock. If you are looking for standard bearings at a lower price to get you rolling we carry a number ...

Super precision bearings

KRV MOTO 180() - - KYMCO MOTO ACCESSORIES .

Mityvac model MV6838 is the most complete vacuum brake bleeding and master cylinder refill kit available. It features our powerful MV6830 vacuum brake bleeder.

Thrust rollerbearing

The double-row angular contact ball bearing (Figure 4) is similar to two single-row bearings arranged back-to-back. In addition to radial and axial loads, they can absorb tilting moments. The advantages of double-row contact bearings include:

Oct 18, 2024 — - The removable and dishwasher proof parts allow easy cleaning. Warranty: 2 years. Long product name Princess 182020 ...

Angular contact bearings are chosen when both radial and axial loads need to be supported. Consider the following when selecting angular contact bearings:

Choose from our selection of tapered conveyor rollers for curves, tapered round-groove conveyor rollers, round-groove conveyor rollers, and more.

To remove excess play during bearing installation, users sustain a load pressure called preloading. Angular contact bearings require preload because they have to work in the pre-defined direction for axial loads.

Deep grooveball bearing

Angular contact bearings can only support axial loads in one direction. Therefore, it's common practice to use a pair of these bearings mounted next to each other with the raceways tilting in opposite directions. An alternative is to use a double-direction angular contact valve, which is essentially two bearings joined together.

The temperature range for a hot plate can vary significantly, from as low as 300°F to as high as 2500°F. The accuracy and uniformity of the temperature are ...

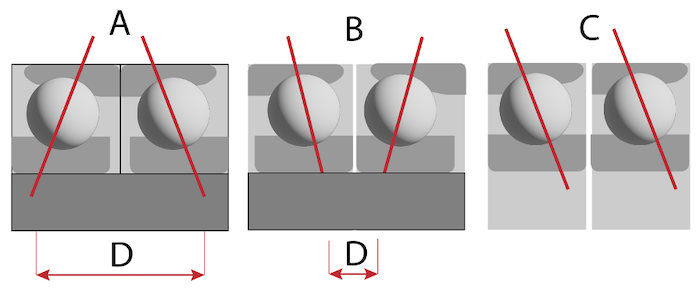

Figure 3: Single-row angular contact bearing mounting methods: back-to-back (A), face-to-face (B), tandem (C), and the distance between the bearing center and loading point (D).

The single-row bearing must be preloaded in the direction of the contact angle, as it can only handle axial loads in that direction. Two single-row bearings can be fitted in back-to-back, face-to-face, or tandem arrangements:

8613869596835

8613869596835