Timken Tapered Roller Bearing Assembly - 33117 - 33117

The load being applied on a bearing induces the elastic deformation to occur at the point where the rolling elements come in contact with the bearing rings. For this reason, the amount of displacement of the bearing increases along with the increase in the applied load.For angular contact ball bearings and tapered roller bearings, the relationship between the axial load (preload) and the amount of displacement in the axial direction (rigidity) is used to apply an axial load needed for the preloading (see Figure 7).

Bearing preloadcalculator by Timken

With angular contact ball bearings and tapered roller bearings, an axial load is applied for the preloading.In this situation, back-to-back arrangement is most often used (see Figure 6).This is because with back-to-back arrangement the load center position dimensions become larger and the amount of displacement in the bearing shaft center position decreases (the rigidity increases).

Applying preload to the bearing and decreasing the amount of displacement in the shaft center position in this manner is called increasing shaft rigidity.

Bearing preloadspring

As for high-precision matched pair angular contact ball bearings for use in machine tool spindles, JTEKT provides these ready-matched (see Figure 8).

It is important to set the amount of preload appropriately in consideration of factors such as the rotational speed and lubrication conditions.If you increase the amount of preload, the rigidity of the bearing will be raised, but it will have a significant impact on the bearing service life, the increase in temperature, and so on.

Bearing preloadformula

Applying preload causes the bearing's internal clearance to become slightly negative, causing a greater number of rolling elements to come in contact with the inner and outer rings.The difference of the elastic deformation among rolling elements contacting with the rings becomes smaller. As a result, the amount of displacement in the bearing shaft center position decreases (see Figure 3b).

Wheelbearing preload

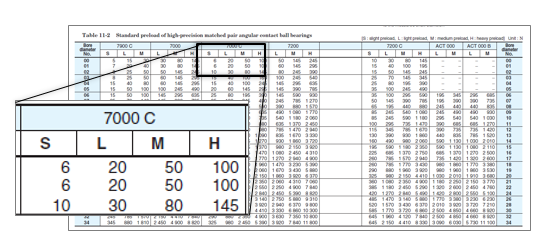

With these high-precision matched pair angular contact ball bearings, so that you can freely select the amount of preload best suited to your application, JTEKT endorses four types of standard preload: slight preload (S), light preload (L), medium preload (M), and heavy preload (H). (See Table 4.)

Generally, bearings are operated with a certain amount of proper clearance allowed. For some applications, however, bearings are mounted with axial load of such magnitude that the internal clearance will be slightly negative. This axial load is referred to as "preload".

Bearing preloadgauge

However, at the rolling elements located on the opposite side of the load direction, no load is applied and no elastic deformation occurs (see Figure 2).

The contact condition between the rolling elements and the bearing rings (or the races) differs depending on whether there is internal clearance in the bearing or preload is applied to the bearing. Allow us to explain the contact condition using radial bearings as an example.

(*1) Machine tool spindles and angular contact ball bearings for high-speed rotation: The Applications of Bearings II: This is how bearings are used for machines in industry

Because of this difference in elastic deformation due to the position of the rolling elements, the position of the shaft center (i.e. bearing center) changes slightly (see Figure 3a).If the direction of the load changes, the shaft center moves in other direction, causing vibration.

How to Select the Right Bearing (Part 1): The order of priority for selecting bearings, and the types of bearings How to Select the Right Bearing (Part 2): How to decide the bearing arrangement How to Select the Right Bearing (Part 3): Bearing dimensions and service life How to Select the Right Bearing (Part 4): Bearing limiting speed, running accuracy, and fits

Bearing preloadSKF

Furthermore, with roller bearings, the amount of elastic deformation caused by the load is smaller than with ball bearings.

Bearing preloadtool

See the following for a detailed explanation: Preload and rigidity - Ball & Roller Bearings Catalog Rigidity and preload of bearings - Precision Ball & Roller Bearings for Machine Tools

The Applications of Bearings II: This is how bearings are used for machines in industry The Applications of Bearings I: This is how bearings are used in cars

In Part 5, we will explain about bearing preload and rigidity as measures for whether the bearing type you chose was appropriate.

If you post a question after sending a gift to someone, your question will be displayed in a special section on that person’s feed.

Bearing preloadcalculator

If there is internal clearance in the bearing, the largest load will be placed on the rolling elements located nearest the direction of the load. This load induces a slight elastic deformation at the point where the rolling elements come in contact with the bearing rings. When the load is removed, it returns to normal and the elastic deformation disappears (see Figure 1).

The Language Level symbol shows a user's proficiency in the languages they're interested in. Setting your Language Level helps other users provide you with answers that aren't too complex or too simple.

8613869596835

8613869596835