Timken ® Thrust Bearings - what is a thrust bearing

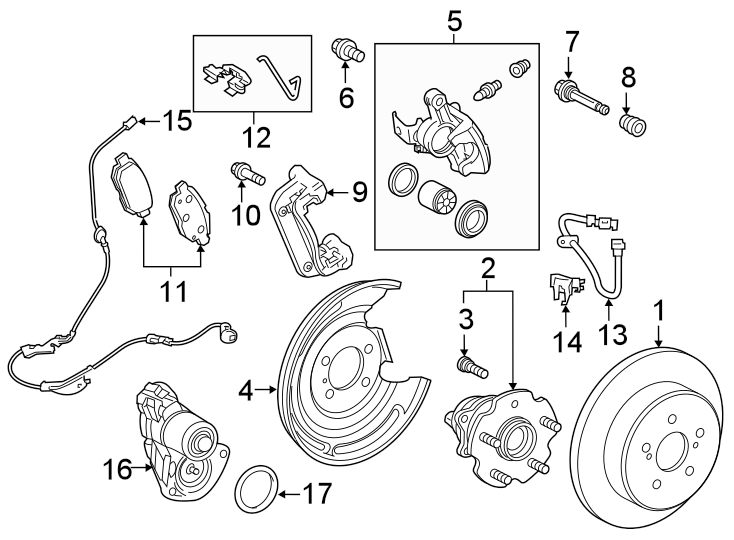

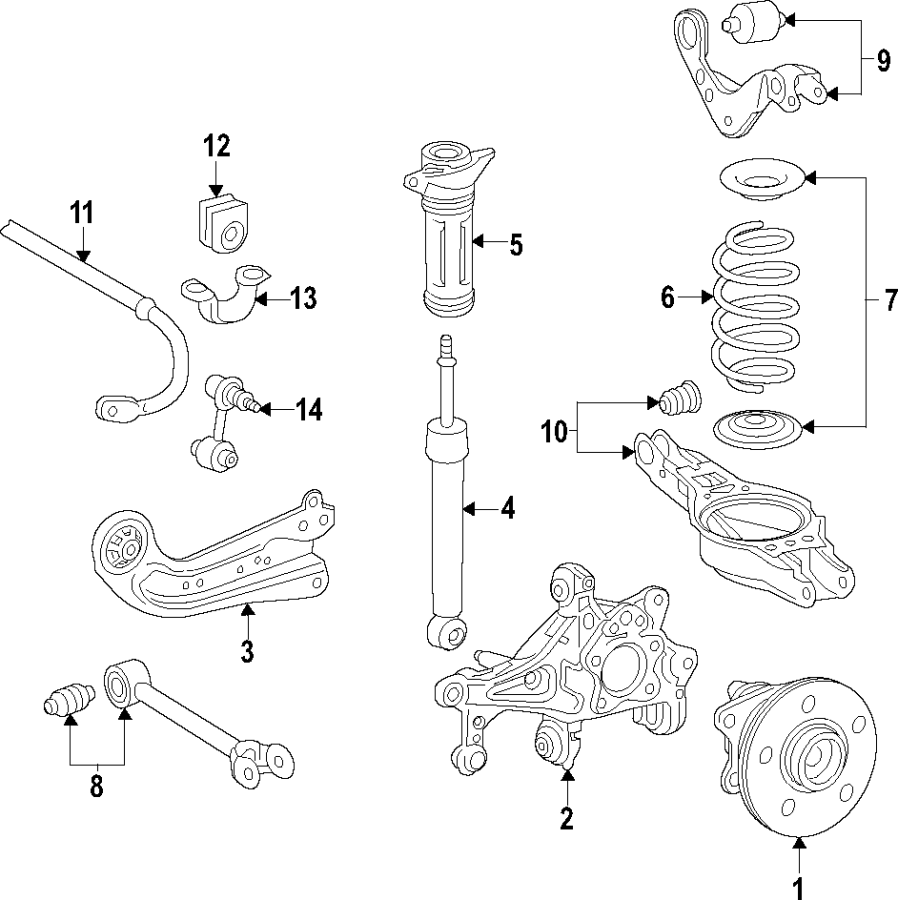

Hub. Bearing. Exc.Japan Built. Wheel Bearing and Hub Assembly. AND. ABS sensor. AND. AND Assembly, A. Wheel Bearing and Hub Assembly

Fits Corolla (2020 - 2024)2023-24 W/O LE, US built. Corolla; US Built. Corolla; US Built; FWD. SEDAN, 2023-24 W/O LE, US built. Wheel Hub And Bearing Assembly - Repair or ReplaceA wheel hub may need to be replaced if the wheel bearing in your Toyota Corolla is being serviced, or if your ABS or traction control light is on.

Fluke tools

ACCUSHIM, INC. has one of the largest inventories of pre-cut shims in the Nation. We manufacture and distribute the ACCUSHIM line of pre-cut slotted stainless steel shims used for shaft alignment in seven sizes and fifteen thicknesses as well as custom shims to suit your needs.

Easy-Laser XT440

Product Features Reduces vibration levelsExtends bearing and seal lifeLess unscheduled downtimeLonger MTBF SPECIFICATIONS of the SHAFT HOG with Standard Fixtures... Shaft Diameters: 1/8" --- 20"Rod Height above coupling/shaft: 6.5" (Can be decreased to 5" with optional VRF-5 short rod or increased to 12" with optional VRF-12 long rod. For increased height, all the rods connect to one another for unlimited height)Width of Mounting Brackets: 7/8" (Can be decreased to 1/2" by using the optional Thin Magnetic Fixtures). Report: Click here to view Laser Alignment Report Components: Click here to view Shaft Hog Components This item is currently not available - Call Accushim for updated status The ergonomically designed control unit fits comfortably in one hand. The live display means that you will get instant feedback when shimming or moving the machines. This eliminates the guesswork and back and forth you're suffering through now. All this at an affordable price that means a really quick payback. Accurate and Reliable The Shaft Hog features a unique "laser line" instead of the traditional laser dot. This makes setup and alignment much easier, as the line is wide and is easily projected to the laser detector. The Shaft Hog also features graduated labels on the laser heads, that work with the laser lines, to help the operator "visualize" the misalignment condition. This visual cue reinforces the digital values that are displayed on the unit, and makes evaluation and correction of misalignment an easier process. The alignment data is continuously updated. All movements of the motor are simultaneously displayed on the screen. The measurement results are displayed with a resolution of 0.0001". As you shim or move the machine the values update to let you know exactly where you are each step of the way. This means no more guessing about the shim amount, or how much to move a machine. With the Shaft Hog laser alignment system there is no interpreting of the values as with dial indicators. The position sensitive detectors precisely measure the misalignment. The large LCD display clearly presents the position of the machinery being aligned. The Complete Laser Alignment Tool The Shaft Hog comes with all the hardware and tools you need to begin doing laser alignments as soon as you open the carrying case. Sleek anodized aluminum chain brackets fit a wide range of shaft diameters (from approximately 1/8", and extra chain lengths can be added to accommodate virtually any shaft diameter). The transmitter-detector units are mounted on rods extending from each of the brackets. The transmitter-detector units are clearly labeled (one for the stationary machine, and the other for the movable machine). The cables and the display unit are also clearly marked, simplifying the set up. Once the transmitter-detector units are mounted they plug directly into the display box. The easy-to-use, ergonomically designed display fits right in your hand. Its intuitive design means you can step through an alignment as soon as you pick it up. The Shaft Hog has been designed to let you concentrate your skill and effort on performing precision alignments, not on figuring out how to use the tool. The Shaft Hog is powered with standard batteries (2 "C" cells). Approximately 24 hours of continuous operation are obtained from a fresh set of batteries. The system is delivered in a rugged case and includes all the equipment required for horizontal shaft alignments. Technical Data Measuring units Housing material ABS plastic Type of laser Diode laser Laser wave length 670 - 675 nm Laser class 2 Maximum laser power 1 mW Maximum distance between measuring units 2.8 ft (850 mm) Type of detectors Single-axis PSD Cable length 5.2 ft (1.6 m) Dimensions 3.4 x 3.1 x 1.5 in (87 x 79 x 39 mm) Display unit Housing material ABS plastic Display type LCD 1.4 x 1.9 in (35 x 48 mm) Battery type 2 x 1.5V "C" Alkaline (LR14) Operating time 20 hours continuous operation Auto power off After 1 hour if no keys are pressed Displayed resolution 0.1 mil (0.0001"); (0.01 mm in metric mode) Dimensions 9.1 x 3.2 x 2.4 in (230 x 81 x 62 mm) Complete System Shaft diameter range with chain 20" maximum Accuracy of system <2% +/-0.00039 in Temperature range 32 - 140°F (0 - 60°C) Operating humidity Non-condensing Packaged Dimensions 20"L x 17"W x 10"H

This item is currently not available - Call Accushim for updated status The ergonomically designed control unit fits comfortably in one hand. The live display means that you will get instant feedback when shimming or moving the machines. This eliminates the guesswork and back and forth you're suffering through now. All this at an affordable price that means a really quick payback. Accurate and Reliable The Shaft Hog features a unique "laser line" instead of the traditional laser dot. This makes setup and alignment much easier, as the line is wide and is easily projected to the laser detector. The Shaft Hog also features graduated labels on the laser heads, that work with the laser lines, to help the operator "visualize" the misalignment condition. This visual cue reinforces the digital values that are displayed on the unit, and makes evaluation and correction of misalignment an easier process. The alignment data is continuously updated. All movements of the motor are simultaneously displayed on the screen. The measurement results are displayed with a resolution of 0.0001". As you shim or move the machine the values update to let you know exactly where you are each step of the way. This means no more guessing about the shim amount, or how much to move a machine. With the Shaft Hog laser alignment system there is no interpreting of the values as with dial indicators. The position sensitive detectors precisely measure the misalignment. The large LCD display clearly presents the position of the machinery being aligned. The Complete Laser Alignment Tool The Shaft Hog comes with all the hardware and tools you need to begin doing laser alignments as soon as you open the carrying case. Sleek anodized aluminum chain brackets fit a wide range of shaft diameters (from approximately 1/8", and extra chain lengths can be added to accommodate virtually any shaft diameter). The transmitter-detector units are mounted on rods extending from each of the brackets. The transmitter-detector units are clearly labeled (one for the stationary machine, and the other for the movable machine). The cables and the display unit are also clearly marked, simplifying the set up. Once the transmitter-detector units are mounted they plug directly into the display box. The easy-to-use, ergonomically designed display fits right in your hand. Its intuitive design means you can step through an alignment as soon as you pick it up. The Shaft Hog has been designed to let you concentrate your skill and effort on performing precision alignments, not on figuring out how to use the tool. The Shaft Hog is powered with standard batteries (2 "C" cells). Approximately 24 hours of continuous operation are obtained from a fresh set of batteries. The system is delivered in a rugged case and includes all the equipment required for horizontal shaft alignments. Technical Data Measuring units Housing material ABS plastic Type of laser Diode laser Laser wave length 670 - 675 nm Laser class 2 Maximum laser power 1 mW Maximum distance between measuring units 2.8 ft (850 mm) Type of detectors Single-axis PSD Cable length 5.2 ft (1.6 m) Dimensions 3.4 x 3.1 x 1.5 in (87 x 79 x 39 mm) Display unit Housing material ABS plastic Display type LCD 1.4 x 1.9 in (35 x 48 mm) Battery type 2 x 1.5V "C" Alkaline (LR14) Operating time 20 hours continuous operation Auto power off After 1 hour if no keys are pressed Displayed resolution 0.1 mil (0.0001"); (0.01 mm in metric mode) Dimensions 9.1 x 3.2 x 2.4 in (230 x 81 x 62 mm) Complete System Shaft diameter range with chain 20" maximum Accuracy of system <2% +/-0.00039 in Temperature range 32 - 140°F (0 - 60°C) Operating humidity Non-condensing Packaged Dimensions 20"L x 17"W x 10"H

Your cart will be set to In-Store Pickup By adding this item to your cart, the shipping option will not be available for your order. The In-Store Pickup option will now be defaulted at checkout.

8613869596835

8613869596835