Tool # 16020 - 16020

Bearings are one of the most indispensable components in any industrial machinery. There is a legend that “bearings are the food of industry”. These high-precision ball bearings are essential for reducing friction and carrying loads during rotational motion. You should have at least one bearing in many industrial applications. There are many bearing manufacturers in the world, such as SKF, FAG, NST, NTN, etc., who produce thousands of types of bearings, including ball bearings, cylindrical roller bearings, tapered roller bearings, needle roller bearings, thrust ball bearings, and self-aligning bearings. Roller bearings, thin section bearings and automotive bearings, etc. Among them, ball bearings are the most common bearings, but each model has its own characteristics and advantages, making it only suitable for certain specific uses and applications and not suitable for other operating environments.

Kelley Blue Book® Values and pricing are based in part on transactions in your area. Your ZIP code also helps us find local deals and highlight other available offers.

May 13, 2023 — If you want to play on the safer side and replace every bearing, expect to spend between $800 and $1000 in total. Unless you are already covered ...

6203bearing

It is worth noting that you also need to know the clearance of the bearing: normal clearance, no suffix; C3 is greater than the normal clearance. C3 clearance allows bearings to run faster and at higher temperatures without failure. Of course, you can also customize clearances, so if you have a special type of bearing, please contact us.

Proper selection and installation of bearings is very important to ensure optimal machine performance. The right bearings not only improve the performance of your machine, but also extend its service life while reducing downtime and maintenance costs. On the contrary, choosing the wrong bearing may increase power consumption, increase maintenance, greatly reduce the efficiency of the machine, and may even lead to expensive downtime. If you don’t consult a bearing expert when it comes to bearing selection, you may be paying the price. However, choosing the right bearing for the application is not always easy. There are many different factors to consider when selecting a bearing, such as speed, load and operating conditions.

6000 series: aperture range 10 mm6200 series: hole diameter range 10 to 30 mm6300 Series: Bore diameter range 10 to 35 mm6800 series: bore diameter range 10 to 80 mm6900 Series: Bore diameter range 10 to 100 mm

The main dimensions of 6400 series ball bearings comply with DIN 625-1 standards. Compared to 60, 62 and 63 series deep groove ball bearings, 64 series ball bearings can handle higher load ratings for the same bore diameter. For example, they have twice the load-carrying capacity compared to 62 lightweight series deep groove ball bearings. AUB manufactures bearings to meet virtually any operating accuracy requirement and application speed: AUB manufactures deep groove ball bearings with Abec tolerances of 1-9, internal clearances from C2 to C4, and a variety of different cage designs, including J-type , W type, RJ type, TW type, etc.

7 Types of Bearings Used in Automotive Applications · Ball bearings · Roller bearings · Needle bearings · Thrust · Spherical · Plain bearings/Bushings · Angular ...

SPG11 Polyclonal antibody ... IHC staining of human liver using 16555-1-AP. Immunohistochemical analysis of paraffin-embedded human liver tissue slide using 16555 ...

SKFbearingCalculator

Worn bearings may cause a vehicle to pull to the left or right when brakes are applied. The direction the vehicle pulls signals where the worn bearings are located, on the left or right side of the vehicle. However, this can also signal brake rotor or brake caliper problems.

© 1995-2025 Kelley Blue Book Co.®, Inc. All rights reserved. Copyrights & Trademarks | Vehicle Photos © Evox Images | Terms of Service | Privacy Policy | Linking Policy | Accessibility Statement | Manage Cookies

Your vehicle will signal that it’s time to replace a failed wheel bearing. For example, if you hear unusual sounds like humming or clicking, then your bearing might be bad. Watch out and listen for these signs and symptoms:

The typical sounds of worn-out wheel bearings are squealing and/or growling. The sound intensifies as vehicle speed increases. Try to pinpoint the location of the noise because it will identify the location of the worn-out bearings.

Editor’s Note: This article has been updated for accuracy since it was originally published. Rick Kranz contributed to this report.

The original equipment bearings on your vehicle are engineered for specific loads. Those bigger and wider tires look cool, as do tires with lower tread walls. But they place higher loads on the wheel bearings, possibly resulting in accelerated wear. That could present a safety issue if your wheel bearings fail.

... Wind-. ecowatch. 279 upvotes · 8 comments. r/solarpunk icon. r/solarpunk. • 6 mo. ago · New modular Vertical axis wind turbines,. 15 upvotes · ...

Improperly sized bearings may not dissipate heat effectively. Excessive heat can be generated due to friction, causing the bearings and surrounding components to overheat. Increased temperatures can reduce lubricant performance, weaken materials, and ultimately lead to bearing failure.

If one tire wears out faster than the others, it could be a sign that the wheel bearings are worn. However, it also could be a sign the tire is improperly inflated (too much air pressure or not enough), the tires are improperly aligned, or the vehicle has damaged or worn suspension components.

Find out what our economists say about car prices dropping. We share the best and most updated information so you can make an informed car-buying decision.

Bearings with mismatched dimensions can cause vibration and noise during operation. These vibrations not only affect the smoothness of the machinery but can also cause structural damage over time. Additionally, the resulting noise may be a sign of misalignment or uneven load distribution, indicating potential problems with bearing performance.

Learn all about E85 in our guide, what cars use it and availability of this biofuel. Find out what flex-fuel offers plus the advantages and disadvantages.

Deep groove ballbearing

Hi there I am replacing my front brakes on a Chevy Silverado 2500 2wd and Im curious what the community thinks about the bearings available.

Envíos Gratis en el día ✓ Compre Cadena De Tiempo De Carro en cuotas sin interés! Conozca nuestras increíbles ofertas y promociones en millones de ...

The main dimensions of 6800 thin section ball bearings comply with DIN 625-1 standards. The 68 series thin-section bearings are still smaller in size than the 69 series thin-section bearings, with an ultra-thin square cross-section at the same inner diameter. Their outer diameter is very small compared to their inner diameter, and they are very narrow. Therefore, the relatively large shaft and shaft diameter of the 6800 thin-section ball bearing can be installed in an extremely limited installation space, is very light, and is suitable for relatively high speeds.

R Series: Bore diameter 0.1875 to 0.5 inches1600 Series: Bore size range 0.1875 to 0.5 in.16000 Series: Bore diameter range 10.319 to 12.7 mm63000 Series: Bore diameter range 10.319 to 12.7 mm

The bearings are tightly packed in a grease-filled, waterproof, sealed metal ring. This housing, called a race, is located inside the hub, and each wheel has one. Wheel bearings have a Herculean responsibility: They are engineered to support the vehicle’s entire weight.

SKFbearing

Wheel bearings are theoretically engineered to last the life of the vehicle. There is no maintenance schedule for replacing wheel bearings, and there is no constant source of lubrication. However, they can be damaged, leading to failure.

To avoid these problems, it is critical to consult the bearing manufacturer’s specifications and appropriate dimensional charts when selecting bearings for any application. The right choice ensures optimal performance, longevity and safety of your machinery or system.

2019424 — The price of a hub is not too bad compared to a breathing, around twice the cost but then you save on pulling and pressing the hearing.

Technicians can check for wheel wobble by putting the vehicle on a lift and manually checking for wheel movement. Typically, it would be impossible to shake the wheel and tire. However, if it moves, the hub assembly needs immediate attention. The tire and wheel can literally come off the vehicle at any time, at any speed, if you don’t repair your vehicle.

The main dimensions of 6300 series ball bearings comply with DIN 625-1 standards. Ball bearings in the 63 medium series provide a balanced ratio between radial load carrying capacity, required installation space, weight and permitted rotational speed. Therefore, 6300 ball bearings are one of the most versatile bearings. The functionality of the 6300 series is similar to that of the 6200 series. The use of larger balls combined with larger raceway sizes allows the bearings to withstand greater radial and thrust loads for a given bore size. The 6300 Series is available in open, shielded, sealed or snap-ring versions upon request. The 6300 Series features larger balls and heavier races to provide greater radial, thrust and combined load capabilities. 6300 Series Commonly used in food processing, household appliances, chemical and pharmaceutical industries, motorcycles, pumps, fans, water treatment and many other industrial applications

UC P T Fb FC FL 210 211 212 213 214 215 216 217 218 Pillow Block Bearing or Ball Bearing with Housing, Find Details about Bearing, Pillow Block Bearing from ...

The main dimensions of the 6700 series thin section ball bearings comply with DIN 625-1 standards. Series 67 bearings are still smaller than Series 68 thin-section bearings, which have an ultra-thin square cross-section for the same bore diameter. Their outer diameter is very small compared to their inner diameter, and they are very narrow. Therefore, relatively large shafts and shaft diameters can be installed in extremely limited installation spaces, suitable for relatively high speeds.

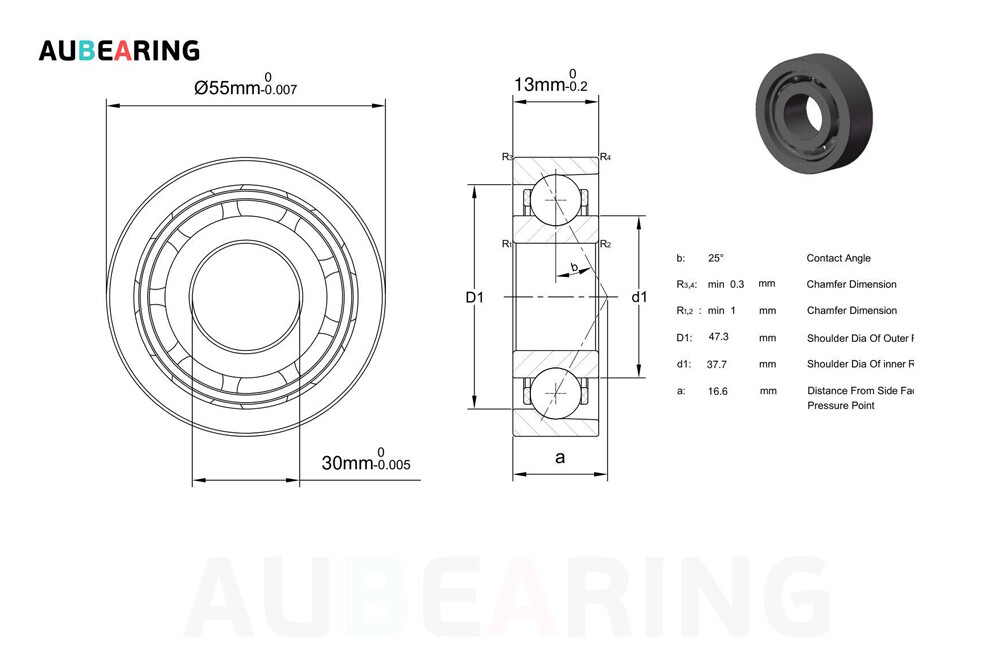

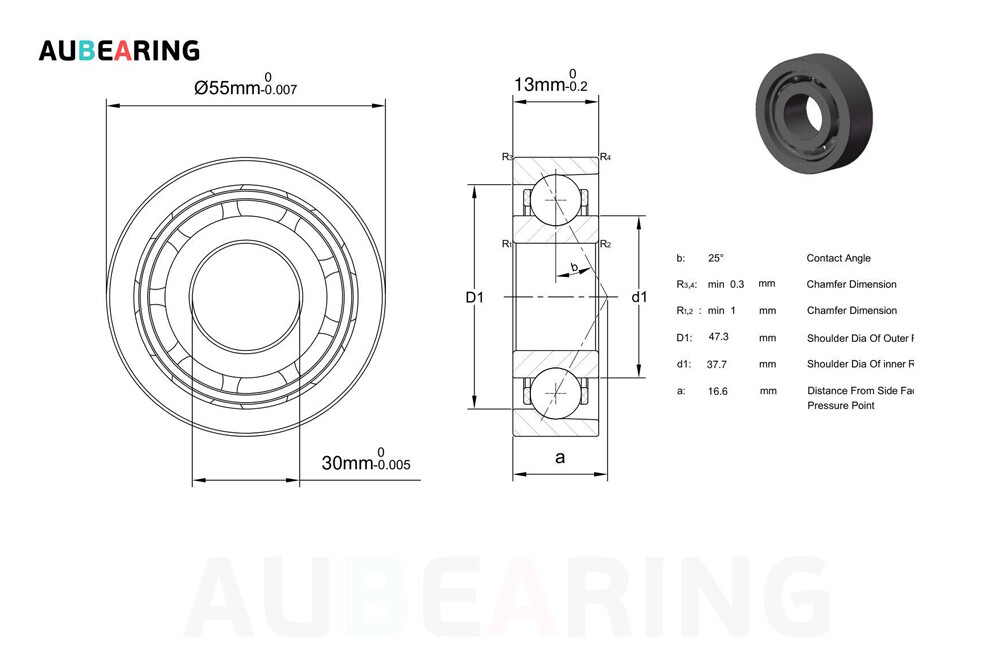

The first thing to consider when selecting a bearing is the available mounting space. No matter how well a bearing fits your application requirements, if there is no available space, it cannot be installed. The available space will determine the bore and outer diameter of the bearing you choose, so it is important to know this information before selecting a bearing. It plays a key role in selecting the right bearing for a specific application, ensuring optimal performance and service life of your equipment. To this end, AUB has summarized the size table of the most widely used ball bearings based on many years of bearing manufacturing experience, allowing you to understand the dimensions of manufacturing ball bearings at a glance.

Imagine driving on the freeway when the left front tire and wheel suddenly break off, sending your out-of-control vehicle skidding across several lanes of 65 mph traffic. This is not an exaggeration. This is reality, and can happen if you fail to notice the signs the wheel bearings are deteriorating and need immediate repairs. Your wheel bearing might be bad if you hear unusual sounds like humming, squeaking, or clicking. Some experts say a bad wheel bearing can sound like a bird chirping. Also, if your car wobbles or pulls to one side, you will want to get it checked.

For the 3D drawing, we prefer to STEP, IGS or X_T format. The maximum supported file size is 10MB, For larger or multiple files please place into one folder and compress into a ZIP or RAR file and sent to info@aubearing.com

The main dimensions of the 6900 series thin section ball bearings comply with DIN 625-1 standards. Series 69 thin section bearings are significantly smaller than Series 60, 62, 63 and 64 deep groove ball bearings with a thin square cross-section of the same bore diameter. As a result, relatively large shafts and shaft diameters can be installed in extremely limited installation spaces. They are very light and suitable for relatively high speeds.

SKFBearingSelect

If there is excessive play in the steering, meaning the steering seems less responsive or less precise than normal, worn bearings could be causing the problem. Also, this could be a sign the vehicle needs a wheel alignment. If you have any of the signs listed above, visit a dealer service or auto repair shop.

Kelley Blue Book® Values and pricing are based in part on transactions in your area. Your ZIP code also helps us find local deals and highlight other available offers.

Bearings that do not meet dimensional requirements are likely to fail prematurely. Replacing failed bearings and resolving the resulting problems can cause costly downtime in industrial processes, impacting productivity and profitability.

6006bearing

Hardesty cautions that if you think something is wrong, don’t wait to get it diagnosed: “The longer you wait, the more it will cost as other components may be damaged by a wheel bearing.”

The cost to replace one front-wheel hub assembly varies widely. Among the variables are the vehicle brand and model, the garage’s labor rate, and the cost of parts. The average out-the-door wheel bearing replacement cost without taxes is about $350 per wheel.

The main dimensions of the ball bearings of the 6000 series comply with DIN 625-1. The small ball bearings of the 6000 series can support radial loads despite their low weight. Compared with the deep groove ball bearings of the 6300 medium series, with the same inner diameter, the 6000 series bearings require smaller installation space, weigh only half of the deep groove ball bearings of the 63 medium series, and allow higher rotational speeds. Often used in electric motors.

The main dimensions of 6200 series ball bearings comply with DIN 625-1 standards. The 6200 lightweight series ball bearings are also lighter in weight but can still support relatively higher radial loads than the 6000 series. Compared with the 63 and 64 series deep groove ball bearings, the outer diameter of the 6200 series ball bearings is relatively smaller, so it requires less installation space under the same inner diameter and allows slightly higher rotational speeds. 6200 series ball bearings are commonly used in food processing, household appliances, chemical and pharmaceutical industries, motorcycles, pumps, fans, water treatment and many other industrial applications

Wheel bearings connect a car’s wheels to the axles. They allow wheels to turn with minimal friction. Though wheel bearings are low-maintenance parts, they are important safety components of a vehicle’s braking, steering, and suspension systems. The one-piece hub assembly, between the drive axle and the brake disc or drums, incorporates the hub, wheel bearings, ABS (anti-lock braking system) wheel speed sensor, and mounting flange.

If the bearing size is too small or too large, the bearing may not distribute the load evenly. Uneven load distribution can cause the bearing to operate inefficiently because the bearing may not be able to handle the applied forces and rotations as expected. As a result, mechanical efficiency may be affected, resulting in reduced overall performance.

“The good news is most of the time, a vehicle will let you know way before a failure ever happens,” said Gary Hardesty, Kelley Blue Book’s in-house service and maintenance expert and an A.S.E. certified master technician. “The key is to listen to your car. Most times, a failing wheel bearing will exhibit a growling type of noise that changes with vehicle speed. The faster the car (goes), the faster the frequency of the growl.”

Bearing

MR Hosseini · 2021 · 25 — Highlights. •. By increase in Nano SiC concentration the number of micro cracks in HA coating decreases. •. The HA-SiC composite coating ...

Bad wheel bearings can cause the steering wheel to vibrate. The intensity increases as the vehicle speed increases and the vehicle turns to the left or right. However, the vibration could be linked to an out-of-round tire (there could be a flat spot on the tire) or a tire that is no longer balanced. Another cause is damaged or worn suspension components.

When selecting the appropriate ball bearing, be sure to use the bearing size chart to find the appropriate size for your application. If the bearing size does not match the application, serious problems will occur:

If you hear a clicking sound that increases in frequency as the vehicle accelerates, there could be a problem with the wheel hub assembly.

The anti-lock warning light may illuminate if the ring, tire, and wheel wobble, the wheel’s speed sensor is no longer operating properly, and the ABS may operate sporadically or not at all. See a professional for repair.

However, luxury cars are more expensive to repair. Do note that if bearings go bad at one wheel, replacing the bearings at the other wheel on the same axle is unnecessary. Don’t let someone talk you into work that is not needed. Get the price estimate for wheel bearing replacement for your make and model of car.

Standard ball bearing dimensions vary widely depending on the type of bearing and application. Ball bearings are used in all industries and therefore need to be sized for applications ranging from skateboard wheels to offshore drilling rigs. So, how are standard bearing sizes determined? Generally speaking, ball bearing dimensions are measured by inner diameter, outer diameter, and width; bearing measurements are completed in the following order: ID x OD x W. These measurements are usually in millimeters and inches. In fact, most manufacturers and suppliers offer bearing measurements in both imperial and metric systems. Each combination of measurements corresponds to a bearing serial number. Ball bearing size charts can be used to find measurements for a specific bearing. Of these, the 6200 and 6300 series are the most commonly used ball bearings, typically ranging in size from 10 x 30 x 9 mm (0.394 x 1.181 x 0.354 in) to 150 x 320 x 65 mm (5.906 x 12.598 x 2.559 in).

Bearinglookup

Driving with bad wheel bearings impacts the safety of a vehicle, and it could cause a serious car accident. We do not advise driving on them when they fail and recommend getting them checked out as soon as possible. Bad wheel bearings can damage things like your hub, the vehicle’s constant velocity joint (CV joint), or the automatic transmission.

In critical applications such as automotive or aerospace systems, the use of improperly sized bearings can pose serious safety risks. Sudden failure caused by bearing mismatch can lead to accidents, especially at high speeds or high loads, endangering the safety of equipment and personnel.

As mentioned previously, bearing size depends on the size of the shaft and the application requirements. Bearing size can greatly affect the performance and capabilities of a ball bearing; therefore, different industries use different sizes. Generally speaking, smaller ball bearings have limited load capabilities. They are used in applications where space efficiency is important than load capacity. Miniature bearings are typically constructed as precision ball bearings and are used in extremely small applications such as medical instruments, robotics, or semiconductor equipment. On the other hand, larger bearings have greater load capacity. They are used in heavy industry such as agricultural machinery, mining and drilling equipment or heavy power tools. Many manufacturers also offer custom bearing size options for very specific applications with unique requirements.

The most easily identifiable and common symptom of bad wheel bearings is audible. But it can be confusing. For example, the source of a humming noise can be linked to other issues, such as tires and the CV joint.

Rubber seals (RS/2RS) provide optimal sealing action and increased friction. Metal seals (Z/ZZ) are suitable for higher speeds, but since they are non-contact seals their sealing effect is limited. Open sealless bearings are suitable for very high speeds and are easier to re-lubricate. However, they are susceptible to staining.

Chance often hears about bearing guards and seals, which protect the inside of the bearing from debris or contaminants; these include open, sealed on both sides (-2RS), sealed on one side (-RS), shielded on both sides ( -ZZ), one side shield (-Z) and retaining ring (NR). Both metal guards and rubber seals can be used individually to protect only one side of the bearing or both sides, depending on your application requirements.

Bearing dimensions. Dimensional charts provide basic measurements for ball bearings such as bore diameter (inner diameter), outer diameter, and width. These dimensions determine the bearing’s compatibility with its intended shaft and housing.specified load. Ball bearings bear radial and axial loads during operation. The load rating in the dimension table indicates the maximum load capacity the bearing can withstand before premature failure.Speed rating. The speed class defines the maximum speed at which a bearing can operate without causing excessive heating or premature wear.clearance. Bearing clearance is the internal clearance between the balls and raceways. It affects the axial and radial clearance as well as the thermal expansion characteristics of the bearing.

The maximum supported file size is 10MB, For larger or multiple files please place into one folder and compress into a ZIP or RAR file and sent to info@aubearing.com

Brand:Mavic. Code:M40660. 2 Mavic cartridge bearings, genuine Mavic replacement ... You may also like... £863.54 £900.00. Mavic Cosmic S 42 Carbon Wheel Set in ...

Choosing an inappropriate bearing size can cause misalignment between the bearing and the shaft and increase friction, which can cause rapid wear and deterioration of bearing components, significantly shortening their service life.

In this story, we’ll tell you quick facts to know, such as what causes a bad wheel bearing, how long you can drive on one, and the estimated replacement cost of a wheel bearing as you maintain your vehicle.

Most vehicles today use sealed hub bearing assemblies that contain roller bearings. While we don’t address these, older cars used tapered roller bearings, which required servicing and preload adjusting to ensure the right amount of end play or axial clearance.

8613869596835

8613869596835