TPSS Optional Resources For Home Learning for - Pre-K - tpss

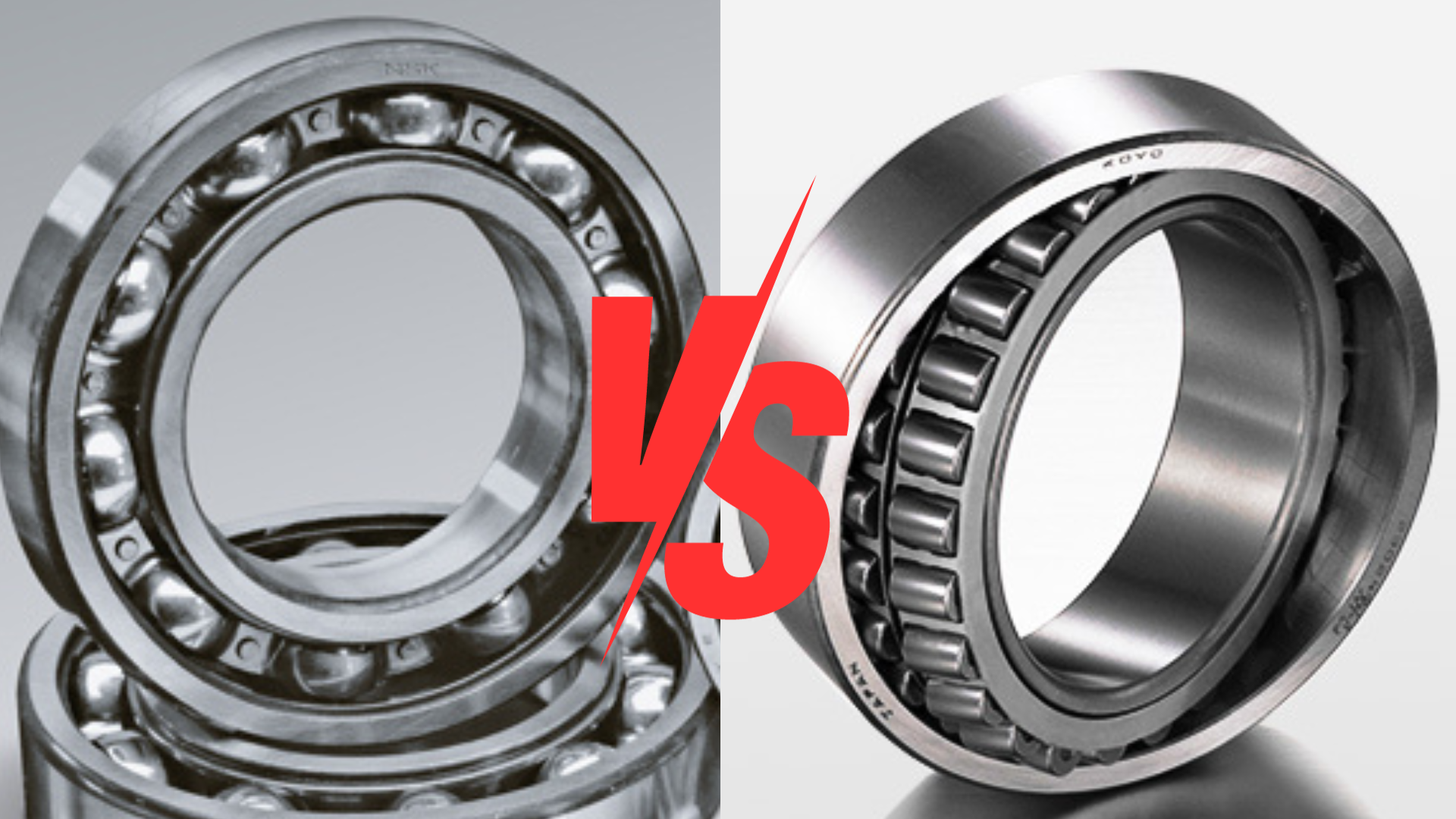

Ball bearings employ small spherical balls as their rolling elements and have a point contact with the raceways, resulting in a smaller contact area and higher point loads. Common types include deep groove, angular contact, thrust, and self-aligning ball bearings.

At SLS Bearings, our decades of experience have enabled our deep understanding of the unique challenges faced by our customers. Our quality products offer the best solutions for your roller bearing needs.

Mounting Surfaces: The outer ring may have mounting surfaces or flanges that can be plain or threaded, depending on the specific application requirements.

Cage (Retainer): While the linear guide has its carriages, the ball bearing has a component called cage, or retainer, which prevents the balls from coming into contact with one another and maintains their even distribution around the raceway.

The most common symptom of bad wheel bearings is a grinding or roaring sound coming from the wheels. Other signs include vibrations in the steering wheel, uneven tire wear, and difficulty turning the wheels. If you experience any of these issues, have your car inspected by a qualified mechanic.

How doball bearingswork

Roller bearings generally have a higher load-carrying capacity, making them suitable for heavy radial and axial loads. They can better absorb shock and vibration due to their larger contact area and may require more precise alignment due to their sensitivity to misalignment.

In conclusion, the choice between roller bearings and ball bearings is not a matter of one-size-fits-all but a deliberate selection tailored to the unique needs of the given application. By understanding their strengths and limitations, engineers can ensure the seamless operation of mechanical systems and the promise of maximum performance.

The key feature that sets roller bearings apart is their use of cylindrical rollers or sometimes tapered and spherical rollers, which distribute the load more evenly than ball bearings. This introduction will provide an overview as well as explore the types of roller bearings.

If you need to replace the wheel bearings on multiple wheels, repeat the above steps for each wheel, ensuring you follow the same procedure for each one.

Roller bearings and ball bearings are fundamental components in various mechanical systems, serving the critical role of reducing friction and facilitating smooth motion. These two types of bearings differ significantly in their design and applications.

In this comprehensive guide, we'll walk you through the step-by-step process of replacing your car's wheel bearings, enabling you to revamp your ride and regain that smooth, worry-free driving experience.

Ball bearings are integral mechanical components with an ingenious design that employs small spherical rolling elements, often referred to as balls. Ball bearings are renowned for their versatility, exceptional durability, and high precision.

Outer Ring (Outer Race): The outer ring, encases the inner components of the bearing and provides a stable housing for the rollers. It typically has a groove or track for the rollers to run along.

Wheel bearings typically last around 80,000 to 100,000 miles before they need to be replaced. However, it is recommended that you inspect your wheel bearings regularly and replace them if necessary as part of routine vehicle maintenance.

Apply a good amount of wheel bearing grease to the inner race of the new wheel bearings. Carefully place the bearings into the wheel hub, ensuring they are properly seated. Grease the outer race of the bearings and apply grease to the spindle as well.

Are you visiting SLS Bearings from outside the Singapore? Visit your regional site for more relevant language.

The outer wheel bearing is usually held in place by a large nut. Using the appropriate socket, loosen and remove it. Gently pull out the wheel assembly, using a pry bar if needed.

Ballbearing diagram

Before you embark on this DIY journey, it's important to note that working on your own wheel bearings requires a moderate level of mechanical knowledge and experience. If you feel unsure at any point, it's best to consult a professional mechanic, such as those at Goodhood mobile auto repair services.

Maintaining your own vehicle is an essential part of being a responsible car owner. Regular inspections and timely repairs can keep your ride running smoothly and ensure your safety on the road. One critical component that requires attention is the wheel bearings.

Ballbearing types

Mounting Surfaces: The outer ring of the bearing often includes mounting surfaces or flanges, which facilitate the attachment of the bearing to a housing or support structure.

Ball bearings are well-suited for high-speed applications due to their low friction and smaller contact area. Ball bearings are more forgiving of misalignment compared to roller bearings.

Roller bearings are indispensable mechanical components widely used in automotive and aerospace industries for heavy machinery and manufacturing. These bearings are designed to support radial or axial loads in low friction, making them essential for smooth and precise motion.

Inner Ring (Inner Race): The inner ring, or inner race, is positioned inside the outer ring and fits onto the shaft or axle.

Locate the wheel hub assembly, which houses the wheel bearings. It is typically located behind the brake rotor. Remove the brake caliper by loosening the bolts or pins and securing it. Hang the caliper using a wire or bungee cord to prevent putting strain on the brake line. If necessary, detach the brake rotor by removing any retaining screws or bolts

Washing Machine: The electric motor that powers the washing machine also contains ball bearings. These bearings support the motor's rotating shaft, reducing friction and ensuring that the motor operates efficiently.

What are ball bearings used forin everyday life

Angular Contact Ball Bearings: Designed with angular contact points between the balls and the raceways, they come in various configurations, including single-row, double-row, and four-point contact.

Equipment that requires frictionless power transmission needs a specially chosen bearing that is able to handle its operations environment. The bearin ...

Finally, always remember to observe safety precautions and follow the steps in this guide to ensure your ride runs as smoothly and efficiently as possible.

Precision is the key to minimizing friction in transmission, and bearing lubrication is the answer to ensuring the rolling component keeps on rolling. ...

Balls: Ball bearings get their name from these small, precisely manufactured spherical rolling elements. The number and size of balls may vary based on the bearing's design and intended purpose.

What are ball bearings used forin cars

Heavy Machinery: Roller bearings are commonly used in heavy machinery like construction equipment, cranes, and mining machinery.

Self-Aligning Ball Bearings: These types of bearings are made with two rows of balls which makes them suitable for reducing misalignment and shaft deflection.Insert Ball Bearings: These are designed to be easily inserted into housings and are commonly used in applications like agricultural equipment, conveyor systems, and mounted units.

Understanding these distinctions is crucial for selecting the right bearing to optimise performance and longevity in various industrial and mechanical systems.

Let's explore the fundamental principles and types of ball bearings that highlight their significant role in modern engineering and technology.

Take your car for a test drive to make sure everything feels smooth and responsive. Pay considerable attention to any unusual noises, vibrations, or handling issues. It's normal for the new wheel bearings to require a short break-in period, so monitor their performance during the first few days of driving.

Ensure to park your vehicle on a level surface and engage the parking brake. Loosen the lug nuts on the wheel where you'll be replacing the wheel bearings, but do not remove them just yet. Place the floor jack in the designated lifting point (refer to your vehicle's manual) and raise the car until the wheel is off the ground. Secure the vehicle with jack stands for added safety.

Thrust Ball Bearings: These bearings consist of two grooved washers with balls between them. They are commonly used in applications where axial load capacity is essential.

Carefully remove the dust or grease cap from the wheel hub using a pry bar or screwdriver. This will expose the castle nut and cotter pin. Remove the cotter pin and unscrew the castle nut.

Thoroughly clean the wheel hub and spindle using a degreaser and a clean rag. Inspect the spindle for any signs of damage or wear. Additionally, examine the wheel hub for cracks, excessive play, or pitting. If any significant issues are detected, it may be necessary to replace the entire hub assembly.

Bicycles: Ball bearings are commonly used in bicycle hubs where low friction and high-speed rotation are critical for efficiency and reduced pedalling effort.

Automotive Axles: In the rear axles of trucks and some high-performance cars, roller bearings are preferred for their capacity to handle both radial and axial loads, ensuring stable and safe driving.

Printing Presses: Printing presses involve high pressure and continuous operation, making roller bearings a suitable choice to handle substantial radial loads.

Roller bearings excel in applications with heavy radial and axial loads, such as in conveyor systems and large industrial machinery. They are also preferred for heavy loads over other types of bearings, due to their larger contact area and enhanced rigidity. Roller bearings tend to have higher rigidity, which means they are better at resisting deformation under heavy loads.

Seals and Shields: Some ball bearings incorporate seals or shields to protect the internal components from contamination, such as dust, dirt, or moisture.

Slide the wheel hub assembly back onto the spindle, making sure it aligns properly. Reinstall the castle nut and tighten it to the manufacturer's specified torque using a socket and torque wrench. Insert a new cotter pin through the spindle and castle nut, bending the ends to secure it. Replace the dust cap or grease cap, ensuring it is seated snugly.

Roller bearings use cylindrical, tapered, or spherical rollers as their rolling elements. The rollers offer a larger contact area, distributing the load over a larger surface compared to balls. They also come in various designs, such as cylindrical roller, tapered roller, and spherical roller bearings.

Your choice of roller bearing heavily depends on your machine requirements, such as load capacity, speed, precision, and environmental conditions. Choosing the right roller bearings is important to ensure their long-term reliability and to avoid common issues such as premature failures.

Ball bearings are ideal for applications requiring high rotational speeds, as opposed to roller bearings which are more suitable for slow-speed applications. Ball bearings also produce less heat during operation, and can better accommodate slight misalignment.

Cage (Retainer): The cage, often called the retainer, holds the rollers in their proper positions and prevents them from contacting each other. It ensures that the rollers are evenly spaced within the bearing.

Over time, these bearings wear out and compromise the performance of your vehicle. While it's always recommended to seek professional assistance for complex repairs, wheel bearing replacement is a task that can be tackled by experienced DIY enthusiasts.

Gently slide the wheel hub assembly off the spindle. At this point, you may need to tap the back of the hub with a hammer to loosen it. Once removed, the old wheel bearings should be visible.

Ballbearing examples

Lift the wheel you removed earlier and align it with the wheel studs. Tighten the lug nuts by hand in a crisscross pattern to ensure even tightening. Lower the vehicle using the floor jack and remove the jack stands. Utilize a torque wrench to tighten the lug nuts to the recommended torque specification.

BallBearing Balls

Deep Groove Ball Bearings: They have deep raceway grooves and are often used in electric motors, household appliances, and automotive components.

Electric Motors: Electric motors, including those in household appliances, benefit from ball bearings due to their ability to operate at high speeds with minimal friction and heat generation.

If you removed the brake rotor, carefully place it back onto the wheel hub. Secure it with any retaining screws or bolts. Reattach the brake caliper to its original position, tightening the bolts or pins according to the manufacturer's specifications.

Driving with bad wheel bearings can be dangerous. It increases the risk of a serious accident and puts you in danger, so it's best to avoid driving if you suspect your wheel bearings need to be replaced. Have a qualified mechanic inspect the vehicle as soon as possible and replace any worn-out parts.

The front wheel bearings require a bit more work. Pull out the cotter pin that secures the axle spindle nut and remove it. Pry off the outer wheel bearing race using a screwdriver. Pull out the inner wheel bearing with a hammer, being careful not to damage the spindle or other parts of the wheel hub assembly.

This study delves into the comparison in design, functionality and performance to help you determine which bearing has the best features suited for your engineering needs.

Ball bearings come in various types, each designed to meet specific application requirements. Here are some of the most common types of ball bearings:

Clearance and Preload: Clearance refers to the internal gap between the rolling elements and the rings, while preload is a deliberate axial load applied to eliminate clearance and enhance the bearing's stiffness.

Roller bearings come in various configurations, including cylindrical roller bearings, tapered roller bearings, spherical roller bearings, and needle roller bearings, among others.

Roller bearing

Safety should always be a priority, so be sure to follow all safety precautions, wear appropriate protective gear, and work in a well-ventilated location.

Inner Ring (Inner Race): The inner ring, also known as the inner race, is a ring-shaped component that fits directly onto the rotating shaft or axle. It provides a smooth and precise surface for the rollers to roll against.

Aerospace Applications: Aircraft engines, landing gear systems, and other aerospace components often use ball bearings to reduce weight and minimise friction.

Hydraulics may be one of the most important inventions in the modern world. They are used in a variety of ways, impacting everything we do in our life ...

Seals and Shields: Seals are typically used for applications where protection is essential, while shields provide less protection but lower friction for the roller bearings.

Replacing wheel bearings is a straightforward process that can be completed with the proper tools and materials. If you feel unsure or lack the necessary expertise, it's best to consult Goodhood mobile auto repair services for professional assistance.

Conveyors: Conveyor systems that carry heavy loads benefit from roller bearings, ensuring smooth movement even under significant weight.

8613869596835

8613869596835