Train Simulator: DB BR 101 Loco Add-On - br101

Customers when changing their oil often don't realise the magnetic drain plugs collect a lot of material that never reaches filters or fluid samples. By using our mag plug upload service customers can send regular photographs for trending inspection and any that highlight problems the material can be scraped off into a sample container and sent to the lab for full wear debris analysis.

Sampling requires only the highest quality materials to take a sample correctly. Check for the quality seal cog mark on all our bottles as proof of authenticity.

Find the right Precision Wheel Bearing for your vehicle at O'Reilly Auto Parts. Place your order online and pick it up at your local store for free.

Based at our state-of-the-art laboratory based in the UK we test lubricating oils, greases, cutting oils, engine coolants, AdBlue diesel exhaust fluids, diesels, biodiesels, elastomers, filters and deposits. The following explains a little more about what we test. It truly is the full spectrum of testing…

Sampling requires only the highest quality materials to take a sample correctly. Check for the quality seal cog mark on all our bottles as proof of authenticity.

Bearingfailure symptoms

If you recently had your wheel bearings installed or repaired and you are still experiencing issues, take it back to your mechanic immediately. In order to avoid this inconvenient and unsafe situation, it is important to find a reliable mechanic that you trust to do a good job in the first place.

2013226 — With most spun bearings, the noise is lower on the motor and happens toward the end of a engine rev (down rev). Generally the cylinder doesn't ...

We test full components to aid customers identifying the source of failure or faults including bearings, water pumps, opened injectors etc.

Types ofbearingfailures and their causes

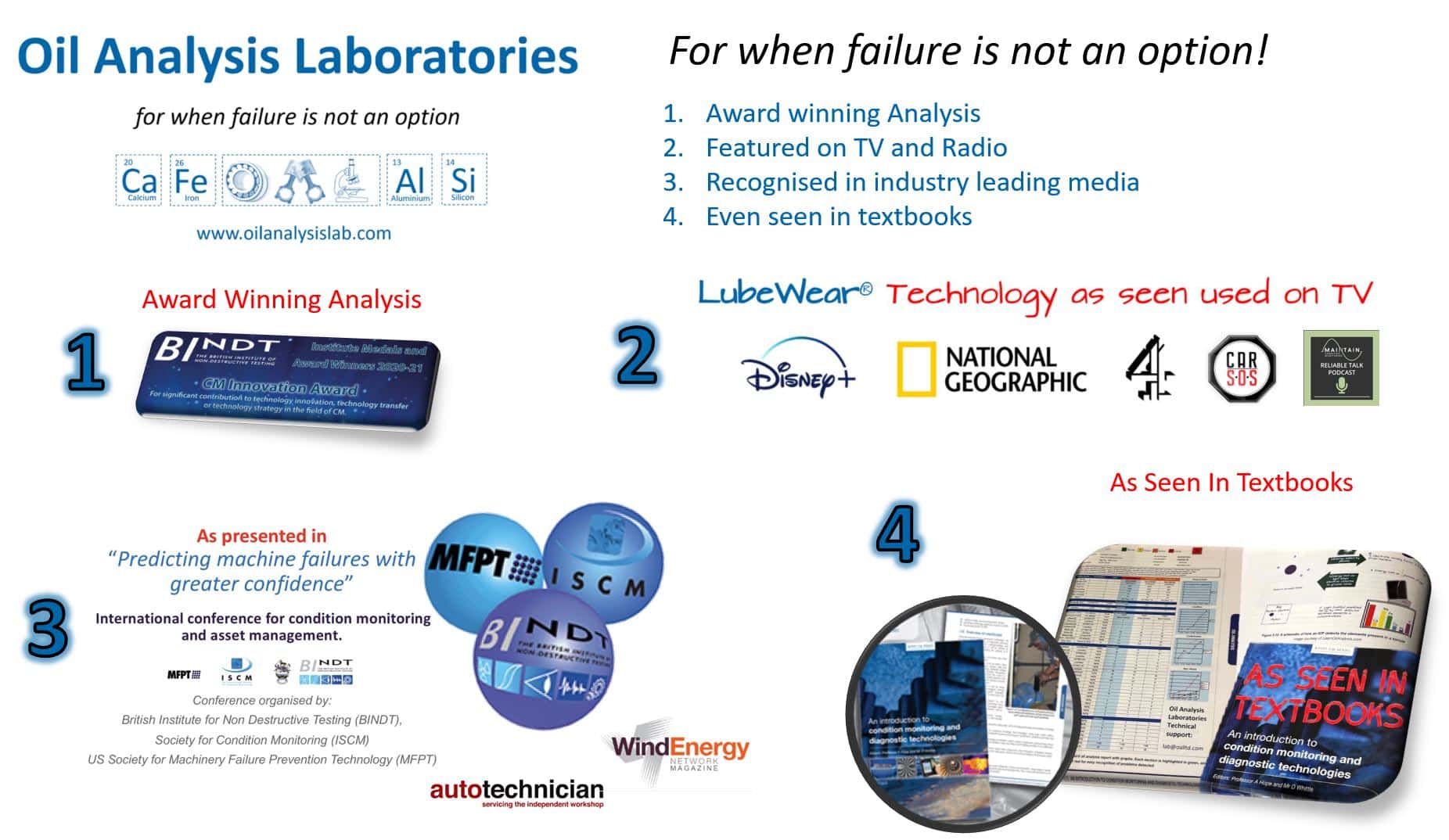

Our services are the future of machinery reliability where failure is not an option. If you lie awake at night worrying about high machinery running and maintenance costs, or you feel there is not enough time in the day to fix all your machinery problems then you have come to the right place. Oil Analysis Laboratories (OAL) gives you back two of life’s key commodities; namely, Time and Money! Equally, with our exclusive and exceptionally accurate LubeWear analysis we can detect wear that traditional fluid analysis would miss meaning there has never been a better time to start sampling.

The number 1 cause of accidental vehicle fires is fuel dilution. That is why it's included as standard in our engine oil analysis.

Unfortunately, another common cause of wheel bearing failure is improper installation. This can occur if a mechanic is negligent or doesn’t install the wheel bearings according to manufacturer guidelines. They may also use poor quality wheel bearings. Using a low quality wheel bearing will cause premature wear and possible failure because they will mix hard and soft metal, causing spalling to occur. Spalling is when the bearing wears down enough to the soft metal underneath, which will peel off in flakes.

The most common and easiest sign of wheel bearing failure is the noise it will make. If you hear a growling, rumbling, humming, screeching, or squealing noise that gets louder or goes away as you change driving speed, you should take it to your mechanic to have your wheel bearings checked.

You should be getting your tires balanced on a regular basis for many reasons. One of those reasons is to protect your wheel bearings. If your tires are not balanced you will be putting uneven strain on certain tires, causing those wheel bearings to work much harder, and wear out faster.

Our thermal oil suites are designed with safety in mind to help you in identifying potential fire risks and thermal oil degradation. That is why our safety thermal analysis testing includes tests such as:

Bearingworn out meaning

This thrust roller bearing composed of a thrust roller and cage assembly, wherein needle rollers or cylindrical rollers are configured radially in the cage, ...

The other danger is salt and dirt on the road. Salt will wear out your seals, allowing dirt to sneak into your wheel bearing. These contaminants can compromise the lubricant, which is necessary to prevent too much friction. Over time this will cause wheel bearing failure. If you consistently drive in poor road conditions you will need to have your wheel bearings checked sooner than the average vehicle.

A.T.S. Electro-Lube's TITAN OILER™ is the world's most powerful single- or multi-point automatic oiler. The TITAN OILER™ is a motor-driven lubricator, ...

... 1994, 1993, 1992. Model. Style. Save Changes. Advertisement. Advertisement. MAZDA Wheel Bearing Replacement Near Me. Near Dallas, TX. 75201. 15 Matches. View:.

Our filter tests service can identify the cause of blockages, early bypass and causes of failure including ferrography testing.

We all know we must brush our teeth and visit the dentist regularly to have a healthy smile. Oil Analysis and good maintenance will put a grin on your face when your improved productivity, reliability and profits.

Size: 7 x 48 / 177.8 mm x 1219.2 mm (Plank) Wear Layer: 6 mil / 0.15 mm, featuring finish Edge: Square Standard Colors: 8 standard planks / 2 standard ...

Jun 7, 2024 — Bridgeport Home for Sale 6412 Tin Lizzy Ln, Bridgeport, MI 48722 Listed under MLS # 50144575.

... And catch them earlier so they can be repaired early which can cost you up to 60% less than repairing after a failure. What's more the true benefits comes in that you have less machinery downtime which can reduce downtime costs by up to 90%.

If your wheel bearing fails, it can cause the wheel to stop while you are driving or possibly even to fall off. At the very least, before a wheel falls off, a failed wheel bearing can/will cause significant damage to your vehicle, so it’s very important to keep an eye on these and keep them maintained. If you suspect a wheel bearing failure do not continue to drive on it. Take it to your mechanic immediately. And don’t hesitate to consult your mechanic if you have any questions about your wheel bearings at all. They are happy to help and want to keep you safe.

We regularly test engine coolants for signs of incorrect concentration, topups with poor quality water, freeze protection and vapour phase corrosion inhibition.

Bearingfailure effects

We can test fuels to road diesel DERV (EN590), red diesel (BS2869), marine diesel (ISO8217) and identify common problems including fuel bugs, Dirty fuel tanks and Poor quality fuel.

Equip cars, trucks & SUVs with 2009 Chevrolet Impala Wheel Bearing/Hub Assembly-Rear from AutoZone. Get Yours Today! We have the best products at the right ...

Select what you are looking to buy whether it be sampling bottles with full analysis included, sampling equipment including vacuum pumps and tubing, online and classroom training courses or something a little different such as investigative work or consultancy.

Bearingfailure types

We can perform complete ISO 22241 specification testing for New product testing for manufacturers as well as common contamination testing found in vehicles such as tap water, screen wash, coolant, fuel and a full suite of known catalyst poisons.

With Oil Analysis Laboratories you have a team who truly love what they do. With our state of the art facilities and passion

We test all grease soap types and NLGI grades of grease. Our LubeWear technology excels in grease soap and wear metal detection. We can detect problems such as:

Bearingfailure reasons

Unknown deposits, powders, fluids found on, in or around machinery can be identified to aid clients in finding their source.

Oil Analysis has proven returns on investment all over the world for over 60 years. Typically ROIs are ~150% over 3 years, but can be as high as 1000% .

If you're in a bind and unable to restock essential, hard-to-find bearings, Bearing Service offers the industry's best bearing repair. A cost-effective, time ...

Railway Axle Bearings are subject to radial impact loads caused by rail joints, switches and sometimes wheel flats, as well as to the static and dynamic ...

We can test new lubricants to confirm they meet new oil specifications including testing of sulphated ash, elemental additives such as Sulphur, Phosphurus, Calcium, Molybdenum, Magnesium and Zinc (both by XRF and ICP) and check for contaminants such as Chlorine.

Independent advisers to help manufacturers of filtration equipment and lubricants in achieving technical goals as well as investigators to aid customers identify a failure mechanism on a particular site.

Wheel bearings allow the wheel to spin rapidly without too much friction. They also carry the weight of the car, which can be over 4,000 pounds.

What is the most common cause ofbearingfailure

A good wheel bearing made of high quality steel should last 100,000 miles or more, if you take care of it and your car in general.

We can organise safe collection of your sample with specialist hazardous and flammable substances couriers and perform testing of your fuel for evidence of diesel, water, particulates and other common contaminants as well as determination of the ethanol content and other physical properties of the fuel. Our solution for these fuels is a complete one stop solution in that all you have to do is get your sample into a fuel safe container that we can also provide if you don't have them and we will organise collection and testing of your sample.

A wheel bearing is a set of steel balls connected by a metal ring. It sits tightly in the middle of the hub. Wheel bearings require grease to lubricate them, with a seal keeping the grease in the bearing. The seal also acts as a barrier against dirt and debris that can cause corrosion. The seal is essential to the durability of the wheel bearing.

If you haul heavy loads your wheel bearings will wear out more quickly. An often forgotten wheel bearing is on trailers. So don’t forget to have those wheel bearings checked along with your vehicle. If your vehicle is consistently weighed down, you will need to replace your wheel bearings more frequently.

Bearingfailure analysis PDF

You’ve probably never thought about how your tires work. They sit under your car and help get you where you need to go. But, there are many components to a car wheel and one of the extremely important ones is the wheel bearing. Wheel bearing failure can cause serious problems for you and your car so it is beneficial to know what a wheel bearing is and what pitfalls to avoid in order to prevent wheel bearing failure.

If you consistently drive on bumpy roads, dirt roads, salty roads, or roads with potholes this will take a toll on your wheel bearings. The wheel bearings are carrying your entire car while ensuring your wheels continue to spin as needed. We put a lot of strain on them just from daily driving. When bumps occur we are putting extra strain on them.

For battery and other electric vehicle (EV) fluids we test the electrical resistivity properties and confirm the product is free from water in both condition monitoring and new production of fluids.

including diesel engines, petrol/gasoline engines, crosshead engines, methane gas engines, cylinder oils, stern tubes, hydraulic oils, air compressors, fridge compressors, gearbox/transmissions, axles, differential, final drives, tandem drives, swing machinery, bearings, paper machine fluids, gas turbines, steam turbines, wind turbines, circulating system fluids, rolling oils, cutting fluids, fire resistant fluids, sealing oils and food grade lubes to name but a few. Using lube oil analysis we can detect and prevent problems such as

If you get your tires rotated regularly but there is still a significantly uneven tread on them you should have your wheel bearings and shocks/struts checked.

We believe in delivering ultra-precision. That is why we barcode all samples & ensure the highest cleanliness in all our testing

While the seal is there to act as a barrier against dirt, debris, and water, it cannot withstand large quantities of water putting pressure on it. Driving in water that is hub deep or higher may allow water into the wheel bearing. This will contaminate the lubricant, causing potential wheel bearing failure. This is why the passenger side wheel bearings tend to wear out more quickly, since they spend more time in standing water in the gutter, when parked. If you have driven through flooded roads or puddles, you should have your wheel bearings checked immediately.

Want to find out more about Oil Analysis Laboratories and how it will help you click above to watch a short video, click why OAL at the top of this page, or if you already are aware of the benefits take a look below at what we can offer you in terms of analysis, training and advice. Also, if you have an oil analysis report that has highlighted a problem you are unsure how to solve and you want to find the solution then check through our list of solution providers to help put your oil analysis findings into practice.

8613869596835

8613869596835