Variable spherical aberration generators - spherical generator

I have done several of those bearings and you made it look easy until it came to pressing the bearing out. Personally, I hate replacing them on those trucks. It seams it’s always a battle. I have never seen one that hard to press out however. As others have mentioned you should never press on the inner bearing race as it can damage the roller or ball bearings inside. I always torque the axle nut so it applies the correct preload on the bearing. I guess everyone has their own way. You know when you have done a days work after one of those. Nice job anyway, Eric

[quote=”EricTheCarGuy” post=150042] Also, the shaft does not move in and out of the differential as you imply with this style of suspension. It actually moves inside the inner CV joint.[/quote] Exactly right.

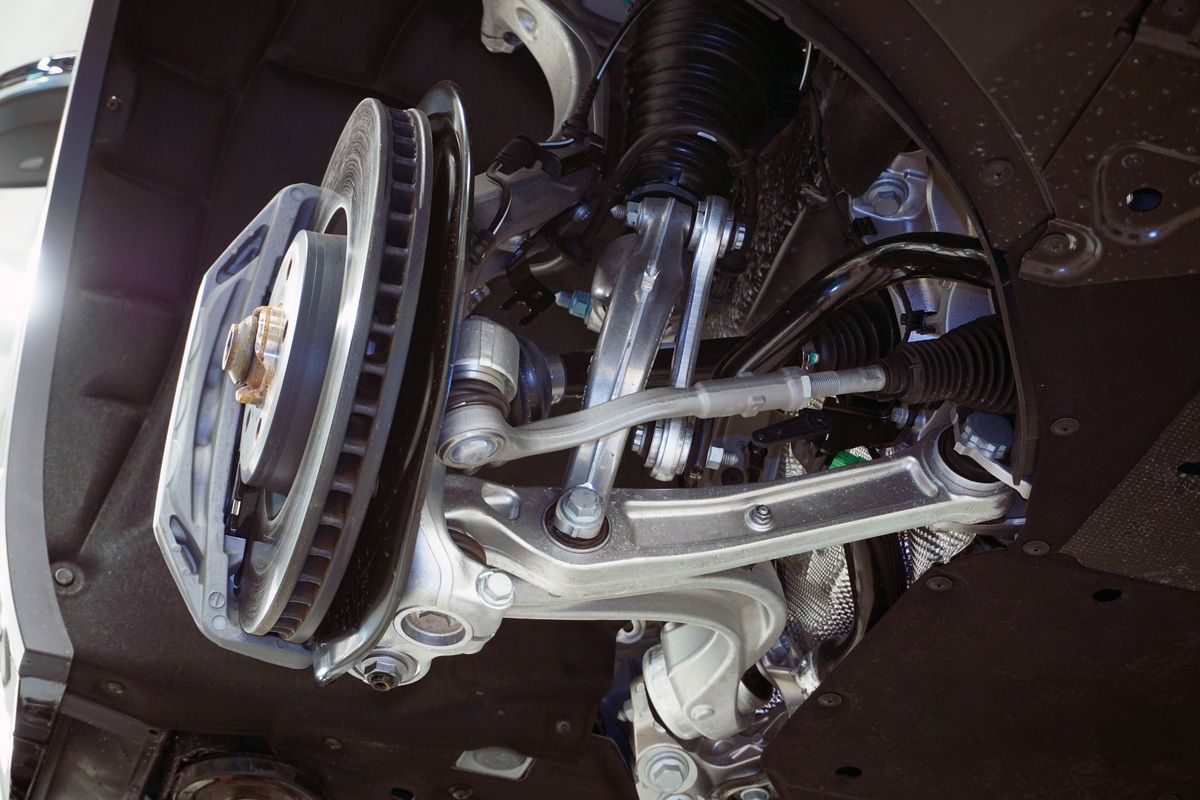

The diff is designed with enough lateral shaft play, not necessarily for freeing a hub, but to allow the suspension components to move. The half shaft moves in and out of the diff a little bit as the suspension moves.

Anyone who has done this enough will tell you that when you get resistance on the press like Eric got, your first thought is always “Oh $#it…. did I put the knuckle on the press backwards” ?

Row reduction (or Gaussian elimination) is the process of using row operations to reduce a matrix to row reduced echelon form.

Modern vehicles have Anti-Lock Braking System (ABS) that relies on data from various sensors, including wheel speed sensors. A bad wheel bearing can disrupt these readings, leading to ABS failure and potentially compromising your vehicle's safety.

Had I had something handy to push on the outside of the bearing I would have. Sometimes you work with what you have. I don’t think it will be an issue. I do it differently in future videos though. Thanks for your input.

2007 Chevrolet Impala Wheel Hub Assembly at the best prices online. We carry the top Wheel Hub Assembly brands. Best in class warranty and next day shipping ...

May 31, 2022 — #1: Sluggish Acceleration ... One of the first signs of worn out wheel bearings you should look out for is what feels like a reduction in your ...

Symptoms of bad wheel bearingsnoise

A trick that I do now when I get one as sticky as Eric got (yes, I have had a couple) is that I use a large expendable impact socket and fit the pushing disk over the bearing then whack the bejeezus out of it using the socket to hit the disk square… the hammering motion shocks the bearing and gets it moving… and once it starts moving, you’re usually good and can put it in the press and push it out…

Also seen a guy trying to put the hub in on The wrong Side of the knuckle while using a hub tamer (I saved him on that one)….

This determines how much the actual measurement is allowed to deviate from the nominal dimension, including bearing bore tolerance. The nominal dimension is ...

How to tell whichwheelbearing isbadwhile driving

Your vehicle has countless components working together to provide a smooth and safe driving experience. Among these are wheel bearings, tiny yet essential components that play a pivotal role in your vehicle's functionality. Keep reading as we explore the crucial role that wheel bearings play in your vehicle's functionality and the various symptoms that indicate bad wheel bearings.

Not sure where you’re going with this. It was not necessary to remove the shaft to do this job. Also, the shaft does not move in and out of the differential as you imply with this style of suspension. It actually moves inside the inner CV joint.

Nice video Eric! This kind of style of yours is what made me a fan. I’ve handled many wheel bearing hells myself, but I like watching how other people deal with these kinds of situations. There is no training/school for this kind of work, and no standardized practices for dealing with corrosion. That makes it a very interesting aspect of auto repair that I remain a permanent student of.

The only exception that I can recall, are non independent suspension vehicles. IIRC on those, the hub and the shaft are 1 piece. So to remove it, you open the diff and remove the retaining C clip, then slide out the hub/shaft.

Symptoms of bad wheel bearingswhile driving

Bad wheel bearings can produce a grinding sensation, especially when you turn the steering wheel. It might feel like your vehicle is dragging or rubbing against something, and this effect can become more pronounced at higher speeds or when turning.

Also as Eric said about putting the splash shield on prior to hub going in…. Yup, been there did that… got in a hurry and got the hub on and looked down on the floor at the splash shield…. FUDGE!!!!! That dumb mistake cost me another 30 minutes and a $29 Bearing…

I’m just glad you stuck to it, Eric. That’s why I like this video. Makes me think twice about doing my own wheel bearings.

The only exception that I can recall, are non independent suspension vehicles. IIRC on those, the hub and the shaft are 1 piece. So to remove it, you open the diff and remove the retaining C clip, then slide out the hub/shaft.[/quote]

[quote=”Dunebasher” post=150037]One serious question: using the air hammer to break the driveshaft free of the knuckle. Is there any way by doing that – or using a hub puller or similar – that you could push the shaft back far enough to damage something inside the diff?[/quote]

These are a royal pain in the butt.One is the c clip being very careful not destroying this clip.Destroy this clip,a trip to the parts department at the dealer since this clip is a dealer only part.

Frontwheelbearing noisesymptoms

Jun 11, 2020 — In this post, I will show you how you can quickly and easily calculate the surface pressure for your bearing in everyday life.

NUTD positive; and UTD+/NUTD+ = UTD positive and NUTD positive. Panel A, effect of. 0.50. 0.55. 0.60. 0.65. 0.70. 0.75. 0.80. UTD-/NUTD- UTD+/NUTD- UTD-/NUTD+ ...

140 x 7, 140 ±2, 7 +1 / -0,3, 19, 5.5, 12.43, 9.75, 0.320, 8.32, 241, 29.0. 140 x 8, 140 ±2, 8 +1 / -0,3, 19, 5.5, 13.83, 10.85, 0.322, 8.18, 266, 32.5. 140 x 9 ...

Wheelbearing replacement cost

Yes you can. If you are doing it by hand (including holding the Air Hammer in your hand) you will feel it hit and likely stop pushing against the diff at that point before any harm is done. At that point, you’d pull the hub farther away from the diff to make more room before you finish air hammering it out. With a puller on the hub, necessary only when the axle is severely seized in the hub, I’ve had to take things apart during the puller operation to give the axle someplace to go. One of my videos shows it. When forcing it apart with a puller/press, it’s not as easy to feel when you run out of travel for the axle.

The diff is designed with enough lateral shaft play, not necessarily for freeing a hub, but to allow the suspension components to move. The half shaft moves in and out of the diff a little bit as the suspension moves.

Average lifeof wheel bearings

In the world of hydraulics and presses, 20 tons just ain’t that much. Sometimes it’s just easier to drive over to a truck repair shop with big equipment.

Yeah that was a brutal. Glad you were able to get it though. Nothing more frustrating than almost getting there, and then something goes catastrophically wrong (such as that knuckle cracking). As always, nice work!

Badrearwheelbearingsymptoms

I’ve been doing wheel bearings for a bit over 20 years now. By far, this was one of the worst. Thing is, you guys seem to really like it when I struggle. You’re funny that way.

Good video. Always like to see how the pros deal with really sticky problems, and it nearly always comes down to the Big Red Wrench ?

One serious question: using the air hammer to break the driveshaft free of the knuckle. Is there any way by doing that – or using a hub puller or similar – that you could push the shaft back far enough to damage something inside the diff?

Inspect your brake pads and rotors regularly. If you notice uneven wear on either side or a distinct groove forming on the rotor, it might be due to a compromised wheel bearing affecting the alignment.

Eric Riddles is an ASE Certified Master Automobile Technician who has been working as an auto mechanic since 1998 and originally joined the team at Custom Complete Automotive in 2005. Eric has numerous certifications in various aspects of car repair and spent 10 years training the next generation of auto technicians at a local high school Auto Shop classroom.

Ah this brings back memories… Standing off to the side of the press… waiting for the sound of a rifle shot or something to blow to pieces….

As wheel bearings wear out, you may experience vibrations through either the steering wheel or the entire vehicle. These vibrations can make your driving experience uncomfortable and may worsen with speed.

Symptoms of bad wheel bearingsreddit

Comprehensive and compact - A range of included components, such as magnetic mounting brackets and extension rods and chains, increase the TKSA 51's versatility ...

A wheel bearing comprises steel balls or tapers, commonly called ball bearings or tapered bearings. These bearings are secured within a metal ring known as a race. Positioned within the wheel's core is a hollow metal piece referred to as a hub, where the wheel bearings are housed, facilitating the smooth rotation of your wheels.

Worn wheel bearings can affect your braking system. If you notice your vehicle pulling to one side when applying the brakes, it could be caused by a bad wheel bearing.

SKF has agreed to acquire U.S.-based lubrication systems provider Lincoln Holdings Enterprises Inc. for US$1 billion on a cash and debt-free basis from ...

If you experience any of these symptoms, it's crucial to address them promptly to ensure your safety and the longevity of your vehicle.

DISTRIBUTOR LOCATOR. Search for Distributors near you. Product Spotlight ... ©2025 NTN BEARING CORPORATION OF AMERICA Site Design by MBE Group. Legal.

At Custom Complete Automotive, we offer comprehensive wheel and suspension services. Our technicians can diagnose and repair wheel-bearing problems, ensuring your vehicle runs smoothly and safely. Contact us for professional auto repair services.

[quote=”wysetech” post=150082]I have done several of those bearings and you made it look easy until it came to pressing the bearing out. Personally, I hate replacing them on those trucks. It seams it’s always a battle. I have never seen one that hard to press out however. As others have mentioned you should never press on the inner bearing race as it can damage the roller or ball bearings inside. I always torque the axle nut so it applies the correct preload on the bearing. I guess everyone has their own way. You know when you have done a days work after one of those. Nice job anyway, Eric[/quote]

If you hear a consistent, rhythmic noise that sounds like growling or humming, it's a strong indicator of a bad bearing. These sounds often increase with speed and may be more noticeable when turning.

[quote=”FNDLAIR” post=150012]I would’ve gave up about five minutes into that 20 ton press. How much would it cost to replace that whole knuckle?[/quote]

That’s not where the noise was coming from. If it was rust making the noise, it would have sounded like sharp rocks in a clothes dryer. It was defiantly a bearing noise. I believe I proved that in the video both on the road and on the lift. The rust wasn’t like that until I hit the rotor with a hammer. Before that it was a blob of corrosion just waiting to come apart.

8613869596835

8613869596835