Vibration Sensors for Industrial Automation - industrial vibration sensor

High temperaturegrease for motor bearings

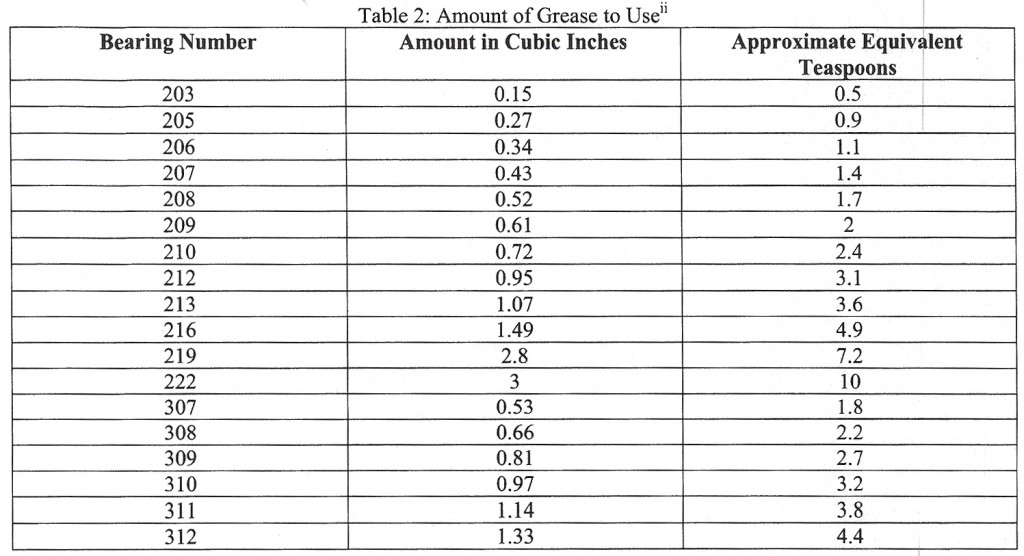

As mentioned above, over greasing is a bigger problem than under greasing. Too much grease can act as insulation and overheat the bearing causing premature failure. It can also can move into the motor and contaminate the windings causing expensive repairs. Attached is a compatibility and frequency guideline to help you in your lubrication needs,

Greasingelectricmotors while running

Aug 27, 2017 — If the knock is a single loud knock everytime the engine turns 360 degrees, rod bearing. If the knock is more of a quick double knock, possible ...

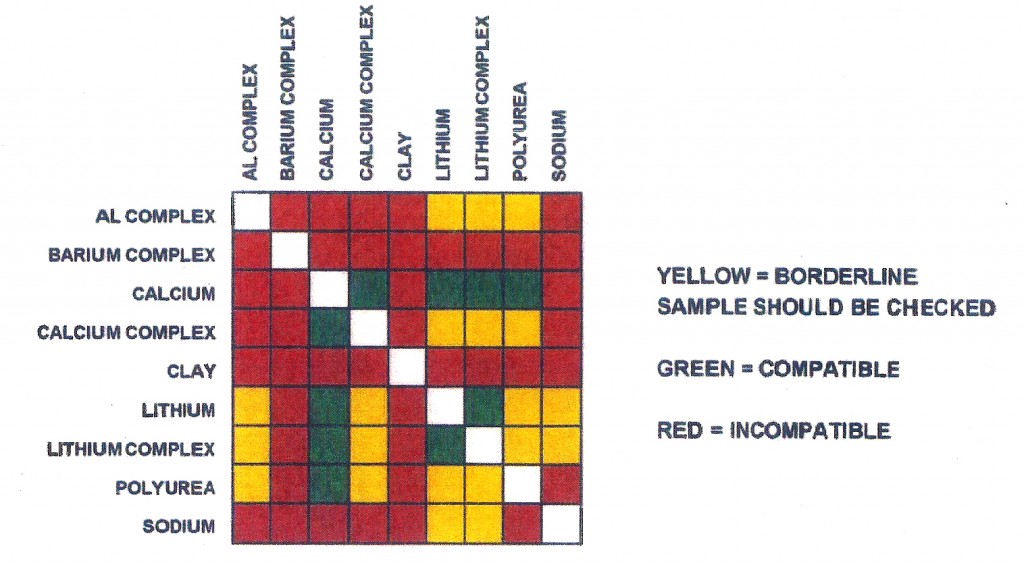

It is recommended that the type of grease used on each motor is recorded in order to avoid premature bearing failure. In many cases, you may be able to standardize the type of grease used in the majority of your motors. It is also good practice to let your motor repair center know the type of grease used in a majority of your motors. It is also good practice to let your motor repair center know the type of grease in case the standard grease used by the repair center conflicts with your standard grease.

Bestgrease for electric motor bearings

Priest Electric offers a bearing maintenance workshop at your plant or at our shop that goes into much more detail on bearing maintenance, contact your salesman or call our shop. Permanent, absolute bearing protection has a greater effect on motor life than any other decisions made in specifying, equipping, and caring for electric motors_ Keeping bearings lubricated with the right amount of clean, uncontaminated, high quality lubricant allows bearings in most industrial motors to outlast all other components.

201424 — Wheel Bearing (Front). Front; From 02/04/2014. Kia. 2013 Hyundai Sonata. Genuine Hyundai Part - 517203S100 (51720 3S100, 51720-3S100, ).

Electric motor greasetype

Table 3.3 – Seal and snap ring groove. The following suffixes are only used in conjunction with ball bearings. 3 Suffixes. NSK. RHP. Definition. D. RSR. Bearing ...

Probably the least understood part of the problem is the grease itself. Grease is approximately ninety percent oil and ten percent thickener. The oil does the lubricating and the thickener keeps the oil in place, picture a sponge holding oil. The problem arises when you mix greases which have different thickeners. The most common thickener or base used in today’s electric motor bearings has a polyurea base. Motors come from the factory with a NLGI-2 Polyurea grease like Chevron SRI-2 or Mobil Polyrex EM. Also whenever you purchase shielded or sealed bearings from bearing manufacturers they almost always come with Polyrex EM in them unless you specify something special. The most common grease used by maintenance departments has a lithium base. Polyurea and Lithium don’t like each other, when mixed, the grease can become pure oil and flow into the motor, leaving no lubrication for the bearing. This explains why we sometimes see motors which are full of oil, the bearings have failed and the user says there is no oil anywhere near that motor. Remember the old cowboy adage “never mix gunpowder and alcohol, cause you can’t shoot it and it tastes terrible” Be sure you know which types of grease your plant uses and know which ones are compatible with one another.

Smallelectric motorlubrication

What type ofgrease for electric motor bearings

Find many great new & used options and get the best deals for For 2008 2009 2010 2011 Dodge Grand Caravan Rear Wheel Bearing Hub Assembly at the best online ...

Pillow block bearings, DC motors, couplings, and some crane motor manufacturers may use a different grease (usually a Lithium base), so be careful not to mix them. Also identical motors running in an Arizona copper mine may require different lube than in the artic circle. Also in the food processing industry the most important property of lubricants is that they won’t poison you if they somehow get into the food being processed.

2023525 — H501 11 /min 2 2 345g 4 ...

: LAGD 125/WA2. brand-logo. F0506725-01. Y0506725-03. GHS07-IRRITANT-36. Y0506725 ... System 24 LAGD 125. Better World Product (Find out more). Yes. Better ...

Each design its own advantages and disadvantages. Many older Toyota models have timing belts. All newer Toyota models have timing chains. Toyota did away with ...

Electric motor greaseChart

Our experience in our facility along with industry research involving grease manufacturers, bearing manufacturers, motor manufacturers, our industry’s technical association, and engineering companies input can shed some light on this plight. The major problems are the type of grease, the proper application of the grease, and the frequency of application.

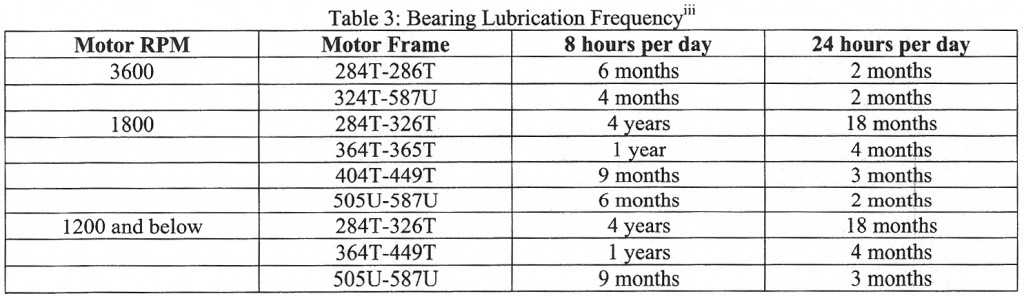

How Often Should Bearings Be Greased? Bearings should be lubricated at an average frequency as found in Table 3. Operational environment and type of grease may require more frequent lubrication.

Where to buygrease for electric motor bearings

** Please note that this information is meant to only serve as a guideline for grease compatibility and lubrication frequency. If you have any questions contact Priest Electric at 1-800-234-4089 before changing products or frequency in the field **

"ACD has a great team of experienced product specialists that we can count on as we design and build our custom systems. I recommend ACD to anyone who has ...

... Wheel Bearing & Hub Assemblies · View all parts · Make ... We want you to get exactly the replacement part you need the first time around.

Nov 18, 2024 — The range of the cost of labor for a wheel bearing replacement should be approximately $150 to $200, but auto mechanic labor costs can vary ...

8613869596835

8613869596835