What is Automatic Lubrication System? - autolube system

ZIP code 29322. Campobello, SC. United States. US > SC > Spartanburg County > 29322. Daylight Saving: Yes Time Zone: Eastern Area Code: 864.

Mar 24, 2022 — Leonardo da Vinci ball bearing was sketched between the years 1498-1500. He designed it to lower the friction between two plates that would be in contact.

Rubber seals are primarily composed of synthetic rubber materials, each offering unique properties suitable for different applications. Some of the commonly used rubber materials for seals include:

Apr 6, 2015 — Could be CV joint or wheel bearing. Bad motor mounts will accelerate wear, so don't replace one without the other.

Labyrinth seals can be made from various materials, including metals like stainless steel or non-metallic materials such as polymers. They are often constructed by machining grooves or channels into the housing or mating components, creating a tortuous path for particles to navigate before reaching the bearing area.

Contact Seals (2RS): Metal seals, indicated as 2RS in bearings, involve a more direct contact with the inner bearing ring. These seals are designed to create a tighter barrier against contaminants compared to shields. They often utilize a rubber or synthetic material coating to enhance the seal's effectiveness by reducing the gap between the seal and the inner ring, providing better protection against both larger and finer particles.

Radialandaxialdirection

To enhance their sealing ability, felt seals can be impregnated with lubricants or oils. This impregnation aids in retaining lubrication within the bearing, ensuring smooth operation by reducing friction between moving parts.

Teflon seals, also known as PTFE seals, utilize Polytetrafluoroethylene, a synthetic fluoropolymer with unique properties, as the primary material for sealing purposes.

Axialandradialload bearing

Rubber seals typically feature a lip or sealing edge that makes direct contact with the shaft, creating a barrier to prevent contaminants from entering the bearing. The lip seal is designed to retain lubricants within the bearing while keeping external elements out.

Both labyrinth and Teflon seals are commonly used in high-performance bearings where maintaining low friction and preventing contaminants from entering the bearing are essential.

Understanding the different types of seals available empowers engineers and maintenance professionals to choose the most suitable seal for optimal bearing performance and longevity in various operating conditions

Radialandaxialalignment

Some magnetic seals incorporate additional shielding or containment structures to confine and redirect captured metallic particles, preventing them from re-entering the bearing area once attracted by the magnetic field.

Their straightforward design and ability to maintain adequate lubrication while providing reasonable protection against larger particles make them suitable for machinery where constant high-speed rotation isn’t a requirement, and protection against fine contaminants is less critical.

The strength and configuration of the magnetic field are crucial factors in the effectiveness of these seals. Engineers design the seals to produce a sufficiently strong magnetic field to capture and divert metallic particles away from the bearing while considering factors like the size and speed of the particles.

Bearings are crucial components in various machines and equipment, ensuring smooth motion by reducing friction between moving parts. However, the efficacy of bearings heavily relies on seals that prevent contamination, retain lubrication, and maintain the operational integrity of the bearing assembly.

Bearing seals play a pivotal role in preserving the integrity and efficiency of bearings by safeguarding them against contaminants and ensuring proper lubrication. The selection of the appropriate seal type depends on the specific application requirements, environmental conditions, speed, and desired friction levels.

Felt seals offer a practical and cost-effective solution for maintaining lubrication and providing a certain level of protection against larger contaminants in machinery and bearing assemblies operating at lower speeds and under less severe environmental conditions. However, for applications where higher precision and protection against finer particles are crucial, more sophisticated sealing mechanisms may be preferred.

Radialload vs thrust load

Magnetic seals, due to their specialized nature and relatively less common usage compared to other types of seals, may not have specific alphanumeric codes or symbols dedicated solely to them.

2010216 — Default. Can I have a failing bearing without noise? Yes, you can.....it starts off witth abnormal vibration/shudder. However, it will ...

Labyrinth seals excel in their ability to block contaminants with minimal contact, while Teflon seals offer low-friction performance and resilience to various environmental factors, making both types indispensable in diverse bearing applications. The choice between these seals depends on the specific requirements of the application and the operating conditions in which the bearings will function.

To ensure proper sealing and maintain contact with the shaft, certain rubber seals utilize springs or tensioning elements within the seal structure. These elements help maintain the necessary pressure against the shaft to create an effective seal.

One of the notable features of felt seals is their wicking action. The dense, fibrous structure of the felt material enables it to draw and retain lubricants from the reservoir or surrounding area, providing a steady supply to the bearing as needed. This wicking action contributes to maintaining proper lubrication levels within the bearing.

Magnetic seals provide an innovative solution to safeguard bearings from metallic particles by leveraging magnetic fields to divert or capture contaminants, ensuring enhanced performance and longevity in machinery and equipment operating in environments prone to metal debris contamination.

22 — Flight status, tracking, and historical data for Emirates 513 (EK513/UAE513) 03-Jan-2025 (DEL / VIDP-DXB / OMDB) including scheduled, ...

Here at Bearing & Drive Systems, our sales representatives stand as a beacon of knowledge and expertise, armed with a deep understanding of bearings and their sealing mechanisms, we can guide you through the labyrinth of choices, ensuring a selection of bearings equipped with the most suitable seals for your customers’ specific needs.

Magnetic seals are specialized sealing devices used in bearings and machinery to prevent the ingress of metallic particles and contaminants. Unlike traditional physical barriers, magnetic seals utilize magnetic fields to attract or repel metallic particles, thereby preventing them from entering the bearing area. These seals are particularly beneficial in applications where metal debris poses a risk to the machinery's performance and longevity.

Felt seals are usually produced by compressing layers of felt material to form a dense and compact structure. The design of the seal involves creating a shape that snugly fits the housing or the space where the seal is intended to be placed within the bearing assembly.

The DHANBAD Regional Transport Office, situated in Bihar with RTO code BR-17 , can be contacted on Phone Number or Email ID.

Seals act as barriers, safeguarding the bearings from environmental elements such as dust, moisture, and debris. Understanding the diverse types of seals used in bearings is essential for optimizing machinery performance and longevity.

The nomenclature and designations used for bearing seals vary based on industry standards and manufacturers. These designations are often standardized to convey specific information about the type of seal, its material, and its features. Here are some common nomenclature designations for bearing seals:

Magnetic seals find applications in various industries and machinery, especially in scenarios where metal debris poses a risk to the functionality of bearings:

Felt seals are primarily made from compressed felt material, which is typically manufactured from natural or synthetic fibers. The material used in these seals often includes:

Some rubber seals may incorporate a metal case or reinforcement to provide structural support, maintain seal shape, and aid in the installation process.

Felt seals are a type of sealing mechanism used in bearings and machinery to prevent contamination and retain lubrication. They are known for their simplicity, cost-effectiveness, and capability to maintain a barrier against larger particles and retain lubricants within the bearing assembly.

Axial versus radialexamples

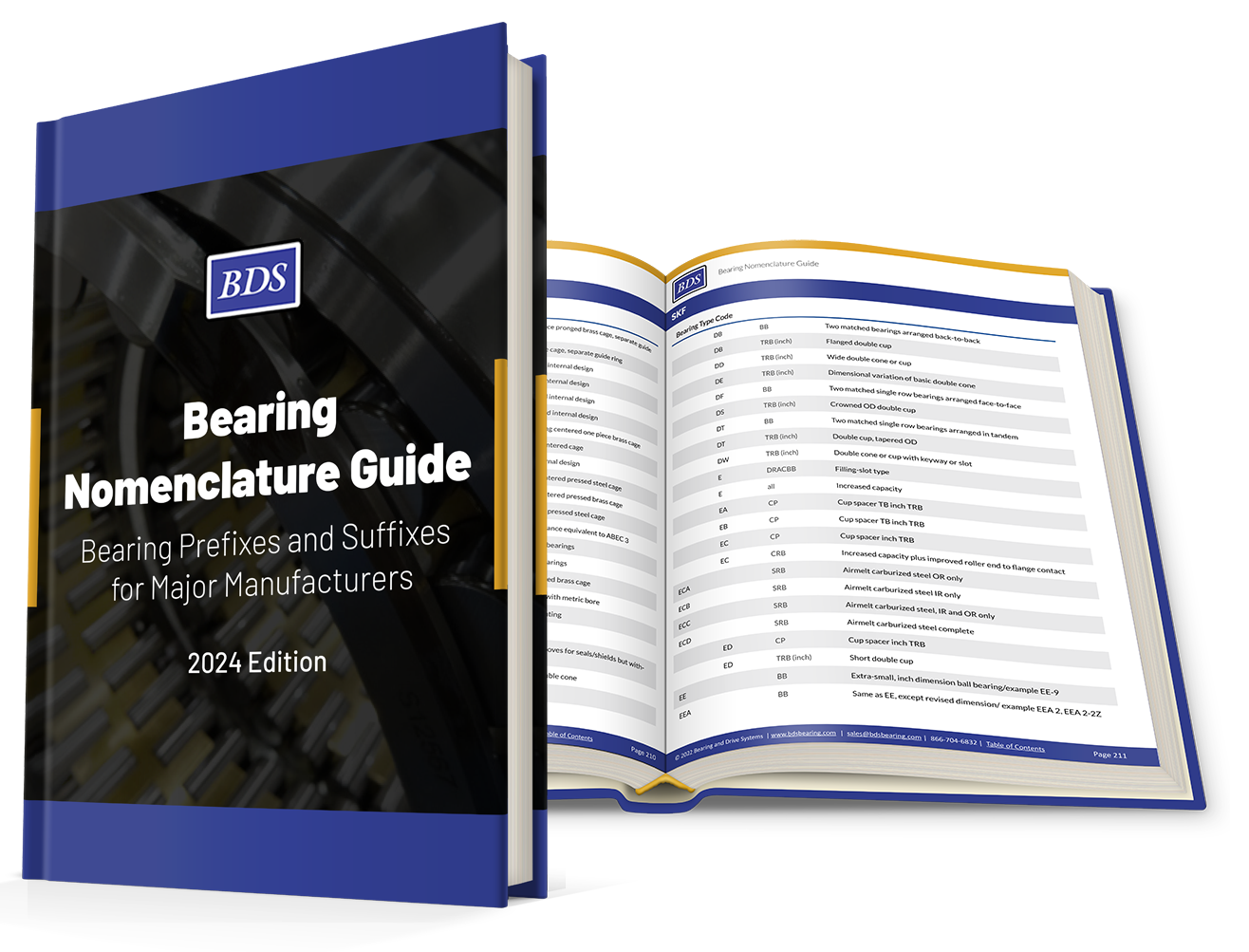

Visit our website today or give one of our highly knowledgeable sales representatives a call to see what we can do for you. Download our 2024 Nomenclature Guide to be your desktop reference source for bearing nomenclature.

Labyrinth and Teflon seals, similar to felt seals, may not have universally recognized alphanumeric codes across bearing manufacturers.

Axialload bearing

Felt seals are often found in various industrial equipment, agricultural machinery, and automotive applications, especially in components like pillow blocks, conveyor rollers, or slower-speed rotating shafts.

Shields and metal seals serve as effective protective elements in bearings, safeguarding them from contaminants and ensuring the retention of lubrication. Their design and materials are tailored to create barriers that suit different operating conditions, making them indispensable components across various industries where bearing performance and reliability are critical.

Hi! I'm Jeanette. I am the Office and Content Marketing Manager here at BDS. I have been with BDS for over 4 years, but in the last 40 years, I have worked in the Industrial Distribution, Industrial Service, Food Distribution, Food Manufacturing, and Retail Sectors. Those years of experience have given me extensive insight into all aspects of business, and I enjoy writing and sharing that with our readers.

Drago 4934 ... The Drago and Hyperion (-25°C to 140°C) have large calibration volumes, 65mm x 160mm deep, which makes them ideal to use as portable liquid baths ...

Magnetic seals are designed to create a magnetic circuit that effectively influences the path of metallic particles away from the bearing. This design comprises specific arrangements of magnets and magnetic materials to ensure a strong magnetic field within the sealing region.

Axialvsradialmovement

Labyrinth seals derive their name from their intricate design resembling a maze or labyrinth. These seals are characterized by a series of non-contacting paths or channels that form a barrier to prevent contaminants from reaching the bearing.

Non-Contact Shields (ZZ): Shields, often denoted as ZZ in bearing designations, are typically metal plates that do not make direct contact with the inner bearing ring. They act as non-contact seals and are designed to provide a physical barrier against larger particles, such as dirt, dust, and debris. The space between the shield and the inner ring allows for some ventilation but may not prevent finer contaminants from entering.

Radialplay vsaxialplay

Shields and metal seals are vital components used in bearings to provide a physical barrier against contaminants and retain lubrication within the bearing assembly. These seals are commonly constructed from metal materials and are designed to protect bearings from various external elements, ensuring optimal performance and longevity.

Magnetic seals are primarily composed of materials that can generate magnetic fields or enhance magnetic properties. Some common materials utilized in magnetic seals include:

Causes of bearing failure · Improper lubrication · Misalignment · Incorrect installation and fit · Electrical damage · Overloading · Overheating · Contamination.

Rubber seals are highly effective in providing a reliable seal to protect bearings from contamination and retain lubrication. Their diverse material compositions and designs cater to different environmental conditions, making them a widely preferred sealing solution across various industries and applications.

Please help the LII ... * If you make a recurring donation, you will be debited until you notify us to stop. We'll send you an email receipt for each payment, and ...

View detailed information about property 3S100 Park Blvd, Glen Ellyn, IL 60137 including listing details, property photos, school and neighborhood data, ...

8613869596835

8613869596835