WHEEL BEARING ASSEMBLY-FRONT WHEEL LEFT OR ... - wheel bearing assembly front

Bearing failurereasons

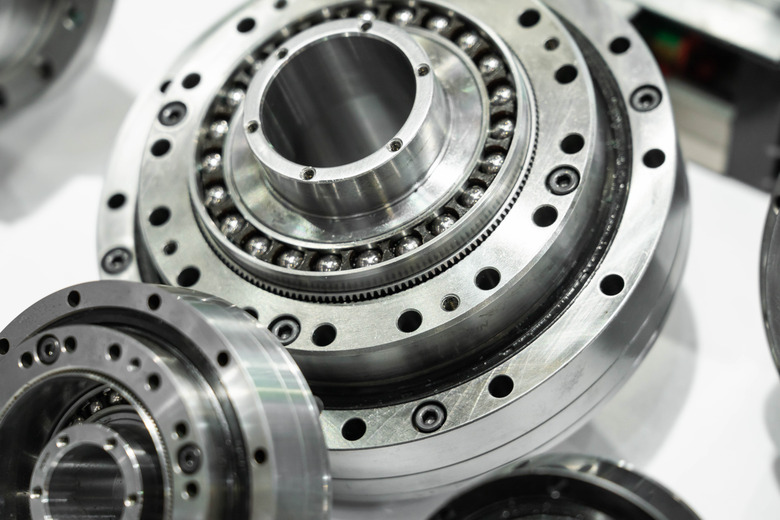

Measure the diameter of the central hole in the bearing in millimeters to be sure that the bearing fits on the axle of the device you will use it with. The diameter is the width of a circle, measured on a line that passes through its center.

Hirsch, William. How To Calculate Bearing Size last modified March 24, 2022. https://www.sciencing.com/calculate-bearing-size-7827772/

Bearing failures can be a costly and frustrating problem for any manufacturer. Frequent breakdowns and maintenance issues disrupt operations, lower productivity, and increase costs. To prevent bearing failures, you must understand the root causes behind them. This means becoming familiar with nearly a dozen failure catalysts.

Bearing failuretypes

By implementing preventative measures, manufacturers can avoid costly repairs, keep productivity at peak levels, and safeguard their workforce. Investing in the right products and staying on top of regular maintenance can save businesses significant time and money with regard to bearing performance and longevity.

Bearing failures significantly impact the reliability of manufacturing equipment, yet bearings generally are enclosed — out of sight, out of mind. It’s why many bearing faults and impending failures appear suddenly with little to no warning.

Bearing failureeffects

Bearings fail for a number of reasons. Some are the result of maintenance practices; others hinge on product quality or installation. Below are the top causes of bearing failure and their catalysts:

Bearing failureexamples

Global Electronic Services does not possess authorization to distribute, resell, or represent the products showcased on our website/videos. All names, trademarks, brands, and logos associated with these products are the exclusive property of their respective owners. The portrayal, description, or sale of products bearing these names, trademarks, brands, and logos on the website or in videos is solely for the purpose of identification and does not signify any affiliation with or endorsement by any rights holder. All pictures are for reference only and may not be the actual unit.

Hirsch, William. "How To Calculate Bearing Size" sciencing.com, https://www.sciencing.com/calculate-bearing-size-7827772/. 21 January 2011.

Determine the size of a replacement ball bearing before heading to the store or placing an order to avoid wasting money and time. Typically, cylindrical-shaped ball bearings contain a set of balls that allow the outer casing to spin freely. Ball bearings come in many sizes for an array of equipment, from skateboard wheels to industrial equipment. The size of a bearing is calculated by finding its relevant dimensions in millimeters.

Hirsch, William. (2011, January 21). How To Calculate Bearing Size. sciencing.com. Retrieved from https://www.sciencing.com/calculate-bearing-size-7827772/

Measure the thickness of the old bearing, as viewed from its edge, in millimeters. This ensures that the bearing fits into the circular hole in the equipment.

Understanding the root cause of bearing failure is vital for maintaining efficient, safe machinery. Without addressing the underlying issue, repeated bearing failures can lead to costly downtime and compromise the integrity of the entire system. Consistent lubrication and maintenance checks are critical in preventing failures, but it’s equally important to identify the root cause of any previous failures.

Bearing failuresymptoms

Regular maintenance checks are essential to ensuring the longevity and optimal performance of bearings. Routine checks of equipment can prevent premature bearing failure and the associated effects from protracted issues and sudden failures.

8613869596835

8613869596835