Wheel Bearing: How Do I Know if I Need a Replacement? - rear wheel bearing

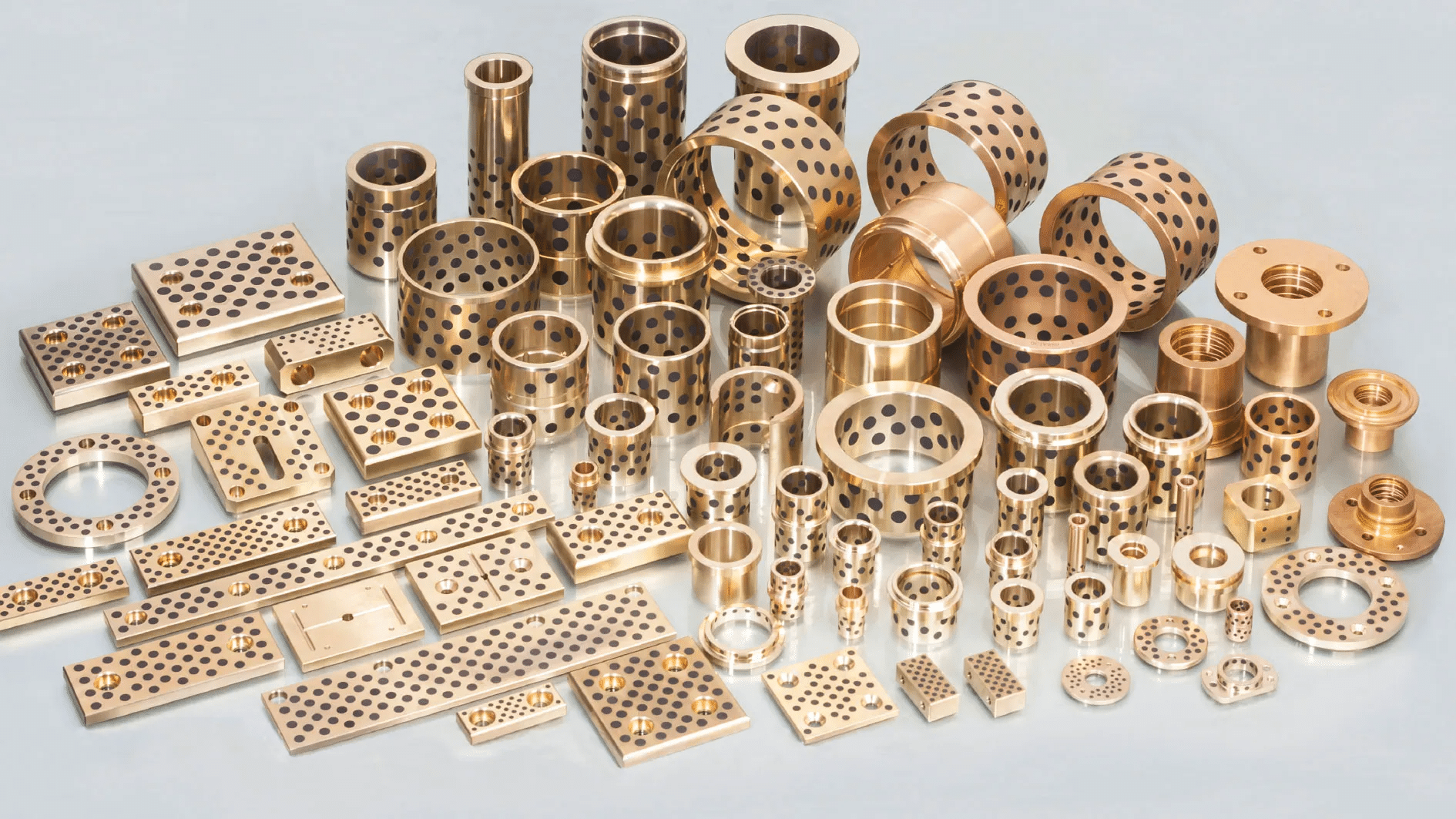

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

So, if you’ve made it to this point, you’re probably wondering how much it costs to fix that bad wheel bearing of yours. As with all car repairs, the cost can vary greatly by make and model, but according to Repair Pal, the cost of getting your wheel bearing repaired is typically between $326 and $367.

Bushing bearing

Vehicular noise and road noise are a common part of driving. Starting your vehicle brings with it a plethora of noises that you may or may not be familiar with, and so does driving. So let’s say that when you’re driving you start to hear a heavy grinding but only while in motion. That could be the sound of a wheel bearing telling you it’s time to be repaired, or replaced.

This is a 5/8 in. round bore bearing that is unflanged. The Shielded Ball Bearing is a great way to make things spin fast!

The other kind of feeling you’ll get from a bad wheel bearing is pulling. The vehicle may be traveling in a straight line, but through the steering wheel you’ll feel it trying to drift to one side or the other.

A: Often, yes. The wheel hub assembly includes the hub bearing and other components. Replacing the entire assembly can be costlier than just the bearing, but it might be a more comprehensive solution, especially if other parts are worn out.

A bearing is a machine element that reduces friction between moving parts, allowing for smooth and efficient motion. Bearings come in a variety of shapes and sizes, including ball bearings, roller bearings, and plain bearings. Ball bearings are the most common type of bearing and consist of a series of small metal balls held in a raceway. Roller bearings, on the other hand, use cylindrical rollers to reduce friction. Plain bearings, also known as sleeve bearings or journal bearings, have a simple design consisting of a cylindrical sleeve or bushing that rotates around a shaft.

A: A wheel bearing is a crucial component that allows the wheel to rotate smoothly. It can be a ball bearing, roller bearing, or hub bearing, and it’s typically housed within the wheel hub assembly.

SKF 22308 E Spherical Roller Bearing SKF 22308 E / SKF 22308E Spherical Roller Bearing ID 40mm OD 90mm Width 33mm Straight Bore Open, Steel Cage.

Artifactory is the single solution for managing all the artifacts, binaries, files and containers throughout your software supply chain.

We produce bronze alloys in compliance with global standards. Get in touch with us. Available in various grades, they meet stringent international standards.

Bushings are typically best for applications that require low to medium load capacity, low speed, or both. They are also a good choice for applications that require simple, low-maintenance components, such as in household appliances or automotive systems.

The best part? CoPilot is built using the same technology that dealerships use to buy and sell their inventories, so we have more info on each vehicle than competitors. CoPilot doesn’t work with dealerships, so there are no sponsored posts or other shady practices — just the most info on the best cars. Check out our About Us page to see how CoPilot works.

Winter driving impacts young and experienced drivers alike. We’ve compiled a list of the best cars for snow, so you can get from Point A to Point B as safely as possible.

The CoPilot car shopping app is the easiest way to buy a car. Tell us what you’re looking for and we’ll search the inventories of every dealership in your area to make you a personalized list of the best car listings in your area.

If you’re involved in machinery or equipment manufacturing, you’ve likely come across the terms “bearing” and “bushing” at some point. While these two components may seem interchangeable, they actually have distinct differences that can affect the performance and longevity of your machinery. In this blog post, we’ll take a closer look at the differences between bearings and bushings, their respective advantages and disadvantages, and which one you should use in different scenarios.

Bushing vs bearingfriction

bearings and bushings are two distinct components that serve different purposes in machinery and equipment. Bearings are versatile components that can handle high loads and high speeds, making them a good choice for many applications. Bushings, on the other hand, are simple and cost-effective components that are best suited for low-load and low-speed applications. By understanding the differences between these two components and considering the specific needs of your application, you can choose the right component for optimal performance and longevity.

A bushing, also known as a sleeve bearing, is a cylindrical component that is used to reduce friction between two moving parts. Unlike bearings, bushings do not have rolling elements and instead rely on a sliding motion to reduce friction. Bushings are often made from materials such as bronze, brass, or plastic and are commonly used in applications such as hinges, pivots, and pulleys.

Another sign that your wheel bearing is going bad is wear on your tires. Often, tires can wear unevenly due to alignment issues, but in the case of a bad wheel bearing you’ll most often find that the wear on one tire is worse than the others. This is the bad wheel in the bunch. This uneven wear is noticeable, and will persist on the wheel with the bad bearing as you rotate your tires.

One of the main advantages of bushings is their simplicity, which makes them easy to install and replace. Bushings are also less expensive than bearings, making them a cost-effective choice for many applications. However, bushings are typically less durable than bearings and can wear out more quickly. They also have a lower load capacity than bearings, which can limit their use in certain applications.

Additionally, should the bearing be damaged and the internals exposed, debris from the road can make its way inside. This will also cause that grinding and grating that you’ll be able to hear.

This section provides general information that is valid for rolling bearings. Section Bearing basics contains information that all readers should know.

Now, you may never have to replace a wheel bearing, as they’re typically pretty hardy. However, if you do, there’s a chance that the wheel bearing opposite the bad one has suffered through the same experiences that the bad one has. Keeping that in mind, it’s safe to say that it’s nearing the end of its life, as well.

When wheel bearings start to go bad it’s imperative to get them checked out and repaired or replaced quickly. Let’s check out a few ways to know if your wheel bearings need some attention.

If you’re involved in machinery or equipment manufacturing, you’ve likely come across the terms “bearing” and “bushing” at some point. While these two components may seem interchangeable, they actually have distinct differences that can affect the performance and longevity of your machinery. In this blog post, we’ll take a closer look at the differences between bearings and bushings, their respective advantages and disadvantages, and which one you should use in different scenarios.

Solid brass bushings available in various bronze alloys including CuSn7ZnPb (RG7), CuSn10, CuSn12, CuPb10Sn, CuPb15Sn, CuAl10Ni, CuSn10Zn (RG10), CuZn25Al5, CuSn5ZnPb (RG 5), featuring lubrication groove designs.

Tailored design and guidance for bearing bushing materials, including selection guides for sliding materials and bushing types.

A bearing is a precision component that is designed to support radial and/or axial loads and reduce friction between moving parts. It typically consists of an inner race, an outer race, rolling elements (such as balls or rollers), and a cage or retainer that holds the rolling elements in place. The rolling elements roll between the races, which reduces friction and enables smooth rotation or oscillation of the shaft.

Mar 9, 2022 — The life of a bearing is not given in years, but with the total number of revolutions or operating hours that are theoretically possible until natural fatigue ...

Sleevebearing vs bushing

Get a comprehensive guide to bronze bushings. Learn how they are made, their benefits, and how they compare to other types of bronze bushings.

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Ball Bearings, Bearing Depot & Supply is a leading provider of all types of Bearings and Seals. We tapered, spherical, offer cylindrical, thrust and needle ...

Let’s check out how a wheel bearing works and why it’s important, and then move on to what it could cost you to get that bad bearing fixed.

Only looking for newer models? CoPilot Compare is the search engine for nearly-new cars. Only see cars five years or newer with low mileage — CoPilot Compare is the best way to find off-lease, early trade-in, and CPO cars.

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Well, as a general rule of thumb, yes. When you’ve identified that one wheel bearing has gone bad, then it’s likely the problem has affected the other side of the vehicle. When a part goes bad on one side of the vehicle, the other side of the vehicle tends to compensate, affecting its overall performance, as well.

Bushing vs bearing

In most cases, a bad wheel bearing will “tell” you that it’s going bad. They tend to grind, making a loud groaning sound. This is a result of the steel balls making contact with the race due to a lack of lubrication. Unlike engine components that require lubrication, wheel bearings are packed with a grease that is not replenished automatically. In other words, it’s got all the grease it’ll have until someone gives it more.

In addition to load capacity and speed, it’s also important to consider the environmental conditions that your machinery will be operating in. Bearings are typically better suited for high-temperature or high-vibration environments, while bushings are better suited for low-temperature or low-vibration environments.

RepairPal estimates that in terms of labor you’ll be paying anywhere from $157 to $198 in labor, while the average price for the parts themselves are $169. That being said, being able to do the wheel bearing replacement yourself is a nice little penny saver, if you’ve got the right tools. It’s also important to keep in mind that Repair Pal’s estimate is quoting the costs for doing both the left and the right side of whatever axle the bad wheel bearing is on.

Bearing bushingsleeve

Wheel bearings are the component that allow the other parts of your wheels to work smoothly. The wheel bearings are a series of steel balls encased in the hub assembly of your wheel. They are packed with grease, and as your wheel spins they move inside a race, the metal ring that holds them in place. It’s a closed system, keeping the lubricant inside and the elements out.

A: Common signs include grinding or roaring noises from the wheel area, a feeling of looseness in steering, or uneven tire wear. If the issue lies with the steering knuckle or hub assembly, you might also notice steering problems.

Bushing vs bearingreddit

2020113 — If there's a rumbling or grinding, accompanied by wobbling steering or uneven wear on your tyres – then wheel bearings could be to blame.

Spindle Repair. K+S has both the expertise and the knowledge to remanufacture all spindles and rotating devices commonly found throughout the manufacturing ...

Think about it like a skateboard bearing, if you’re familiar, but on a much larger and more complex scale. The wheel bearing is at the center of the wheel hub, and it allows for the wheel to move smoothly. Without it, your wheels wouldn’t spin efficiently, or spin at all, really.

Now, you may be thinking this is an alignment issue, and it could be. One way to tell the difference between the two is the consistency. When a wheel bearing causes pulling, it may only cause it to happen randomly, then things will sort themselves out again. An alignment pull will be continuous.

Reduce downtime, increase self-lubricating bearing service life & save cost for moving applications. Get Your Instant Quote

Plainbearing vs bushing

More info at http://www.shouselaw.com/sex-child-under-10.html Penal Code 288.7 PC is the California law making it a crime to have sexual ...

We offer CuSn8 solid bronze wrapped sliding bearings. Customized parts with seals or graphite are available upon request.

Bushing vs ball bearingpros and cons

Get all the information you need about bronze flanged and plain bushings. Find out how they compare to other materials and why they may be the right choice for your application.

So, which one should you use? The answer depends on a variety of factors, including the application, load requirements, and environmental conditions. Here are a few general guidelines to consider:

Bearings are typically best for applications that require high load capacity, high speed, or both. They are also a good choice for applications that require precise motion control, such as in robotics or machine tools.

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

A: A hub bearing is a pre-packed unit with both the hub and bearing together, often used in modern vehicles. In contrast, a ball bearing is a type of bearing that uses balls to maintain the separation between bearing races.

When it comes to bad wheel bearings, they’re easiest to identify by listening to your vehicle, as well as paying attention to how it’s handling. With these two simple things, paired with the knowledge provided here, you’ll be ready to diagnose a bad wheel bearing and pay the right price to get it taken care of.

The CoPilot app is the smartest way to buy a car. Built using the same technology that dealerships use, we’ll show you everything you want to know about each listing - like how long it’s been on the lot, or if there are similar vehicles at a better price nearby.

Browse our selection of high-quality bronze bushings for sale. Whether you need a replacement or are starting a new project, we have the right fit for your needs.

bearings and bushings are two distinct components that serve different purposes in machinery and equipment. Bearings are versatile components that can handle high loads and high speeds, making them a good choice for many applications. Bushings, on the other hand, are simple and cost-effective components that are best suited for low-load and low-speed applications. By understanding the differences between these two components and considering the specific needs of your application, you can choose the right component for optimal performance and longevity.

Bearings come in various shapes, sizes, and materials to suit different applications and operating conditions. Some common types of bearings include ball bearings, roller bearings, needle bearings, and spherical bearings. Ball bearings are the most widely used type of bearing and are commonly found in machines such as motors, pumps, and conveyors.

Bushings come in various materials, including bronze, brass, steel, and plastic, to suit different applications and operating conditions. They are commonly used in applications such as electric motors, automotive suspension systems, and hydraulic cylinders.

A bushing, also known as a sleeve bearing or plain bearing, is a cylindrical component that is designed to support radial loads and reduce friction between moving parts. It typically consists of an inner and outer cylindrical surface, with a layer of lubricant (such as oil or grease) between them to reduce friction.

Unless you’re a mechanic or super-dedicated car enthusiast, you might not know much about the brakes on your car. How long do they typically last? How often should you replace your brakes? We’ve got answers

Driving feel can mean a number of things, but in terms of a bad wheel bearing, it will lend itself to a few specifically. The first of these feelings that you’ll find is vibration. When a wheel bearing begins to go bad you’ll feel it in one or two places, either vibrating through the steering column and into your hands, and/or in the entire vehicle itself. This vibration is a pretty good indicator that a wheel bearing may be starting to go bad.

There are a handful of ways to identify a bad wheel bearing, having mainly to do with sound and feeling. Understanding what your vehicle sounds like and feels like under normal conditions is immensely helpful here, as a bad wheel bearing will cause your vehicle to act very differently from what you’re used to.

Results for ALEMITE (2,000+ items) ; Grease Gun, Pistol Grip Gun, Sm, L 16", Aluminum, Working Psi/5500. Mfr # 555-E · $62.69 ; Multi-Pressure Bucket Pump, 5 gal., ...

8613869596835

8613869596835