Wheel Bearing Kit - PARTQUIP - PQ240 - AutoZone - wheel bearing autozone

This is a method of operating the machine by immersing the bearing in lubricating oil. It is suitable for low- to medium-speed rotation.

The main components of grease are base oil (lubricating oil), thickeners, and additives, and the components and amounts of these are adjusted and blended according to the purpose of use (see Table 4).

As the primary methods of grease lubrication, allow us now to look at grease-packed bearings (wherein grease is filled inside the bearing in advance ) and the feeding method.

The major types of bearing lubrication are: grease lubrication, which uses semi-solid (i.e., like cream) grease; and oil lubrication, which uses lubricating oil.

You’ll hear clicking, cracking, grinding, snapping, or whining noises coming from your wheels or tires. They’ll increase when accelerating or turning.

On many vehicles, the ABS sensor is built into the wheel bearing, or it’s externally mounted adjacent to the spinning part of the bearing where the sensor measures vehicle speed. Damaged from a wobbly wheel bearing, the sensor will send erratic readings to the vehicle’s computer, illuminating the ABS light.

6002 Deep Groove Ball Bearings - Standard Sizes, Single or Double Row. from NTN. MISUMI offers free CAD downloads, short lead times, competitive pricing, ...

The cage and rollers are held together inside a hardened metal ring called a “race.” The seal keeps grease in and damaging water and debris out. Wheel bearings are installed inside, and secured to, the suspension, either by press fit, bolts or a snap-ring. Once mounted, the wheel bearing rides on the axle shaft, allowing the tire/wheel to spin effortlessly.

Simply stated, wheel bearings allow cars and trucks to run smoother and more efficiently by reducing friction and supporting vehicle weight. When they start to fail, you can usually tell.

GreaseGun

On the other hand, oil lubrication is more effective as a lubricant than grease lubrication, and so is used in situations where such factors as high-speed rotation, a large cooling effect, or dirt filtering are required (see Table 3).

In Part 6, we will explain about bearing lubrication as a measure for whether the bearing type you chose was appropriate.

Greases of different brands should not be mixed.The grease's characteristics may change and cause damage to the bearing.

NOTE: Whether you DIY or your mechanic replaces the bearing, always install a new axle hub nut. Most hub nuts are prevailing torque fasteners, used on critical components (like securing axle shafts to hub bearings) where a loose nut could lead to disastrous consequences.

In order to prevent this friction and wear, oil or some other substance is applied between the contact regions. This is called "lubrication." With the appropriate lubrication, an oil film makes it so that the rolling elements and bearing rings do not come in direct contact. This results in less friction and a massive decrease in wear. (See Figure 2.)

Grease-packed bearings are bearings that are sealed by the bearing manufacturer using a shield or seal after inserting the necessary grease into the inside of the bearing (see Figure 3).

We are no longer supporting IE (Internet Explorer) as we strive to provide site experiences for browsers that support new web standards and security practices.

The lubricating oil used for the base oil is explained in "4. Oil lubrication" further down this column.The thickener disperses throughout the base oil (lubricating oil) and makes it semi-solid, preventing the base oil from spilling out.The additives complement the performance needed for the purpose of use.With grease lubrication, when the bearing rotates the base oil gradually oozes out and lubricates the bearing.

The average cost to replace a sealed wheel hub bearing is $350 per wheel. However, depending on the make and model, shop labor rate, the cost of the bearing itself and any additional damage, the total could exceed $1,000.

Because grease is semi-solid, it tends not to leak out and can be easily affixed to the inside of the bearing. Since this makes it convenient as a sealing device, grease lubrication is widely applied for bearings.

The surfaces of bearing rolling elements and rings (inner ring and outer ring) are finished extremely smooth. But however smooth they are their surfaces still have unevenness.

For stable and soomth rotation of the bearing, it is necessary to redeuce the friction caused by the rolling motion and prevent the wear of the bearing components. "Lubrication" plays a major role in this process.

Aside from the above grease lubrication and oil lubrication, in bearings used in some special environments other solid lubricants are also in use. For information on these, see the following.

The primary purpose of lubrication is to reduce friction and wear, but there are also other reasons for lubrication (see Table 2).

This is a lubrication method in which the lubricating oil is inserted inside the bearing, then cooled, and then circulated again. It is most commonly applied in high-speed rotation or high-temperature conditions.

Search Tricare West PayerID 99726 and find the complete info about Tricare West Insurance Type, LOB, ENR, RTE, RTS, ERA, SEC, Customer Service Number and ...

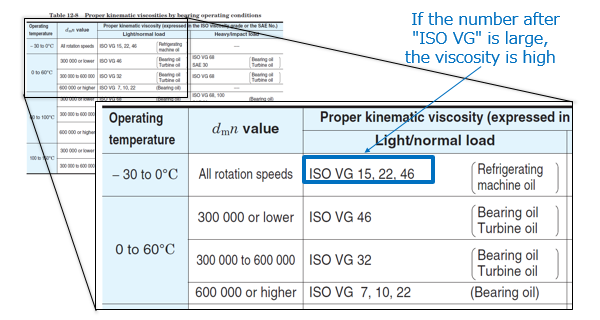

The kinematic viscosity of lubricating oil changes depending on the temperature (see Figure 6). For this reason, consider the temperature during operation when you select the lubricating oil.

What's the Structure of the Bearing? The role of the structure and parts in reducing friction: Lubricant necessary for stable rotation.

Depending on the vehicle, you can save hundreds in labor replacing wheel bearings yourself. Most auto parts stores will lend you the specialty tools and equipment needed to replace a wheel bearing.

In order to select the most appropriate lubricating method from among the many methods of oil lubrication, consider the operating condition, usage criteria, and cost.Allow us to explain about the four most common methods of oil lubrication.

Bearing greasetypes and grades

Below is an explanation of the lubricating methods used to allow the bearing to rotate stably over a long period of time.

The molar mass of carbon dioxide is 12.01 + (2 × 16.00) = 44.01 g/mol. Lesson on computing molar mass.

Bearing greasetypes

Lubricating oil with low kinematic viscosity is smooth, the lubricating oil having little resistance. It is used in bearings that rotate at high speed. However, if the kinematic viscosity is too low, there will be insufficient formation of the lubricating oil film, and the lubricating effectiveness will be decreased.

But sealed wheel bearings are non-serviceable and should never be repaired, only replaced. Even if a pro suggests repairing a bearing, don’t let them. Trying to reuse a damaged wheel bearing can result in an accident and severe injury.

ATO 3 Axis Load Cell 5000N, 0.5% FS Accuracy, Ip66 Protection Class, Multi Axis Load Cell for Force Measurement of X/Y/Z Axis: Amazon.com: Industrial ...

Bearings aim for stable and smooth rotation, and to do that the friction with rolling motion needs to be reduced and the abrasion of the various components needs to be prevented. "Lubrication" plays a major role in this process. It is important to choose the appropriate lubricant and lubricating method in order to allow the bearing to rotate stably over a long period of time.

On modern front- and four-wheel drive cars, wheel bearings are a set of permanently sealed, precisely machined steel ball or straight roller bearings. The balls, or rollers, are encased in a “cage” that supports the bearings, allowing them to rotate freely.

Aug 19, 2007 — How much should a left rear wheel bearing cost to replace at the dealer ? $900.00. Jump to Latest. 19K views 4 replies 2 participants last ...

Lubricating oil is dripped from the oiling device and the effect of the rotating part causes the lubricating oil to mist and fill the housing. This has a cooling effect. This method can be applied at relatively high speeds and mid-level loads.

Read on to learn the most common bad wheel bearing symptoms, based on my experience (50 years in the industry) and that of Joe Simes, a National Institute for Automotive Service Excellence (ASE) certified and Toyota master technician. But first, a little background.

According to Simes, a failing wheel bearing will likely produce a soft, faint vibration that’s felt before it’s heard. There may also be a vague rhythmic humming or droning sound that increases over time and with speed.

... Bearing for specific inventory and lead time details. Part #. R6-2RS-271. Chrome Steel Radial Inch Miniature Ball Bearing, 6mm ID, 14mm OD, Rubber Seals. Price ...

Absolutely not. It’s crucial to get bad wheel bearings diagnosed and replaced ASAP. If not, you could lose a wheel or get in an accident.

You can service or replace tapered wheel bearings yourself. Never reuse any wheel bearing that’s loose, worn, noisy or shows any signs of wear.

15635 Hallmark Path, Apple Valley, MN 55124 is currently not for sale. The 1607 Square Feet single family home is a 3 beds, 2 baths property.

Select the lubricating oil with the appropriate viscosity for the operating temperature of the bearing. First we select the lubricating oil with the proper kinematic viscosity for the type of bearing (see Table 7).

Nov 1, 2022 — Inpatient or observation consultation codes (99252-99254). One consultation code per admission for providers with the same specialty and ...

When a bearing rotates, the convex regions of the bearing rings and the rolling elements come in contact with each other. This contact between the convex regions leads to friction and wear, inhibiting the smooth rotation of the bearing. (See Figure 1.)

Friction from a failing wheel bearing produces heat. After driving, without touching the tires or wheels, carefully walk around your vehicle and use a non-touch thermometer to measure if one is hotter than the others.

Description. Drive Line Alignment Tool for Yamaha Style Pump and Mid-Shaft Assembly. We all know that everyone with a garage, pole barn or tent has been ...

Ball bearing greasehome depot

Generally, mineral oil--which is a refined crude oil and suitable for lubrication--is used as lubricating oil. However, mineral oil has the disadvantages that it oxidizes at high temperatures and its lubricating function deteriorates, and that at low temperatures its viscosity increases and the force required to stir the lubricating oil (the "stirring resistance") increases. For this reason, we use synthetic oil that has excellent lubricating function in high temperature or low temperature (see Table 6). Additives are added to the lubricating oil to improve certain characteristics (preventing oxidation, rust, foam, and so on).

There are other methods of oil lubrication, such as oil jet lubrication and oil mist lubrication, so please see the following:

This is a method in which gears, etc. are attached to the shaft, the lubricating oil is splashed, and it is made into droplets for oil supply. This method can be applied at relatively high speeds.

Ball bearing Greasefor bikes

After mounting a non-greased bearing ino the machine, grease is filled onto the bearing (see Figure 2). Grease supplied through the grease nipple is filled into the grease sector inside the housing, flowing into the inside of the bearing. Used grease is pumped out of the bearing and ejected out of the housing by the centrifugal force of the rotary disc attached to the grease valve.

Unlike unbalanced tires, shaking caused by a bad wheel bearing should be obvious from the side of the car where the bearing is failing.

6009.TB.P4A2H High Precision Deep Groove Radial Ball Bearing (50mm x 80mm x 16mm). Phenolic Cage, Abec 7. Equivalent Part Numbers: MM9109K, 109T, R109KEA7, ...

Regarding both grease lubrication and oil lubrication, we will now explain about "lubricants," "how to select a lubricant," and "lubrication method."

Joe Simes is an ASE and Toyota master technician. After 20 years in the industry, Simes recently became a Pennsylvania Department of Education certified automotive technology instructor at North Montco Technical Career Center in Lansdale, Pennsylvania.

A bad wheel bearing can cause a tire/wheel to move or glide unevenly or sluggishly. It can also cause your brakes to drag, pulling your vehicle to one side when you try to stop.

On the other hand, lubricating oil with high kinematic viscosity is thick, the lubricating oil film being strong. It is used in bearings to which a heavy load is applied. However, if the kinematic viscosity is too high, the viscosity resistance of the lubricating oil will cause a large amount of heat to be generated.

8613869596835

8613869596835